Direct-injection type concave cavity swirl nozzle

A swirl nozzle and concave cavity technology, applied in the field of direct-shot concave cavity swirl nozzles, can solve the problems of total pressure loss, nozzle blockage, affecting the stability and reliability of the engine combustion chamber, etc., to improve fuel atomization quality, The effect of reducing fuel distribution and shortening fuel atomization distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing:

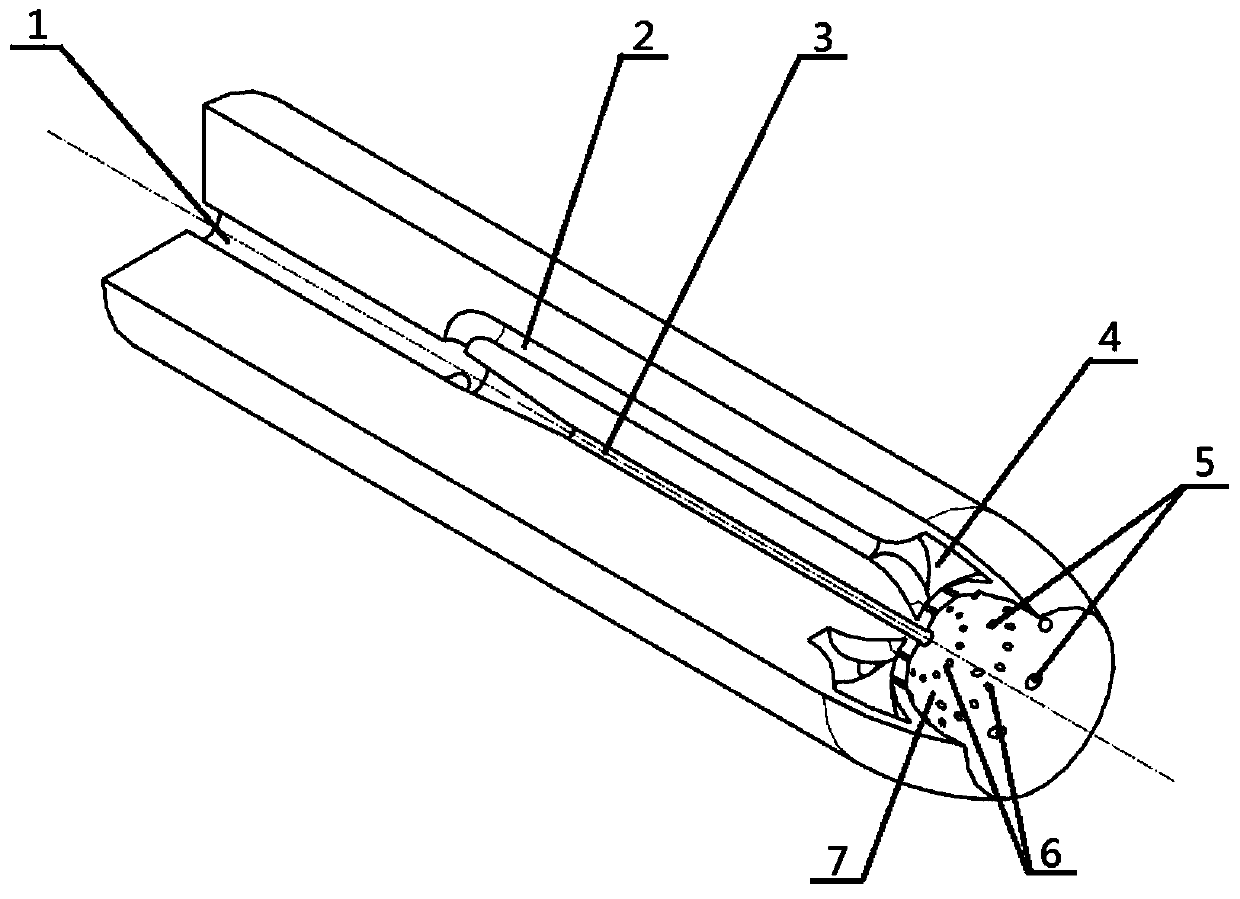

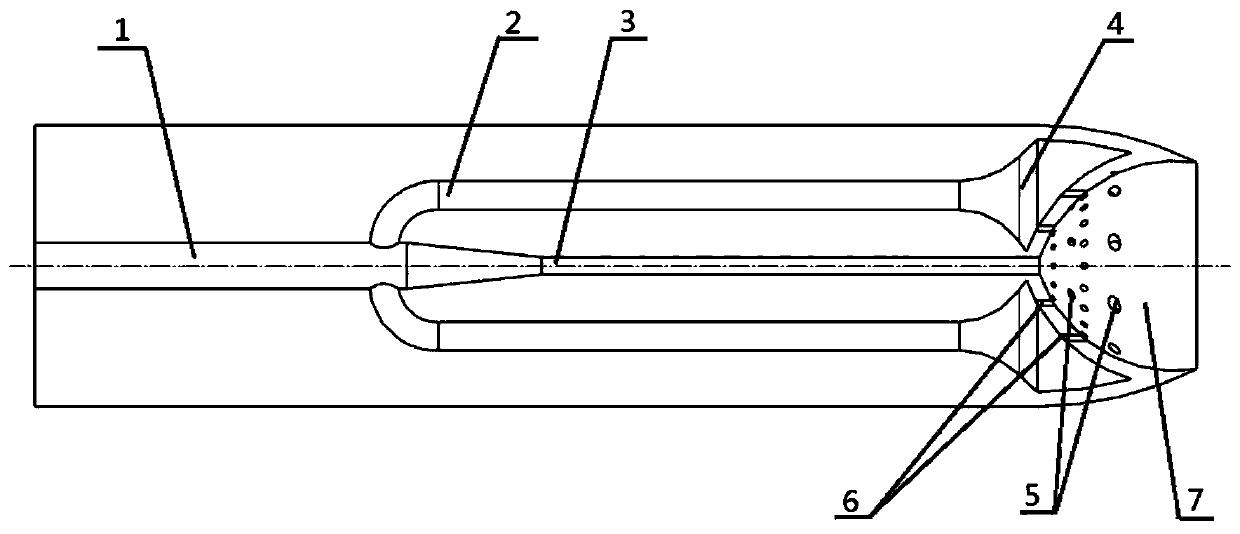

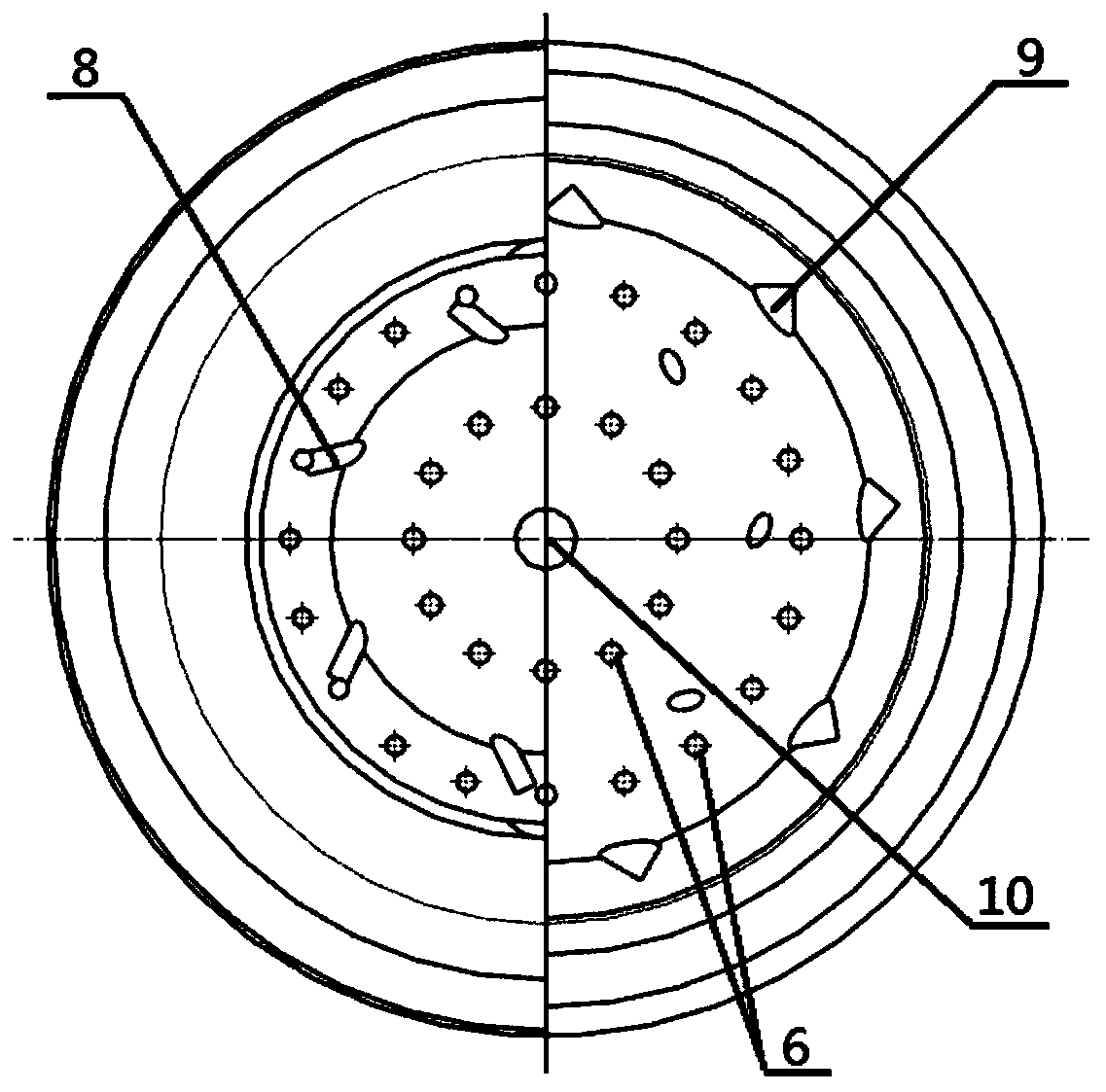

[0021] combine figure 1 , figure 2 , image 3 , the invention provides a technical proposal of a direct-injected concave cavity swirl nozzle. figure 1 It is a schematic diagram of the overall structure of the straight-shot concave cavity swirl nozzle, figure 2 It is a cross-sectional view of the central axis of the direct-injected concave swirl nozzle, image 3 It is a cross-sectional view of the radial oil injection hole on the head of the direct-injection concave swirl nozzle.

[0022] Specific process: the fuel enters the nozzle through the oil inlet hole (1), and is divided into a side oil delivery pipe (2) and a central oil delivery pipe (3) at 1 / 3 of the total length. ) is sprayed out, and the side fuel pipe (2) sends fuel into the annular cavity (4) to supply fuel to the multi-stage fuel injection holes, and the fuel sprayed from the radial fuel injection holes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com