Occupational hygiene testing equipment for food production

A detection equipment and professional technology, which is applied in the field of food occupational hygiene detection, can solve the problems of reducing the service life of noise detection equipment, reducing the sensitivity of detection probes, and consuming a lot of time, so as to save time, ensure sensitivity, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

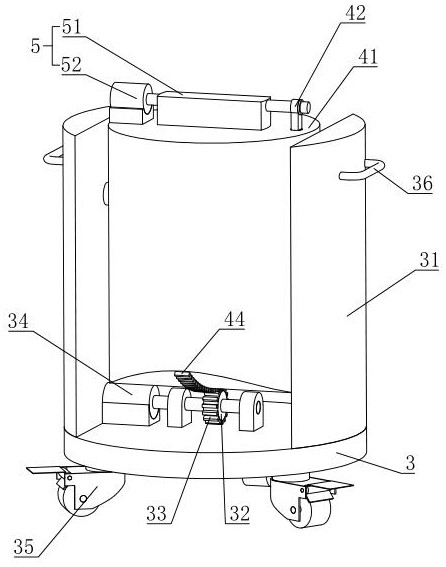

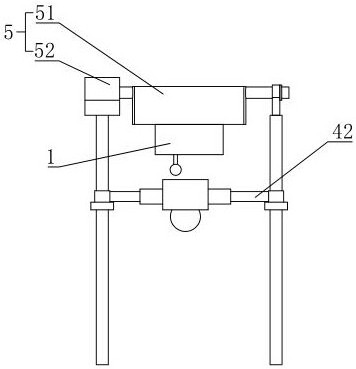

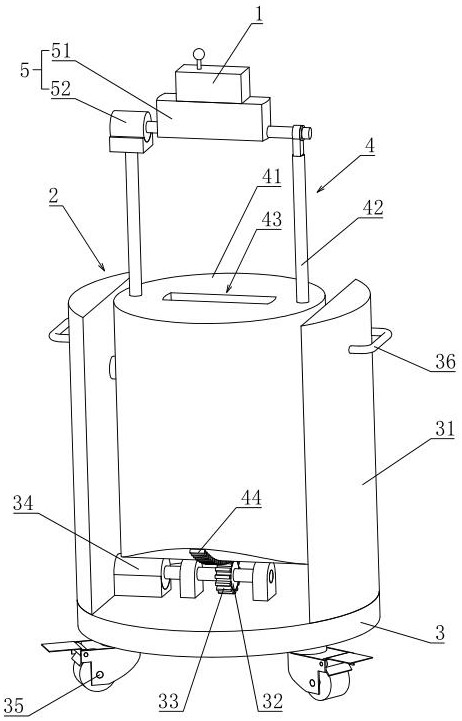

[0021] Such as Figure 1-3 As shown, it is a kind of occupational health detection equipment for food production disclosed by the present invention, which includes a noise detector 1 and a fixing device 2. The fixing device 2 includes a fixing plate 3, a support assembly 4 and a turning assembly 5. The support assembly 4 is installed on a fixed On the plate 3, the support assembly 4 includes a support cylinder 41 and two linked electric screw lifters 42. The support cylinder 41 is a cylindrical cylinder with a cavity and the upper end surface of the support cylinder 41 is provided with an accommodation port 43 communicating with its inner cavity. The motor of the screw lifter 42 is fixedly connected to the side wall of the inner cavity of the support tube 41, the screw mandrel of the electric screw lifter 42 passes through the upper end surface of the support tube 41, and the turning assembly 5 includes a mounting plate 51 and a turning motor 52, and the turning motor 52 is fix...

specific Embodiment approach

[0025] When performing noise detection, the detection device is moved to the noise detection location through the handle 36, and the universal wheel 35 is locked. The electric screw lifter 42 drives the overturn assembly 5 to move upward along the axis of the support cylinder 41, and the overturn motor 52 drives the mounting plate 51 to rotate clockwise by 180°. According to the direction of the noise source, the drive motor 34 drives the support cylinder 41 to rotate, thereby Adjust the angle of the noise detector 1.

[0026] After the noise detection is completed, the turning motor 52 drives the mounting plate 51 to rotate counterclockwise by 180°, the electric screw lifter 42 drives the turning assembly 5 to move downward along the axis of the support tube 41, and the noise detector 1 is stored in the support tube 41. cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com