Secondary impact hydraulic breaking hammer

A technology of hydraulic breaker and buffer spring, used in impact drilling, construction, drilling equipment and methods, etc., can solve the problems of limited effect, insufficient frequency, and unsatisfactory impact process, so as to improve the crushing efficiency and effect. , Improve the service life and achieve the effect of secondary impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

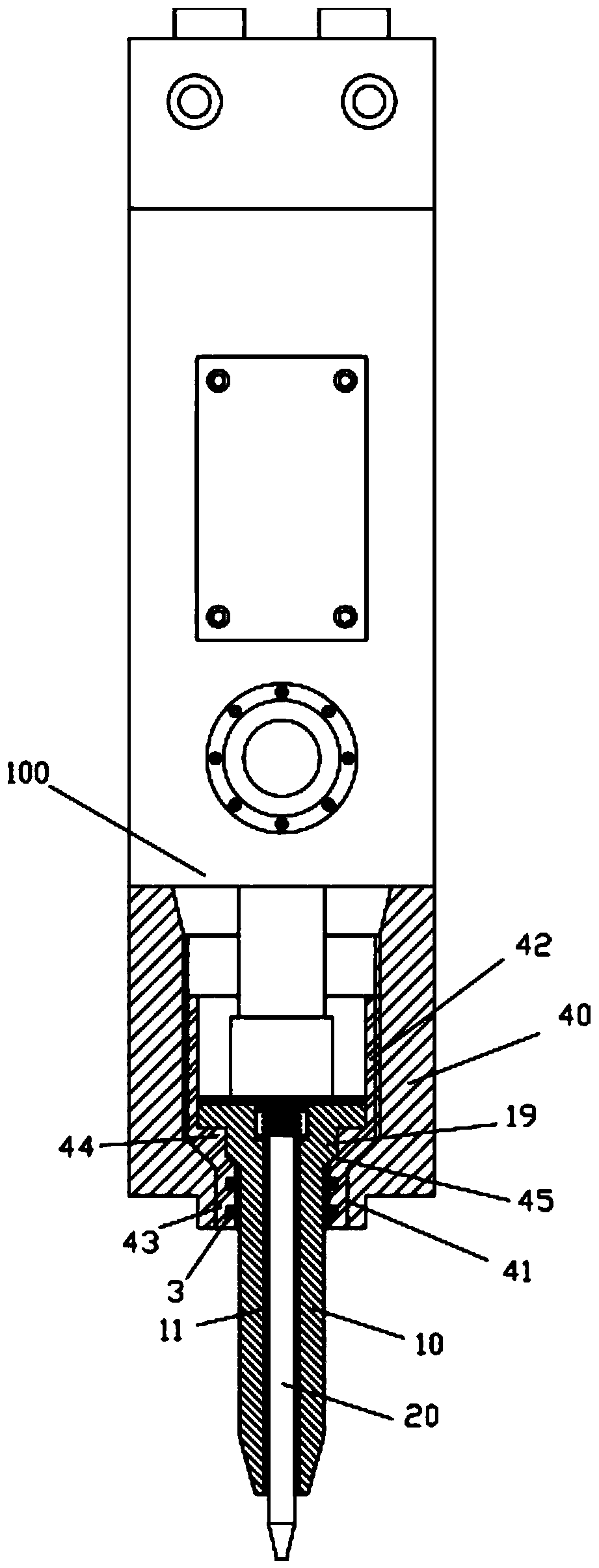

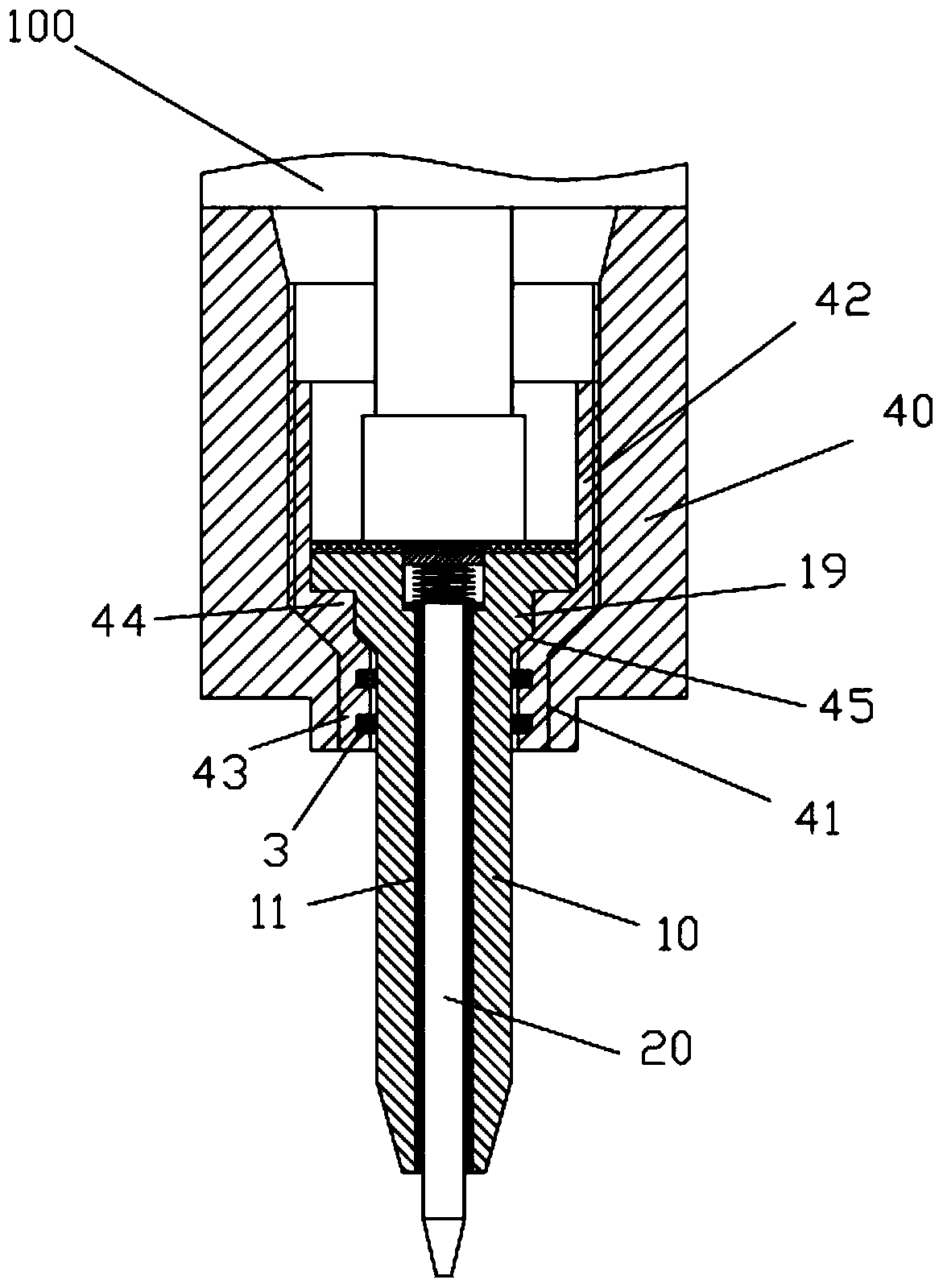

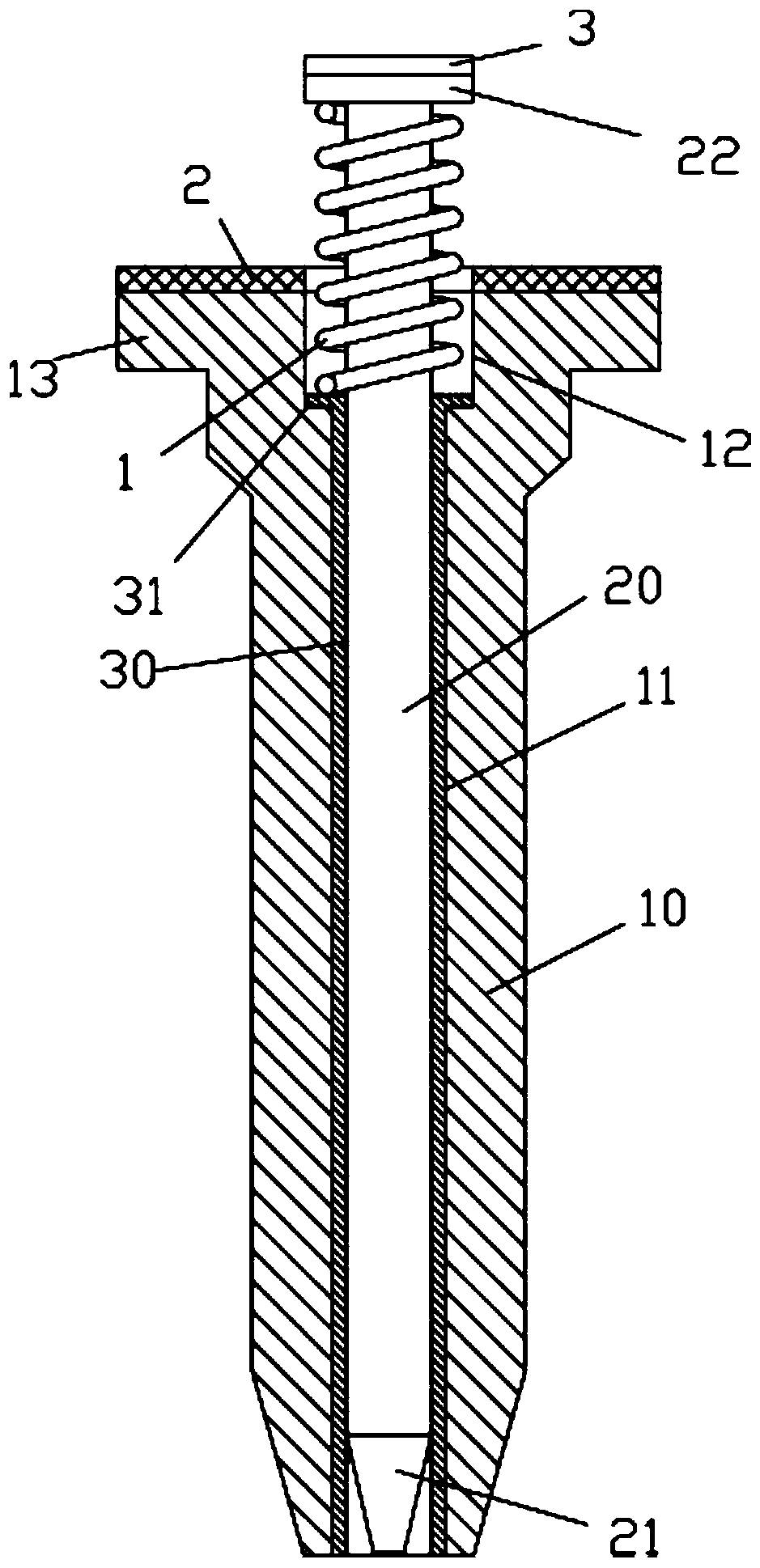

[0020] Examples, see e.g. Figure 1 to Figure 3 As shown, a two-stage impact hydraulic breaker includes a middle shell 100 of the hydraulic breaker, a front shell 40, a hydraulic main drill rod 10 and a middle drill rod 20, and the front shell 40 is fixed on the bottom surface of the middle shell 100 Above, the middle part of the bottom plate of the front housing 40 is formed with a central through hole 41, the main drill rod 10 is inserted into the central through hole 41, the inner side wall of the front housing 40 is formed with internal threads, and the inner reinforcing sleeve The body 42 is screwed into the internal thread, the main drill rod 10 is inserted into the inner reinforcement sleeve 42, and the lower raised sleeve 43 of the inner reinforcement sleeve 42 is inserted into the middle through hole 41;

[0021] The middle part of the main drill rod 10 is formed with an axial vertical through hole 11, the middle drill rod 20 is inserted into the axial vertical throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com