Pop-up winding device

A wire winding device and a pop-up technology, applied in the field of the pop-up wire winding device, can solve the problems of loose and deformed wire coils, difficult transportation, and increased labor intensity of workers, so as to reduce labor intensity, fall off easily, and fall off easily and conveniently. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

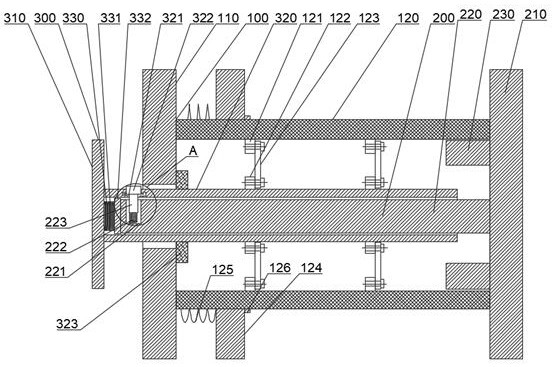

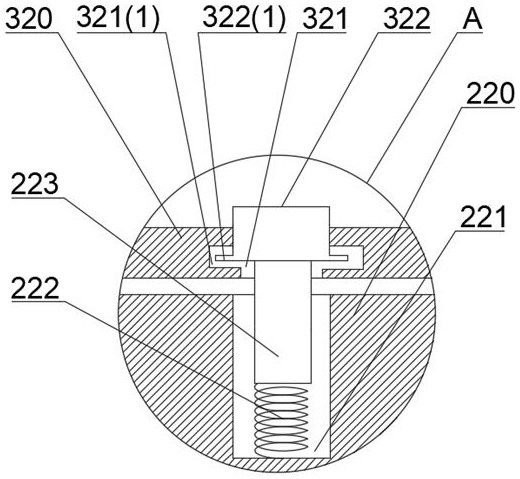

[0017] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments. Such as figure 1 As shown, a pop-up type winding device includes an outer core 100, an inner core 200 and a rotating shaft 300. The outer core 100 includes a first side plate 110 and a coil fixed on the first side plate. Wire barrel 120, the inner barrel core 200 includes a second side plate 210, a central shaft 220 and a support plate 230 fixed on the second side plate, and the central shaft 220 and the support plate are placed on the bobbin In 120 , the support plate 230 is cylindrical, and the outer wall of the support plate 230 is attached to the inner wall of the reel 120 to support the reel 120 . The second side plate 210 is located at an end of the reel 120 away from the first side plate 110 ;

[0018] The rotating shaft 300 includes a rotating handle 310 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com