Method and apparatus for diagnosing a crankcase ventilation line of an internal combustion engine

A technology for crankcase ventilation and internal combustion engines, which is applied in crankcase ventilation, internal combustion piston engines, combustion engines, etc., and can solve the problems of reduced expected service life, increased wear and failure of internal combustion engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

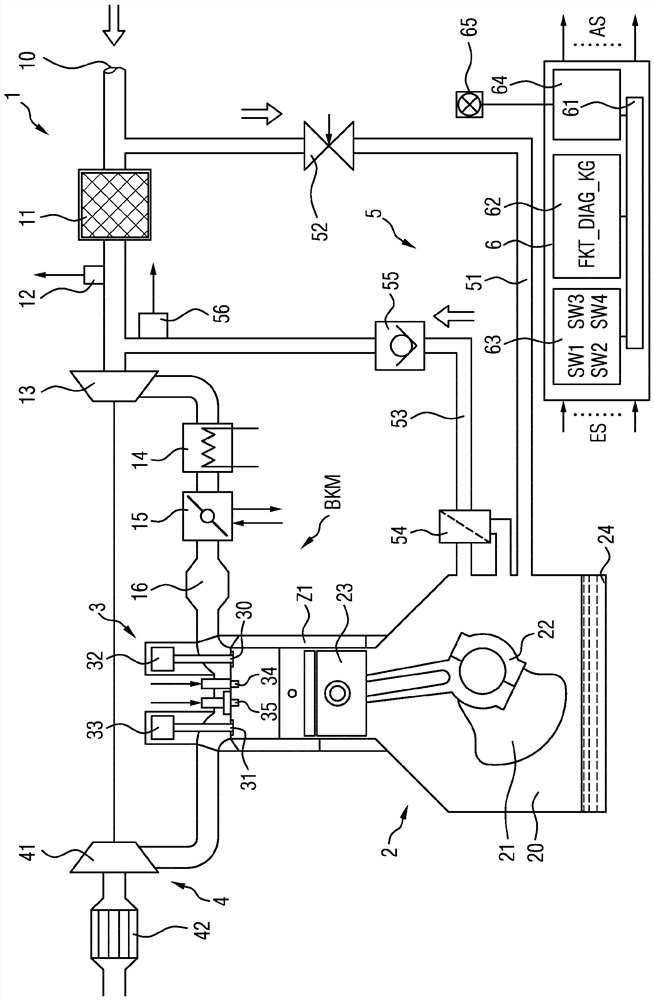

[0021] The internal combustion engine BKM comprises an intake port 1 , an engine block 2 , a cylinder head 3 and an exhaust port 4 .

[0022] In the flow direction of the intake air and starting from the intake opening 10, the intake duct 1 comprises in succession an air filter 11, an air mass flow meter 12 as a load sensor, a compressor 13 of the exhaust gas turbocharger, a charge air cooling 14, throttle valve 15, intake pipe 16 leading to cylinder Z1 via the intake duct in engine block 2. Additional sensors in the intake duct 1 required for the BKM operation of the internal combustion engine are not shown. Throttle valve 15 is preferably in the form of a throttle element (E-Gas) controlled by an electric motor, which, in addition to being actuated by the driver (driver request), can also be controlled via an electronic control unit depending on the operating zone of the internal combustion engine BKM 6 to adjust the opening cross-section of the throttle element. At the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com