Swing arm type obstacle crossing chassis

A swing arm type and chassis technology, applied in elastic suspension, vehicle parts, transportation and packaging, etc., can solve problems such as untimely adjustment of the center of gravity, easy tipping, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The implementation of the present invention will be described in further detail below in conjunction with accompanying drawing:

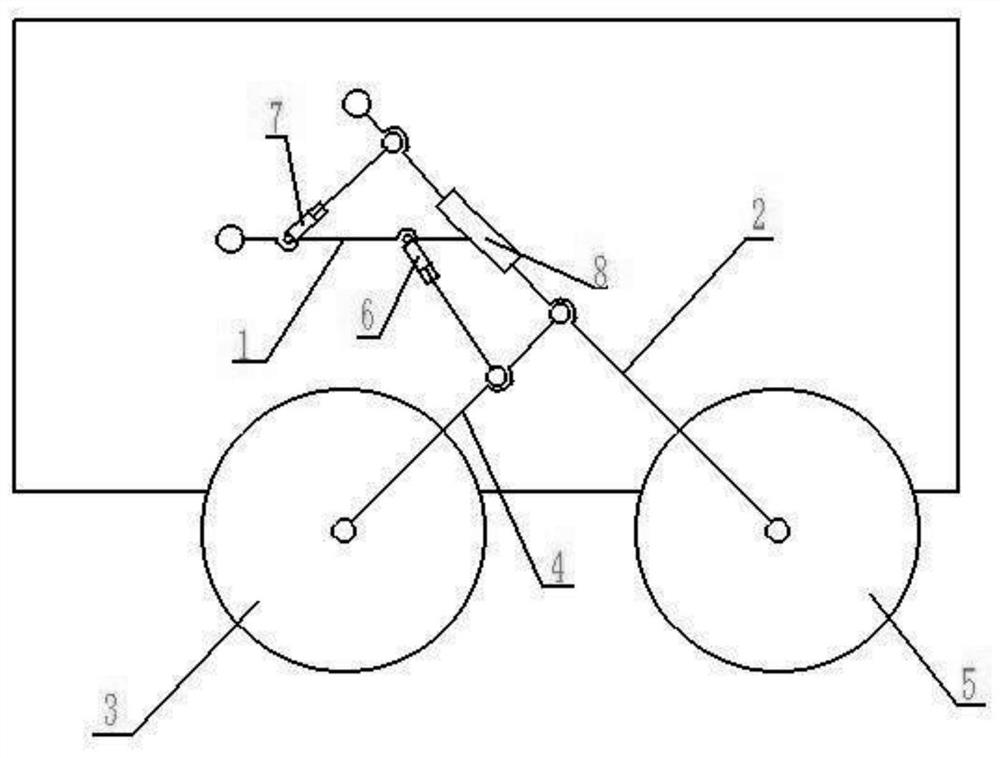

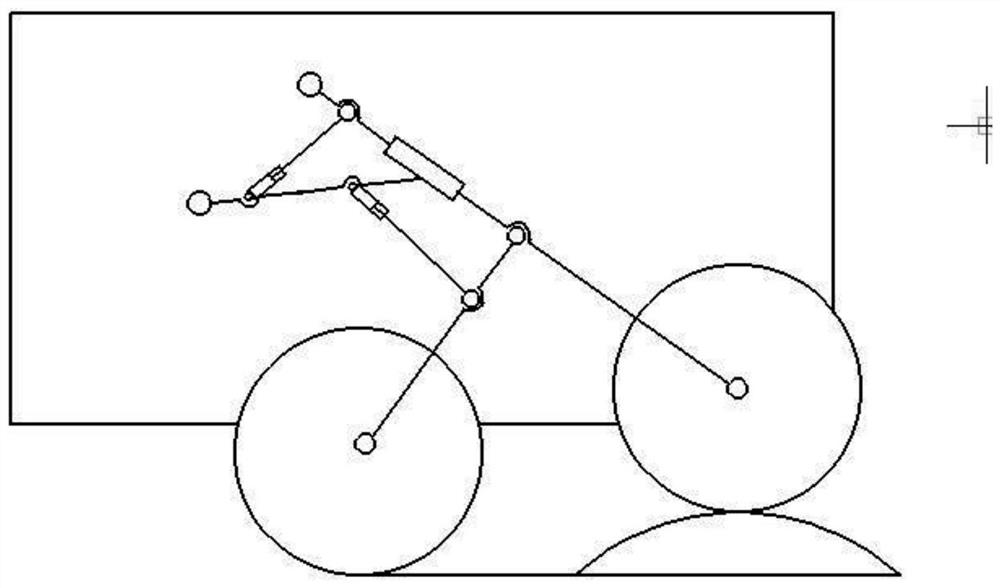

[0008] The lift-type special-shaped chain grass-separating mechanism of the present invention is characterized in that the swing-arm type obstacle-climbing chassis includes three parts: a vehicle body, a swing-arm drive mechanism, and front and rear wheels.

[0009] The swing arm type driving mechanism comprises a main driving arm, one and two auxiliary driving arms, one and two driving hydraulic cylinders, and an adjustment slide block.

[0010] The control of the swing arm type obstacle driving mechanism mainly depends on the driving hydraulic cylinder to push the planar link mechanism to move. The middle position is connected with the main driving arm 1 by adjusting the slider, and the main driving arm is respectively connected with the driving hydraulic cylinders 1 and 2, and the hydraulic rod of the driving hydraulic cylinder 1 can be st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com