A bag filter

A bag dust collector and bag technology, applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of low and frequent dust removal work, achieve improved dust removal efficiency, efficient dust removal work, and reduce adhesion speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

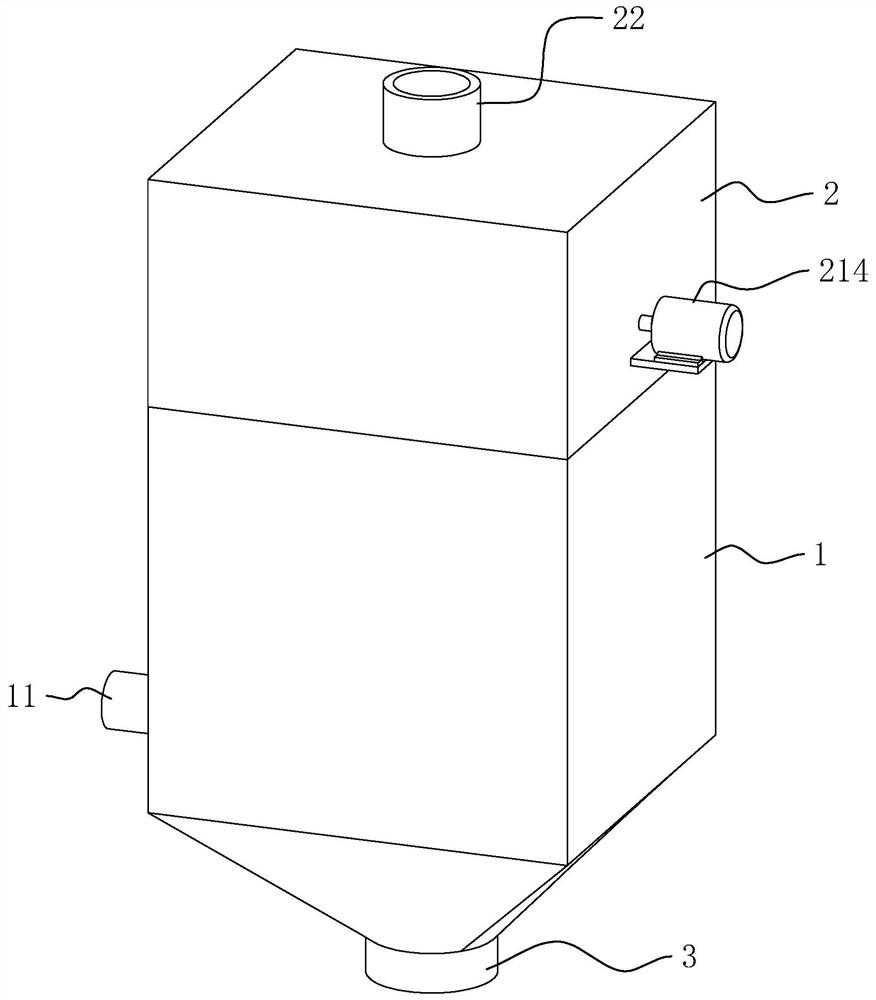

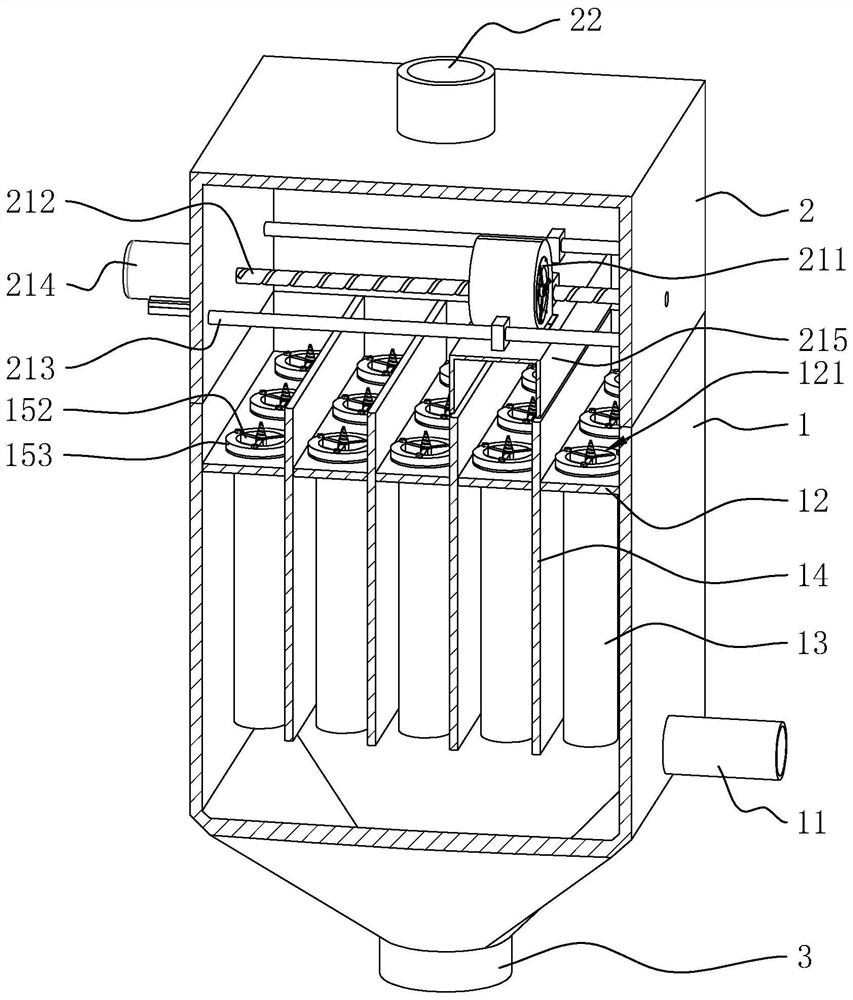

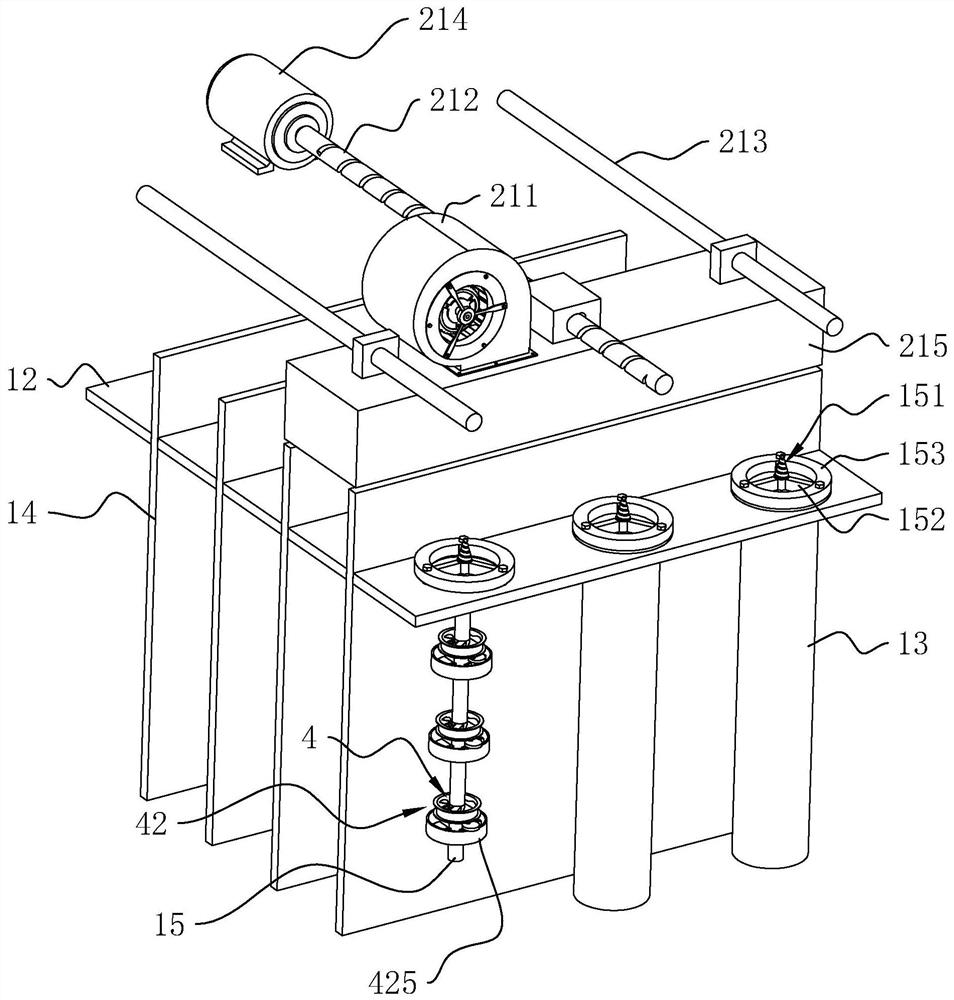

[0039] refer to figure 1 and figure 2, is a bag filter disclosed in the present invention, which includes a dust removal box 1, and a first channel 11 is fixed on one side of the dust removal box 1. An upper box body 2 is fixed above the dust removal box body 1 , and a second channel 22 is arranged above the upper box body 2 . The lower end of the dust removal box body 1 is funnel-shaped, and a dust discharge device 3 (prior art) is fixed at the bottom end. A horizontal fixing plate 12 is fixed inside the dust removal box 1, and a number of evenly distributed through holes 121 are arranged on the fixing plate 12 (the number of through holes 121 in this embodiment is set to 15). The through-hole 121 is provided with a dust-removing bag 13, and the opening of the dust-removing bag 13 is pressed against the fixed plate 12 by a mounting ring 153. plate 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com