An alkaline silane-doped borate water-based environmental rust inhibitor for rebar surface treatment

A technology of surface treatment and boric acid ester, which is applied in the direction of lubricating composition and petroleum industry, can solve the problems of no corrosion resistance of screw steel, high production cost, complicated process, etc., and achieve improved antirust performance, convenient use and maintenance, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below, the applicant will describe in detail the technical solutions and technical effects of the present invention with reference to specific embodiments. It should be understood that the following embodiments are only examples, and the present invention is not limited to these embodiments.

[0046] The present invention relates to an alkaline silane-doped borate water-based environmentally friendly rust inhibitor for the surface treatment of rebar, and its raw material composition in weight percentage is as follows: nano-level modified alkaline silica sol 1% to 50% , 0.1% to 5% of borate ester, 0.01% to 1% of metal complexing agent, 0.01% to 0.5% of bactericide, and water balance.

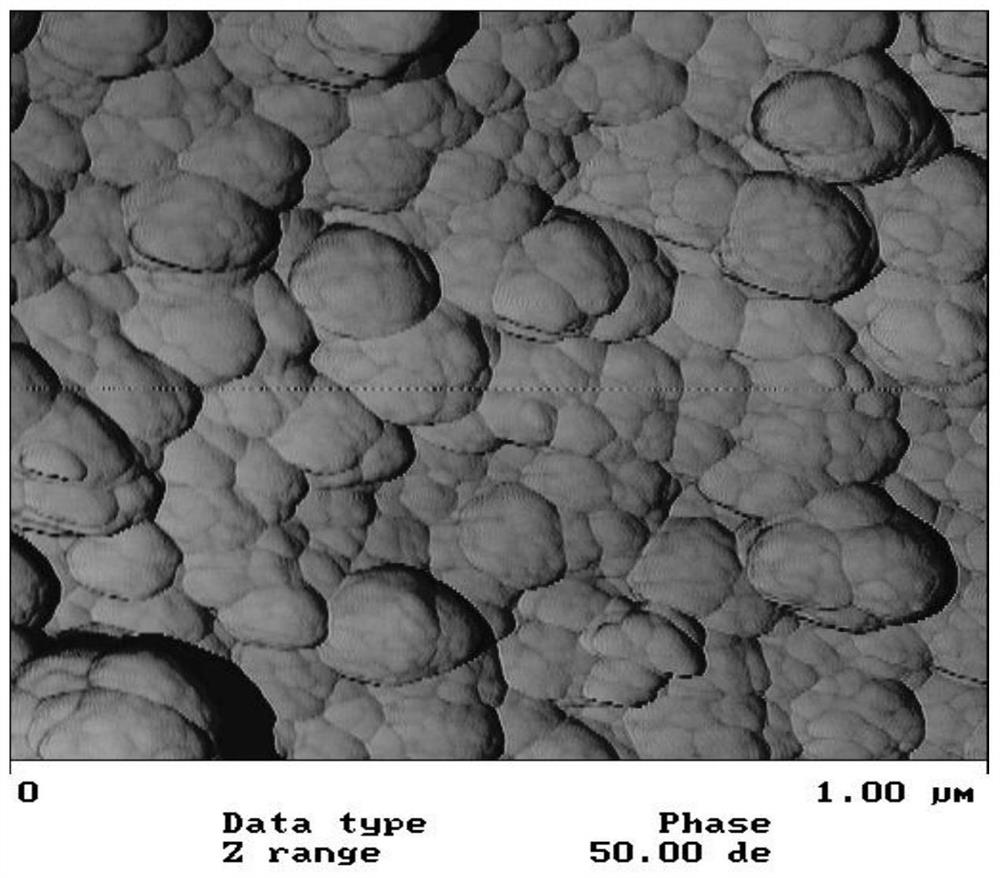

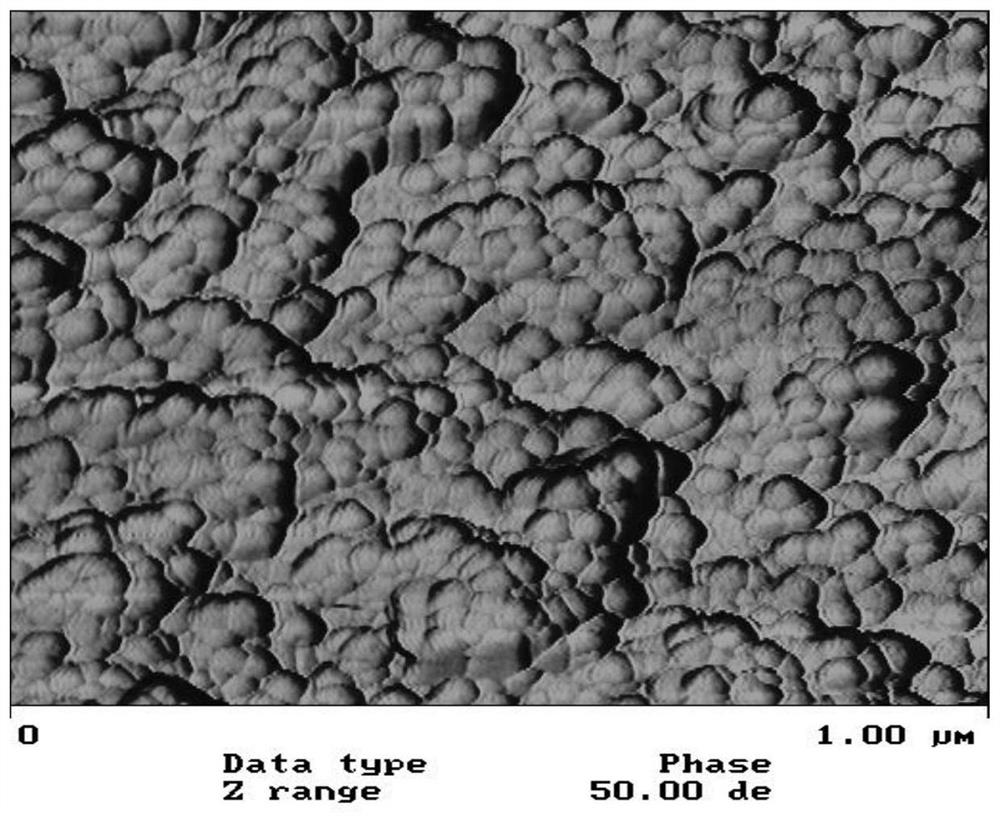

[0047] Among them, the nano-scale modified alkaline silica sol is the main film-forming substance, and the borate is the repair agent and corrosion inhibitor of the film layer. The combination of the modified alkaline silica sol and the borate can form a dense organic-inorganic combination...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com