Method and device for determining contact condition of circular cutting edge tool based on cutting force

A technology to determine the method and cutting force, which is applied in the direction of manufacturing tools, metal processing machinery parts, measuring/indicating equipment, etc., and can solve problems such as the inability to establish normal stress models and research problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The method for determining the contact condition of the circular cutting edge tool based on the cutting force involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0100]

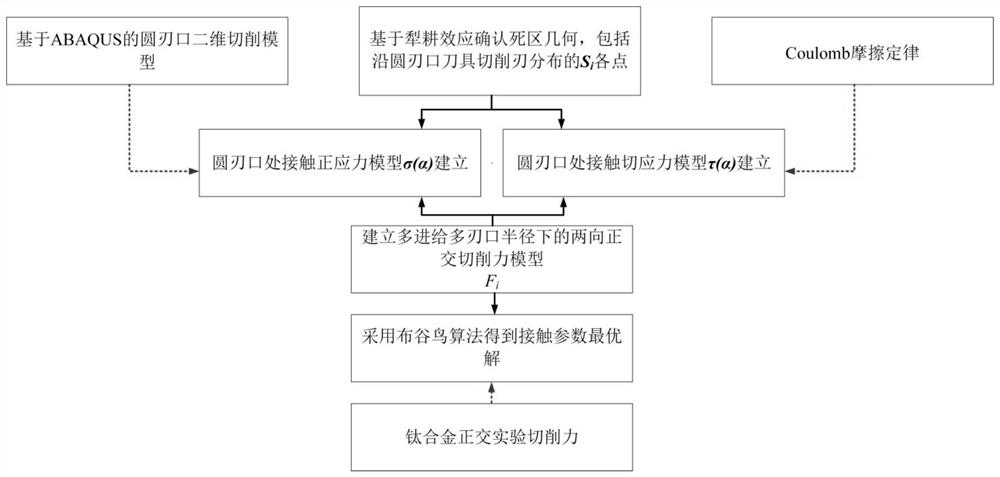

[0101] Such as figure 1 As shown, the method for determining the contact condition of the circular edge tool based on the cutting force provided in this embodiment includes the following steps:

[0102] Step 1. Establish a geometric model of the dead zone in the cutting process of the circular cutting edge tool, and describe the contact behavior and contact nodes at the circular cutting edge based on material deformation;

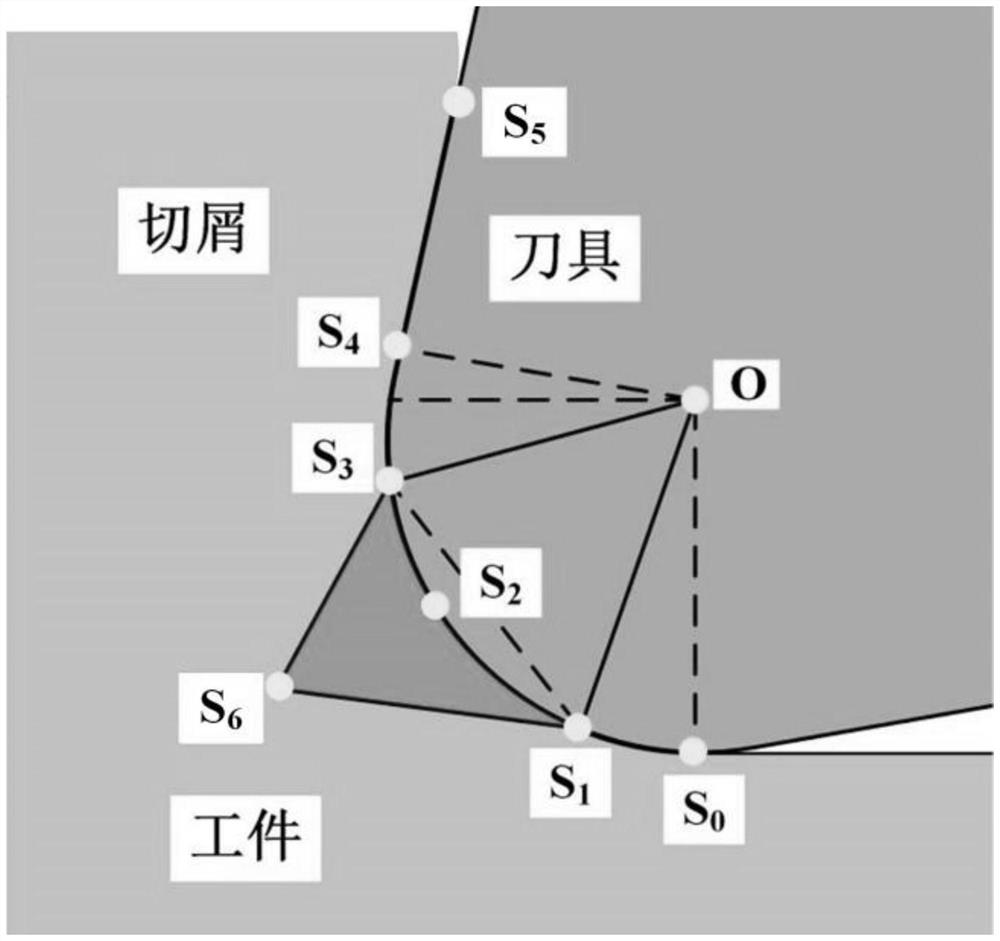

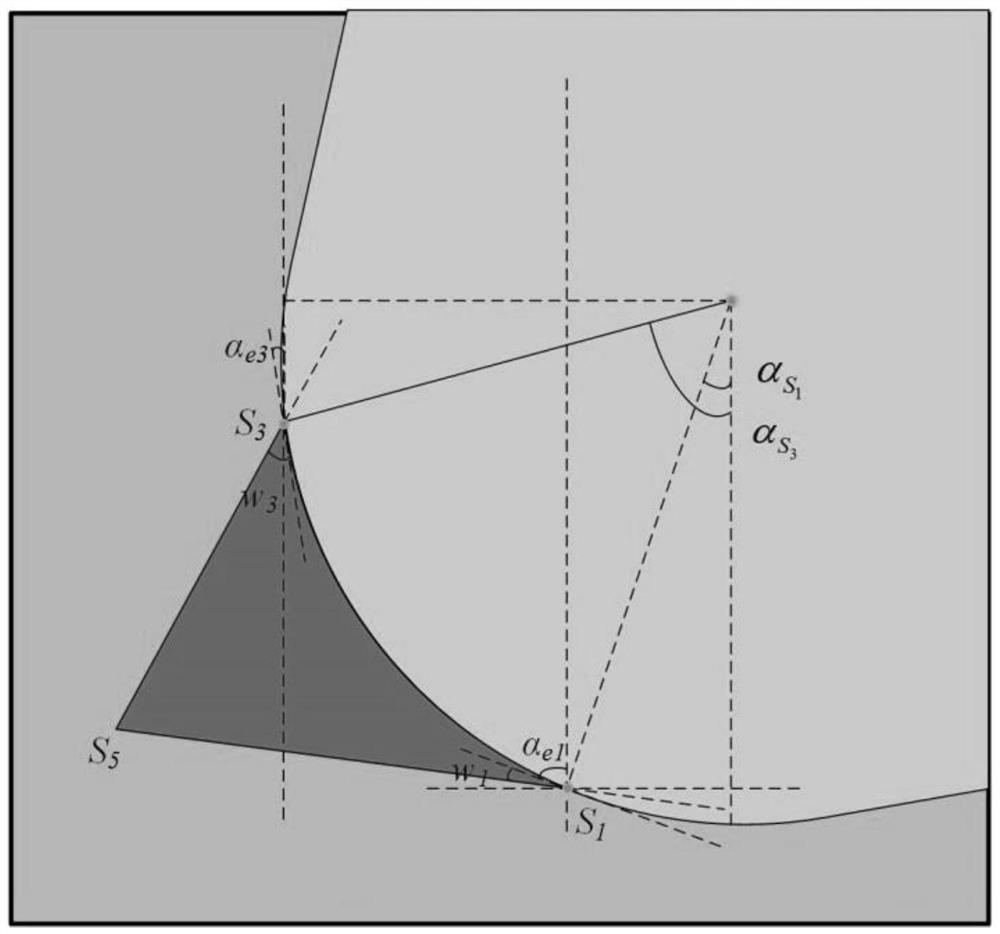

[0103] Step 1-1. In the cutting process of the circular edge tool, describe the complete plowing process, and establish a dead zone geometric model; during the metal cutting process, the relative speed between the part at the circular edge of the tool and the tool is 0 The workpiece material is called the dead zone st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com