Gripping unit and component as well as releasable connection of both

A component, clamping technology, applied in the field of releasable connection, which can solve the problems of error-prone, economically unattractive, high cost of manual assembly, to achieve the effect of ensuring manufacturability and short production duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

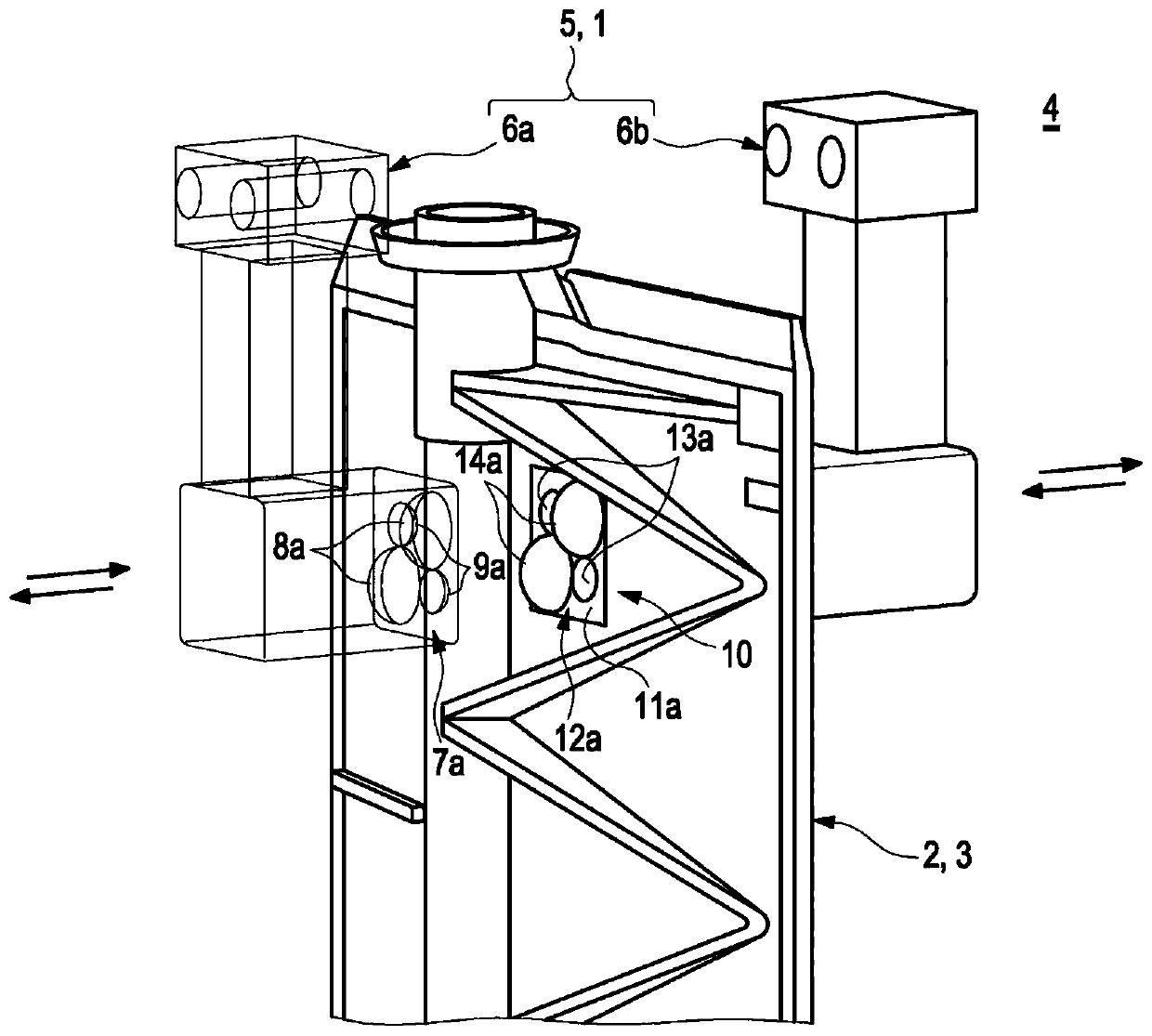

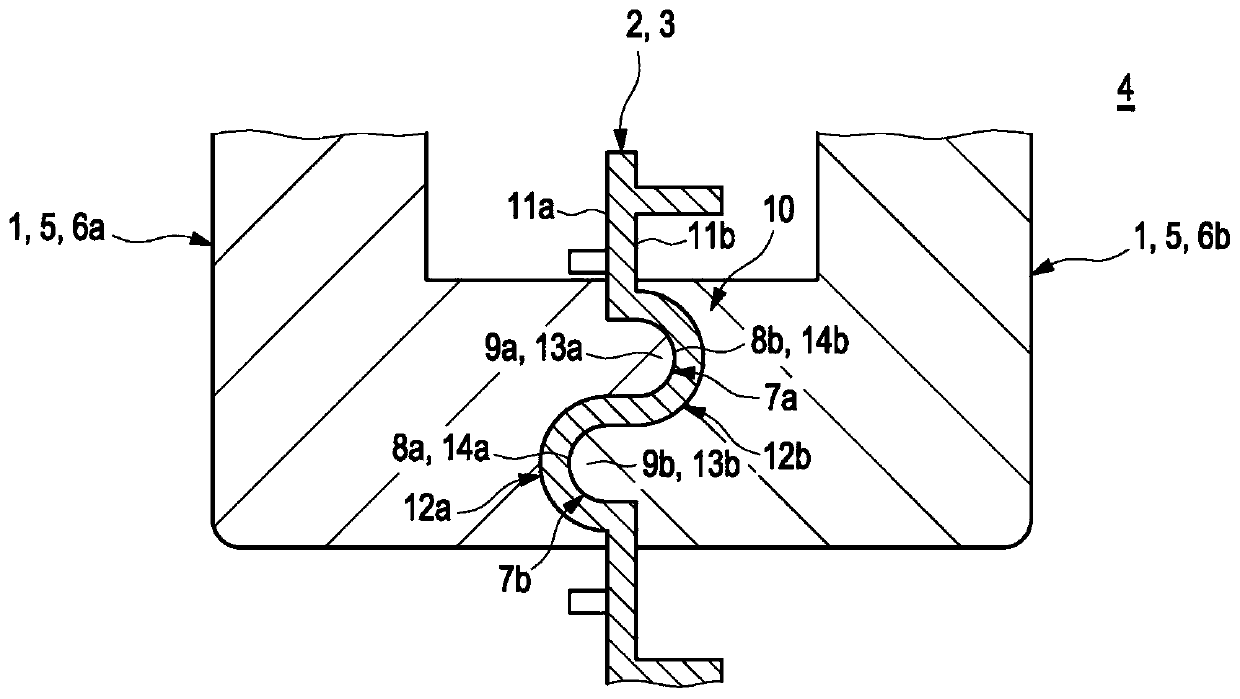

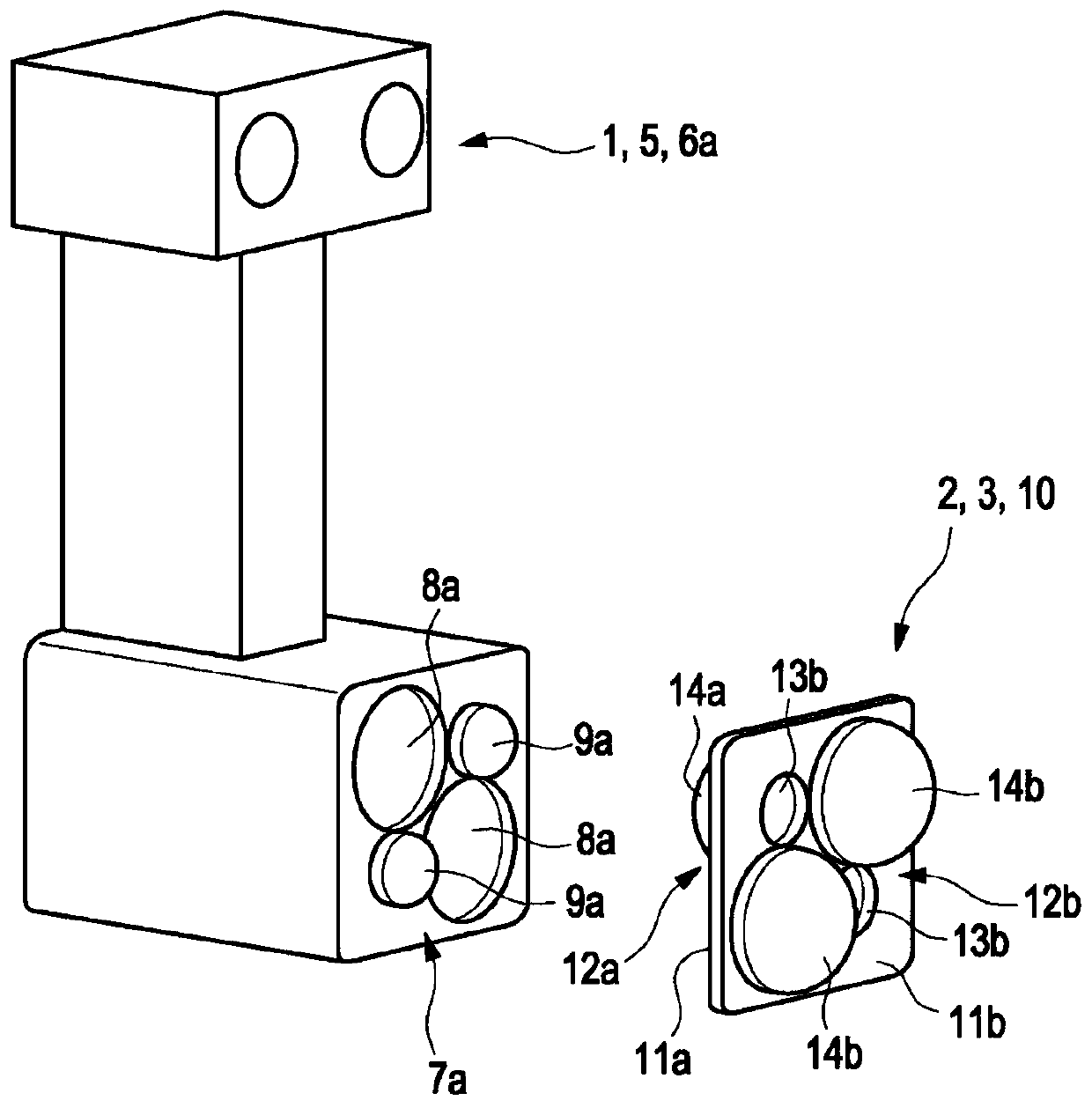

[0024] figure 1 A view of a clamping unit 1 according to the invention and an assembly 2 according to the invention is shown. In the exemplary embodiment, component 2 is a valve 3 for controlling air flow. Between the clamping unit 1 and the component 2 a connection 4 can be established and released. figure 1 Connection 4 is released. figure 2 A cross-sectional view of the clamping unit 1 and assembly 2 is shown in which the connection 4 has been established. refer to figure 1 and figure 2 , the clamping unit 1 comprises an assembly clamp 5 having a first clamping finger 6a and a second clamping finger 6b. exist figure 1 The middle part shows the clamping fingers 6a transparently. Such as figure 1 As indicated by the arrows in , the clamping fingers 6a and 6b are movable axially relative to each other into a clamping position and axially away from each other into a release position. Such as figure 1 As shown, the release position of the clamping fingers 6a and 6b cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com