A preparation method of polyacrylate/benzotriazole@zinc oxide microcapsule composite anticorrosion coating

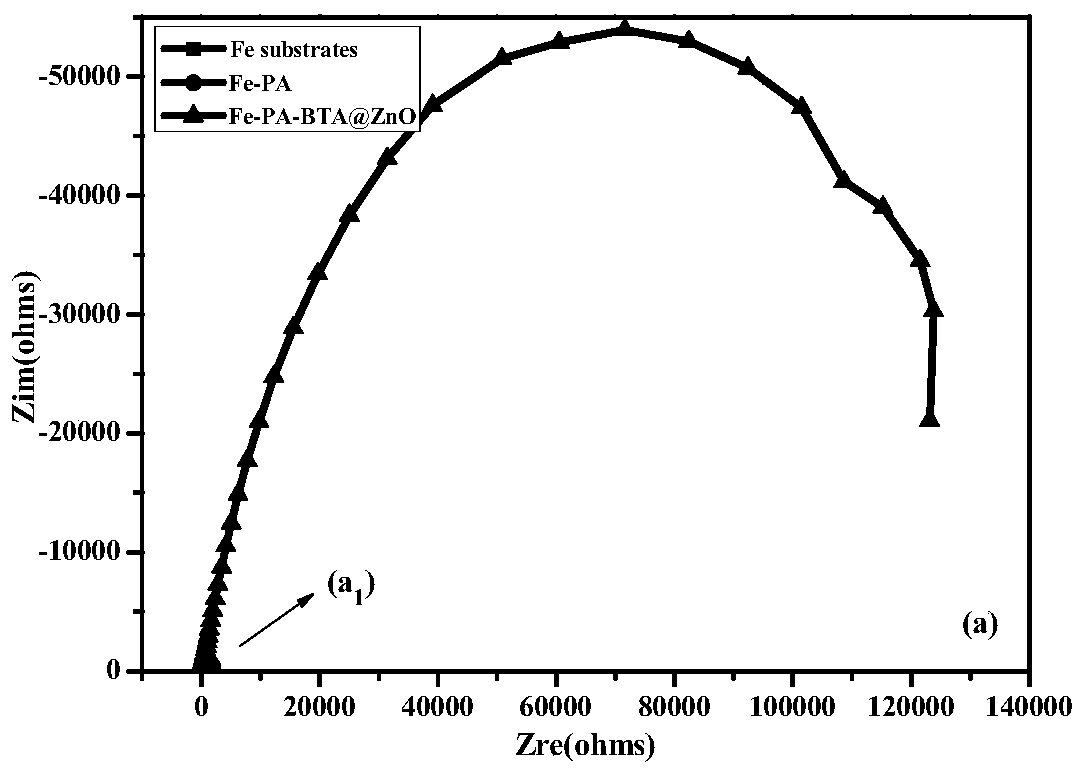

A technology of benzotriazole and polyacrylate, which is applied in the direction of anti-corrosion coatings and coatings, can solve the problems of limited anti-corrosion performance of polyacrylate, difficulty in achieving long-term and durable anti-corrosion, and restricting the application of polyacrylate, so as to benefit Long-term anti-corrosion, improve water resistance and adhesion, and improve the anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

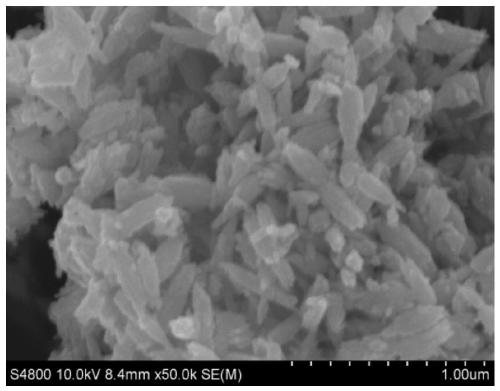

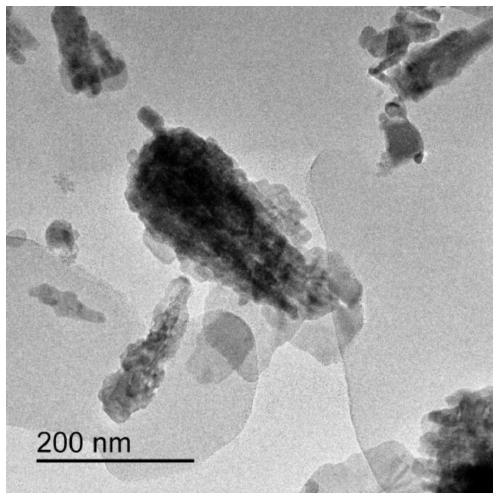

[0044]Dissolve 0.6g of benzotriazole in 5.2g of chloroform to form an oil phase, then add the oil phase and 0.25g of sodium lauryl sulfate into a three-necked flask filled with 30.0g of deionized water, and stir at a constant temperature of 55°C After 2 hours, a stable oil-in-water emulsion was formed. Then slowly add 16.8g of zinc acetate aqueous solution dropwise into the above emulsion, and continue to stir for 3h. Then, 15.66 g of aqueous sodium hydroxide solution was slowly added dropwise, and stirred for 1 h. Finally, put the mixed solution in a constant temperature water bath at 85°C and let it age for 5 hours. The white precipitate in the lower layer was washed with deionized water and dried in an oven at 75°C to obtain benzotriazole@zinc oxide microcapsules. Among them, the mass ratio of zinc acetate to deionized water in the zinc acetate aqueous solution is 1.8:15; the mass ratio of sodium hydroxide to deionized water in the sodium hydroxide aqueous solution is 0.66...

Embodiment 2

[0047] Dissolve 1.5 g of benzotriazole in 5.0 g of chloroform to form an oil phase, then add it and 0.5 g of sodium lauryl sulfate into a three-necked flask filled with 30.5 g of deionized water, and stir at a constant temperature of 55 ° C for 2.5 h, forming a stable oil-in-water emulsion. Then slowly add 21.0 g of zinc acetate aqueous solution dropwise into the above emulsion, and continue stirring for 3.5 h. Then, 17.5 g of sodium hydroxide aqueous solution was slowly added dropwise, and stirred for 1.5 h. Finally, put the mixed solution in a constant temperature water bath at 85°C and let it age for 5 hours. The white precipitate in the lower layer was washed with deionized water and dried in an oven at 75°C to obtain benzotriazole@zinc oxide microcapsules. Among them, the mass ratio of zinc acetate to deionized water in the zinc acetate aqueous solution is 1:20; the mass ratio of sodium hydroxide to deionized water in the sodium hydroxide aqueous solution is 2:15.5.

[...

Embodiment 3

[0050] Dissolve 1.2 g of benzotriazole in 5.1 g of chloroform to form an oil phase, then add it and 0.3 g of sodium lauryl sulfate into a three-necked flask filled with 30.2 g of deionized water, and stir at a constant temperature of 53 ° C for 2.3 h, forming a stable oil-in-water emulsion. Then slowly add 18.8g of zinc acetate aqueous solution dropwise into the above emulsion, and continue to stir for 3.1h. Then, 16.5 g of aqueous sodium hydroxide solution was slowly added dropwise, and stirred for 1.3 h. Finally, the mixed solution was placed in a constant temperature water bath at 83°C and aged for 6 hours, the white precipitate in the lower layer was washed with deionized water, and dried in an oven at 73°C to obtain benzotriazole@zinc oxide microcapsules. Among them, the mass ratio of zinc acetate to deionized water in the zinc acetate aqueous solution is 1:17.8; the mass ratio of sodium hydroxide to deionized water in the sodium hydroxide aqueous solution is 1.5:15.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com