Flip type ultrasonic cleaning method for pcb printed circuit board

A printed circuit board and ultrasonic technology, which is applied in the field of flip-type ultrasonic cleaning of PCB printed circuit boards, can solve the problems of staff injury, high labor intensity, and low cleaning efficiency, and achieves convenient operation and use, high degree of automation, and structural ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

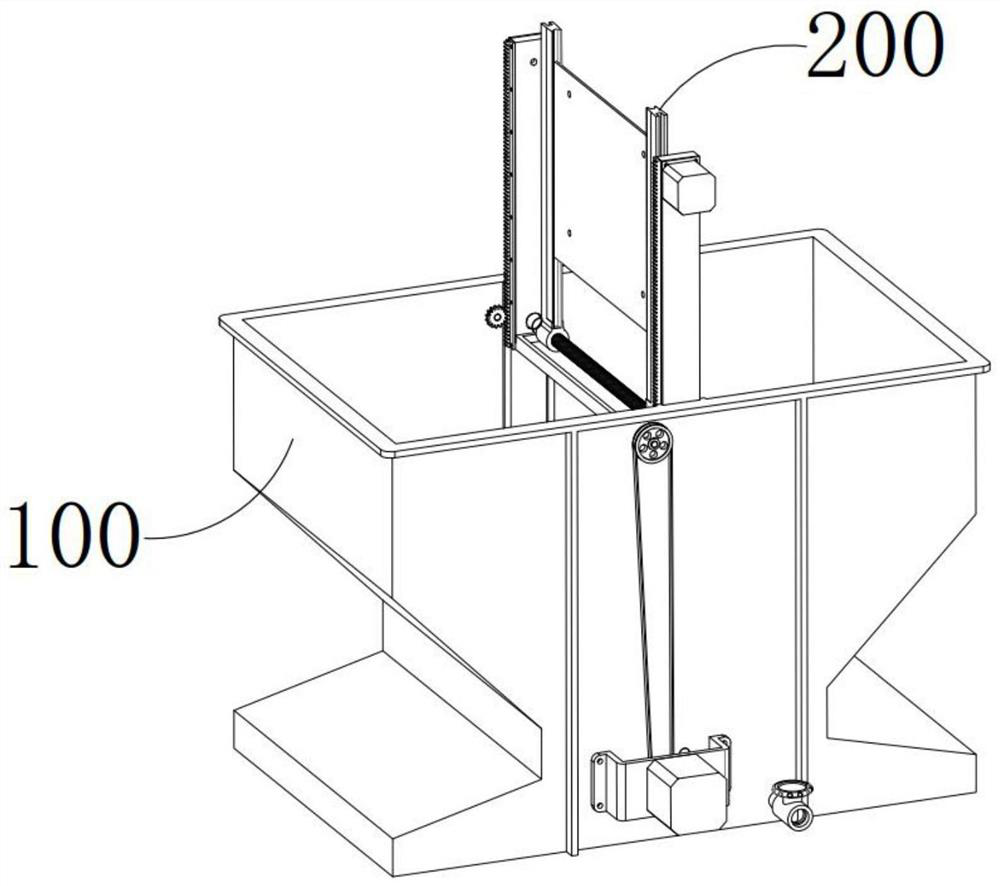

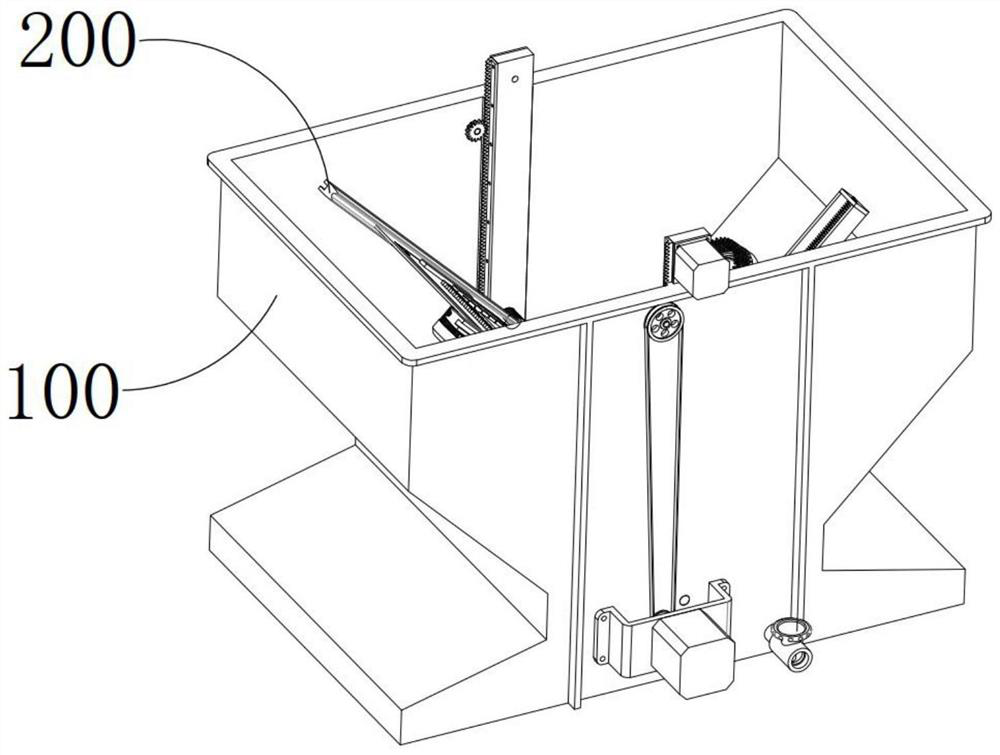

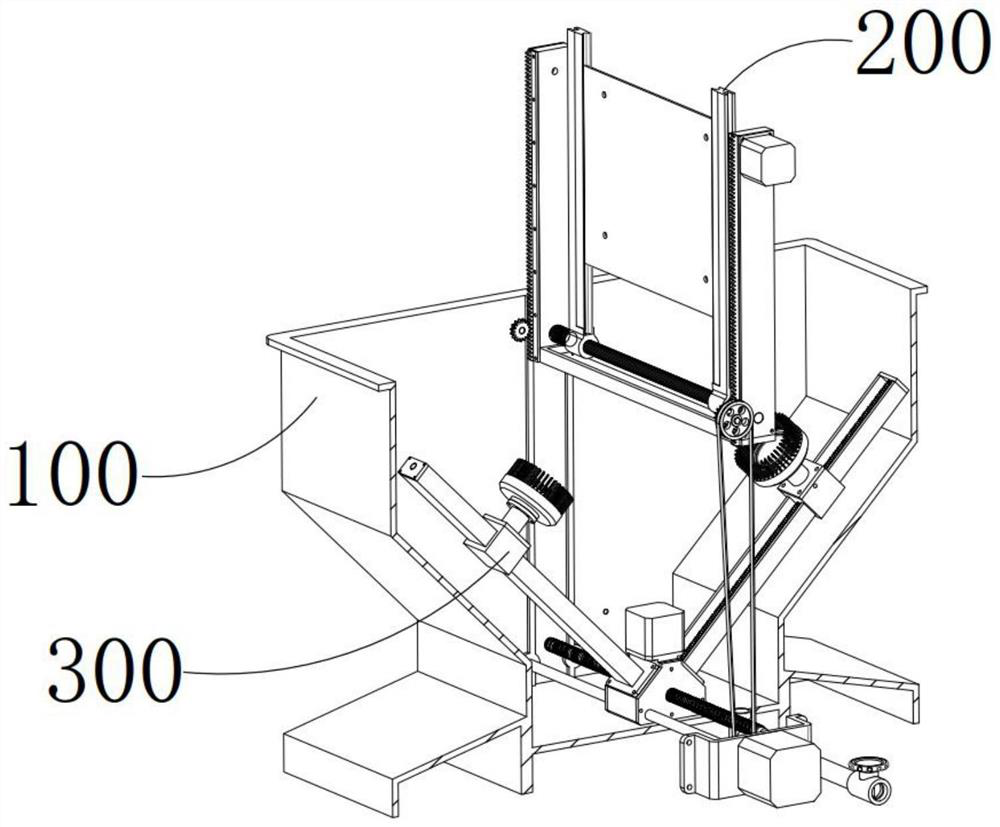

[0050] The flip type ultrasonic cleaning method of PCB printed circuit board, its steps are:

[0051] (1) Clamping stage;

[0052] S1: Place the circuit board on the clamping end of the clamping mechanism 200, the clamping mechanism 200 starts to operate and clamps the circuit board, and the clamped circuit board is in a vertical state;

[0053] The clamping mechanism 200 includes a lifting drive member 210 for driving it to move up and down in the vertical direction, and a tilting drive member 220 for driving it to tilt to the left / right, and the clamping mechanism 200 is configured to be able to The floating state and the sinking state are switched to each other and the initial state is the floating state. The clamping mechanism 200 in the floating state is located at the opening of the water tank 100, and the clamping mechanism 200 in the sinking state is located in the water tank 100 and submerged below the water surface. The driving member 210 can drive the clamping mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com