Heated inlet of a crankcase ventilation system

A crankcase ventilation, crankcase technology, applied in the crankcase field, can solve problems such as inability to obtain efficiency, not properly solved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Both the foregoing general description and the following detailed description are exemplary and explanatory only and do not limit the features that are claimed. As used herein, the terms "comprise", "comprising", "having", "including" or variations thereof are intended to cover a non-exclusive inclusion such that a process comprising a list of elements A method, article, or apparatus includes not only those elements, but may include other elements not expressly listed or inherent to such a process, method, article, or apparatus. Additionally, relative terms such as, for example, "about," "substantially," "substantially," and "approximately" are used to indicate a possible variation of ±10% of the stated value.

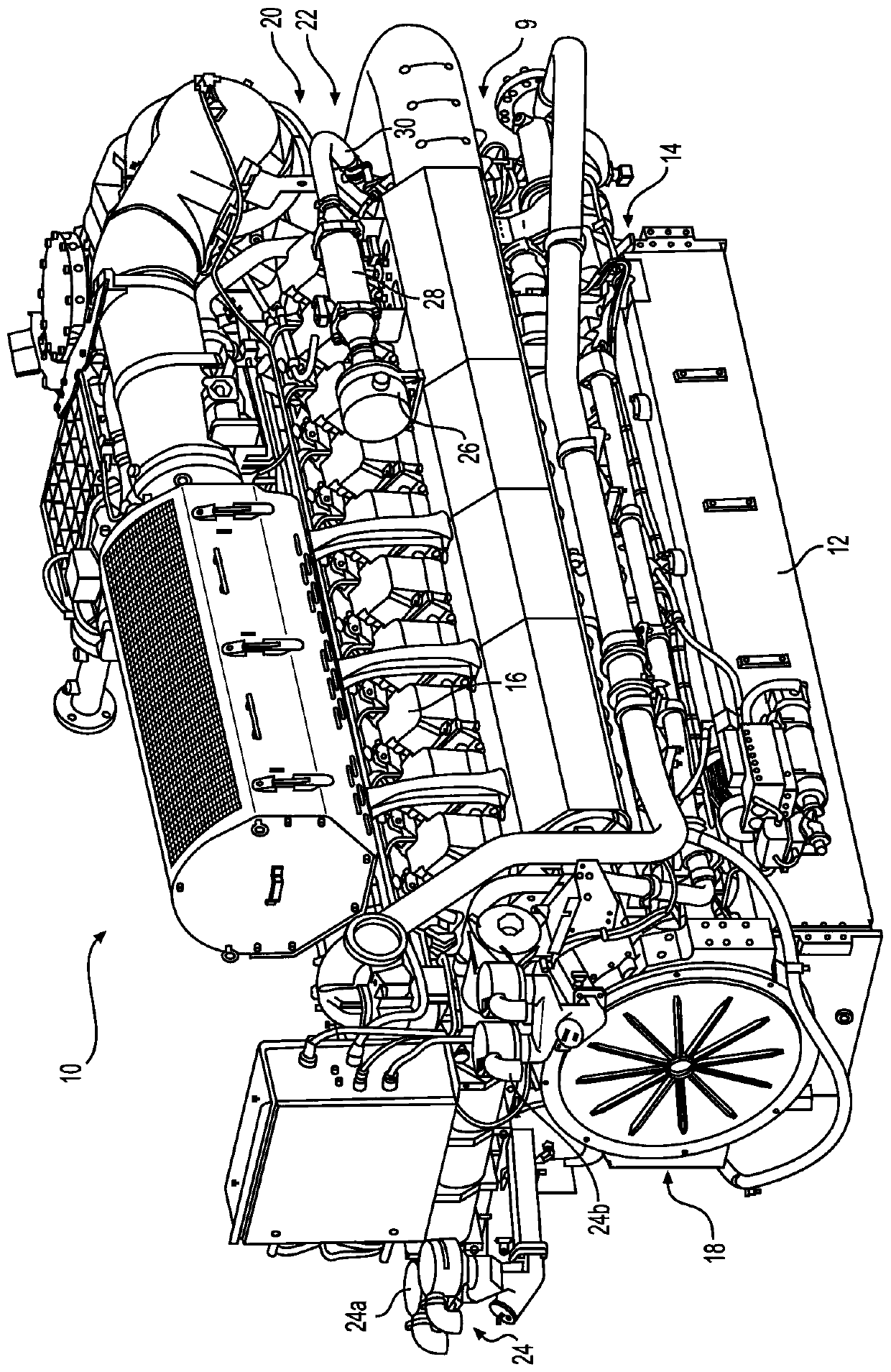

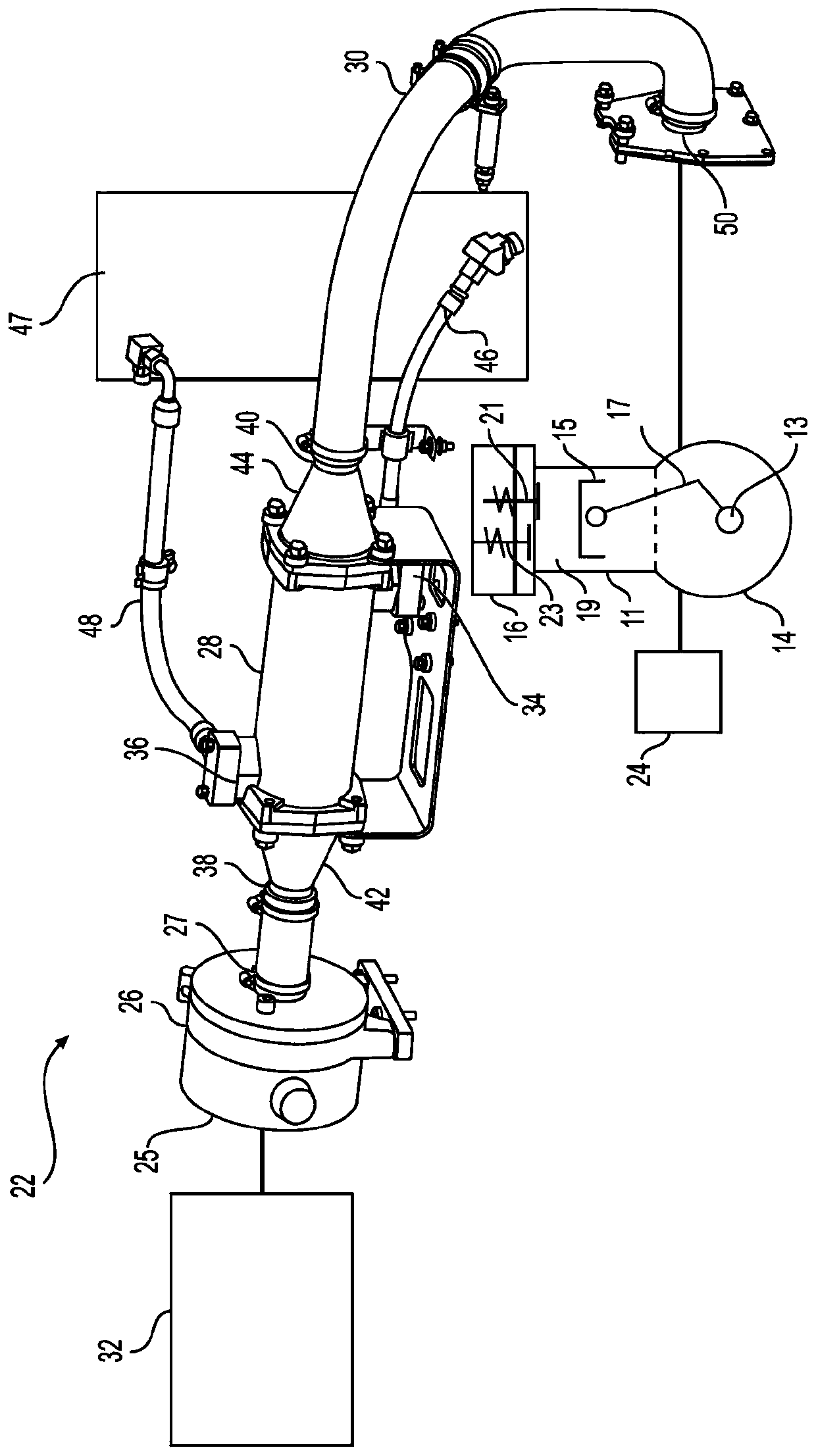

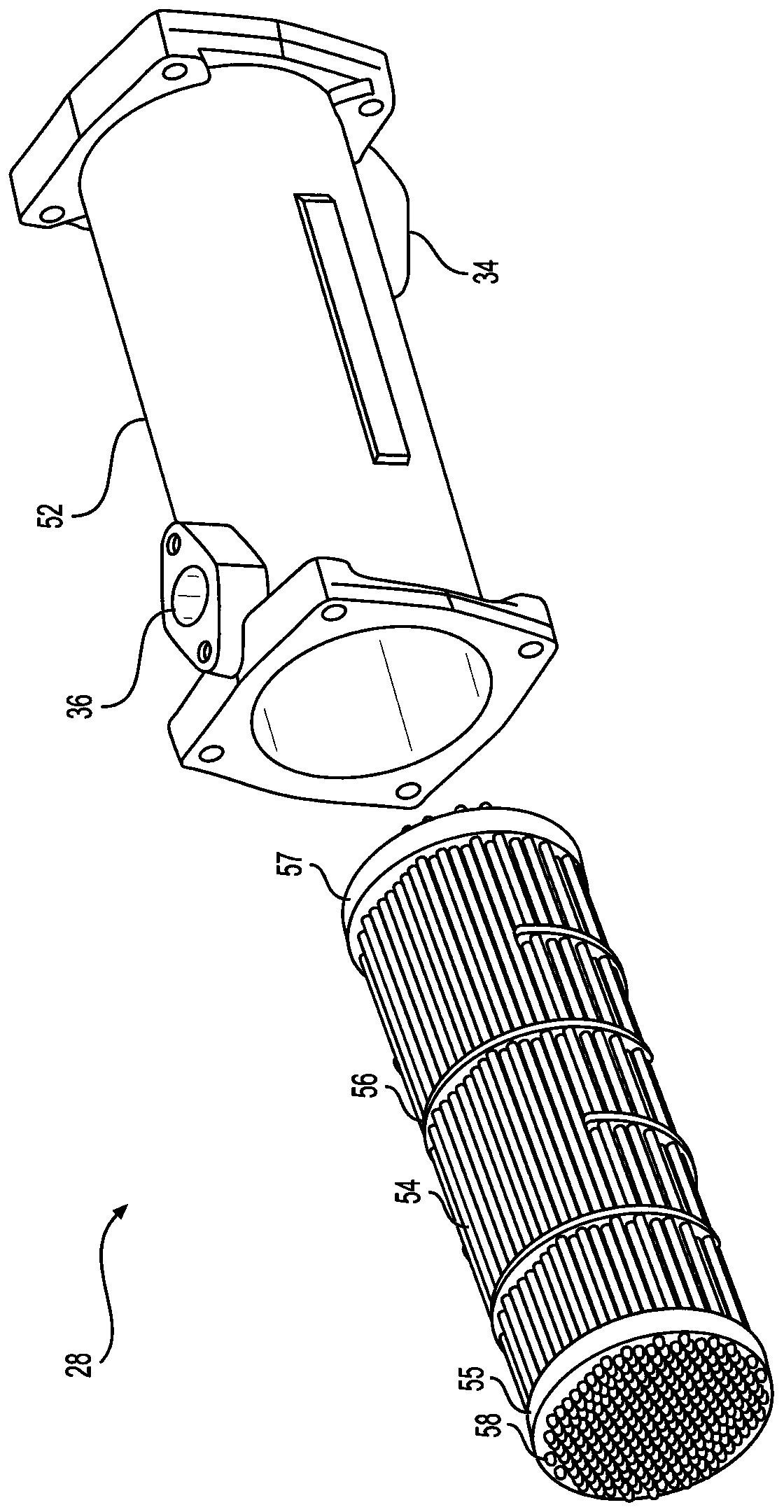

[0014] figure 1 is a perspective view of an internal combustion engine 10 having an exemplary crankcase ventilation system 20 according to aspects of the present disclosure. Engine 10 may be a stationary engine. As used herein, a "stationary engine" may be an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com