Fixing device for wall hanging piece

A technology of fixing devices and pendants, which is applied in the direction of connecting components, material gluing, suction cups, etc., can solve the problems of weak adsorption force on the base surface, short service life, and inability to hang heavy objects for a long time, so as to ensure the negative pressure adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

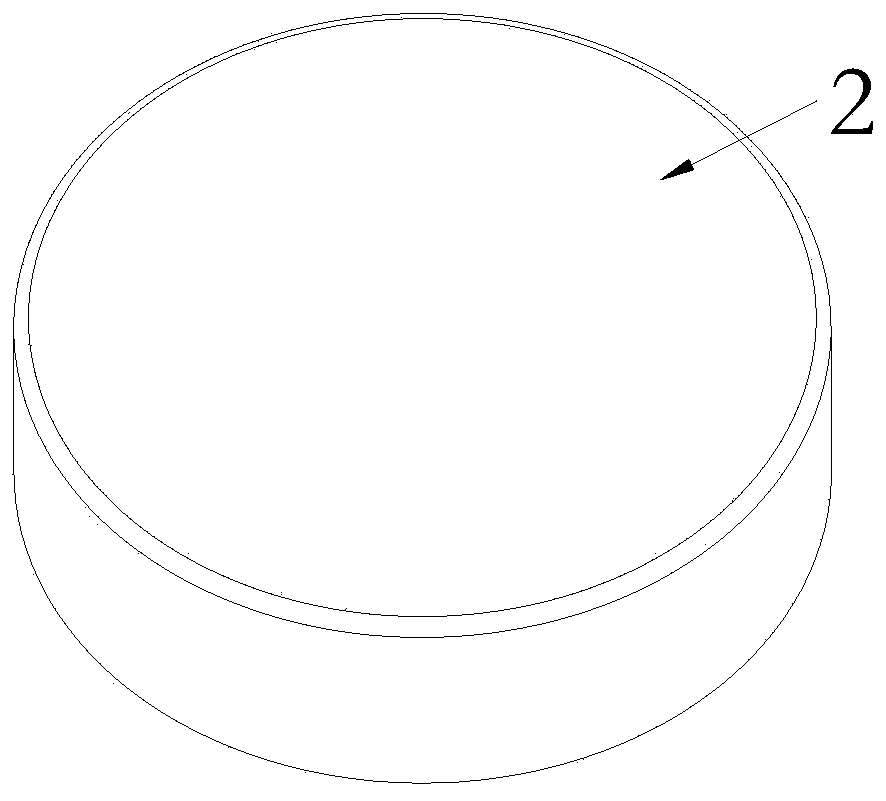

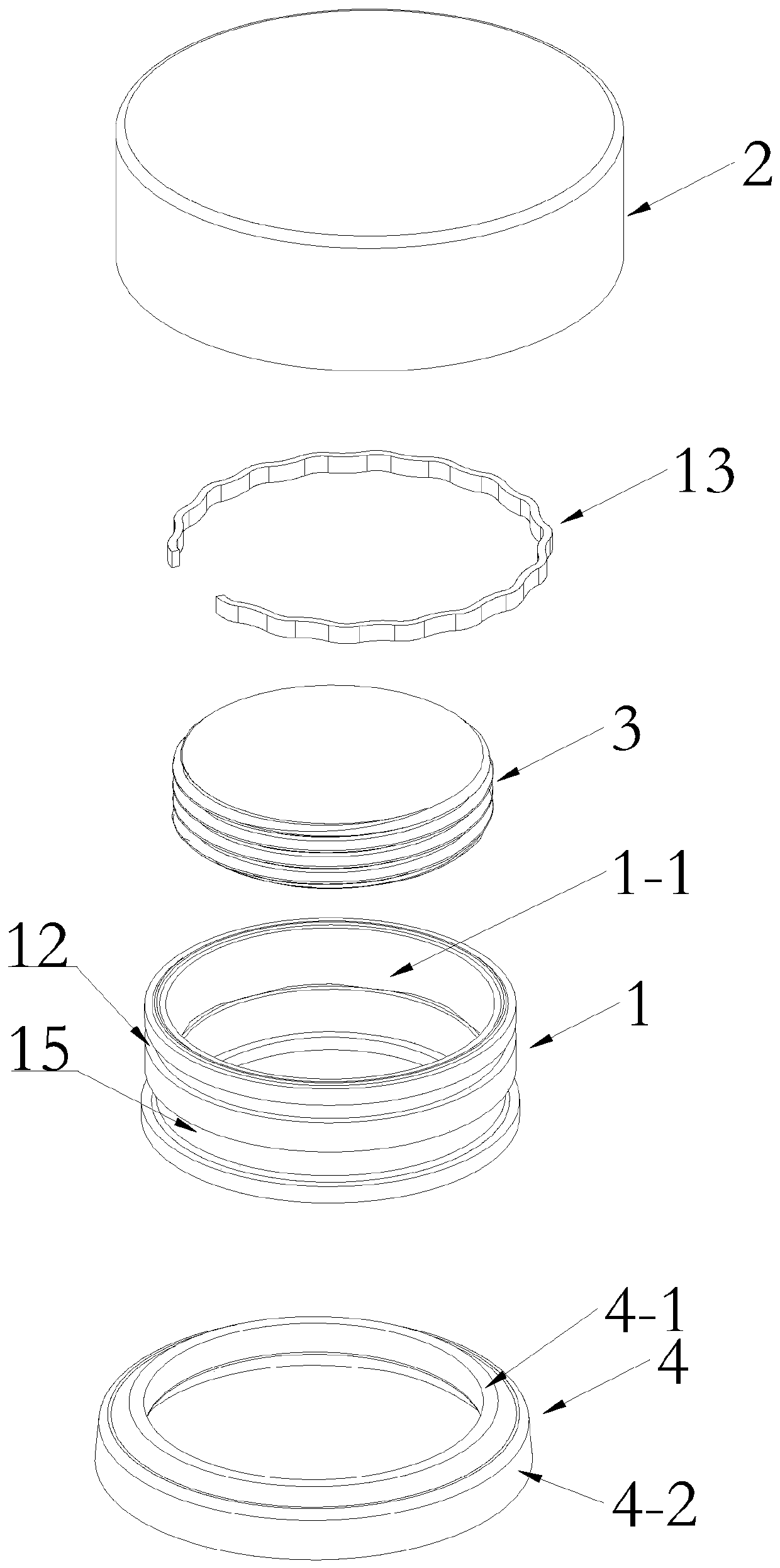

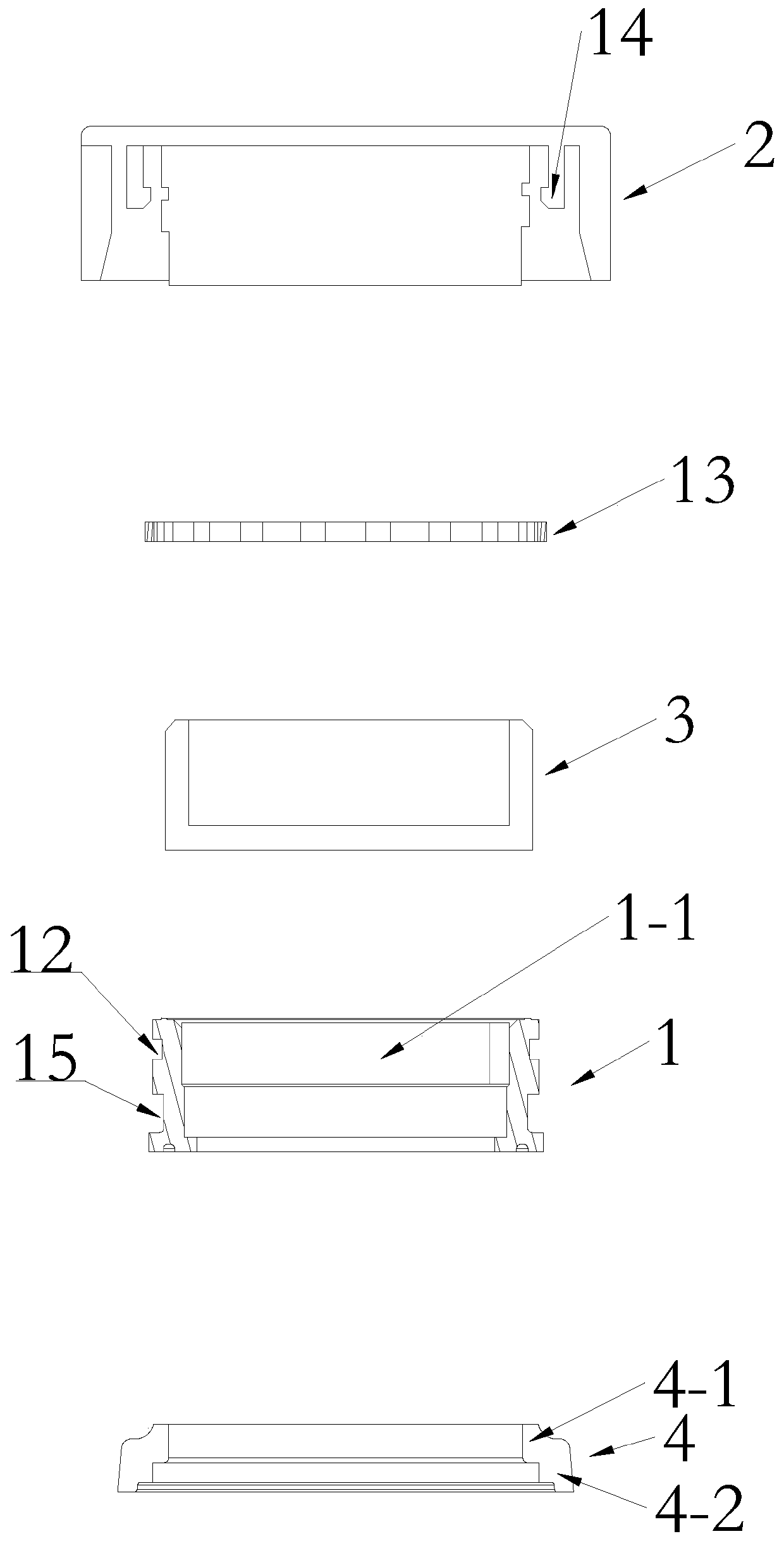

[0024] Such as Figure 1-3 As shown, a fixing device for a wall hanger includes a fixing base 1, and a base shell 2 is provided on the fixing base 1, and the housing of the base shell 2 is connected with a The adhesive part 3 on the base surface of the body, the bottom end surface of the adhesive part 3 is coated with colloid, the colloid in this embodiment is liquid and semi-solid glue, and at the same time, there is a first embedding on the fixed base 1. The joint channel 1-1, the adhesive part 3 is hermetically fitted in the first fitting channel 1-1, and the bottom end surface of the adhesive part 3 extends at least to the base surface of the bottom end of the fixed base 1, through The adhesive part 3 passes through the fixed base 1 and is bonded and fixed to the base surface of the wall. At the same time, a gasket can be provided between the adhesive part 3 and the first fitting channel 1-1 to ensure that the adhesive part 3 can be sealed. Fitted in the first fitting cha...

specific Embodiment 2

[0026] Such as Figure 4-6 As shown, the difference between this specific embodiment and specific embodiment 1 is that a second fitting channel 1-2 is opened on the fixed base 1, and a corresponding adhesive part 3 is provided in the base shell 2. The ring groove 5 of the adhesive part 3 can be embedded, and the ring groove 5 is located in the second fitting channel 1-2. In addition, a connecting ring is provided between the outer wall of the ring groove 5 and the second fitting channel 1-2. 6, the connecting ring 6 can be raised and lowered on the outer wall of the ring groove 5, a sealing gasket 7 is provided between the inner wall of the connecting ring 6 and the ring groove 5, and the outer wall of the connecting ring 6 and the second There is a sealing ring 8 between the two fitting channels 1-2, and the ring groove 5 integrally formed with the base shell 2 is threadedly connected to the connecting ring 6, so that the connecting ring 6 can move up and down when the base s...

specific Embodiment 3

[0030] Such as Figure 7-8 As shown, this specific embodiment is based on the specific embodiment 2. The top of the base shell 2 is provided with a docking groove 9 communicating with the ring groove 5 corresponding to the ring groove 5, and a pressing groove 9 is embedded in the docking groove 9. Part 10, the pressing part 10 is screwed to the end of the adhesive part 3, and a sealing part 11 is provided between the pressing part 10 and the docking groove 9;

[0031] Specifically, in order to make the fixing device applicable to various wall hangings, the pressing member 10 can be a button for assisting installation and fixing (such as Figure 7 shown), it can also be the butt joint of the wall pendant (such as Figure 8 As shown), it can be applied and hung with various wall pendants by replacing the pressing parts.

[0032] In addition, if Figure 9 As shown, the adhesive member 3 is directly screwed into the first fitting channel 1-1 or the second fitting channel 1-2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com