Jacking device and AGV

A technology of a jacking device and a jacking plate, applied in the direction of the lifting device, etc., can solve the problems of unfavorable matching AGV trolley use, self-weight of the jacking mechanism, damage to the jacking plate, etc. The effect of lifting requirements and simple product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

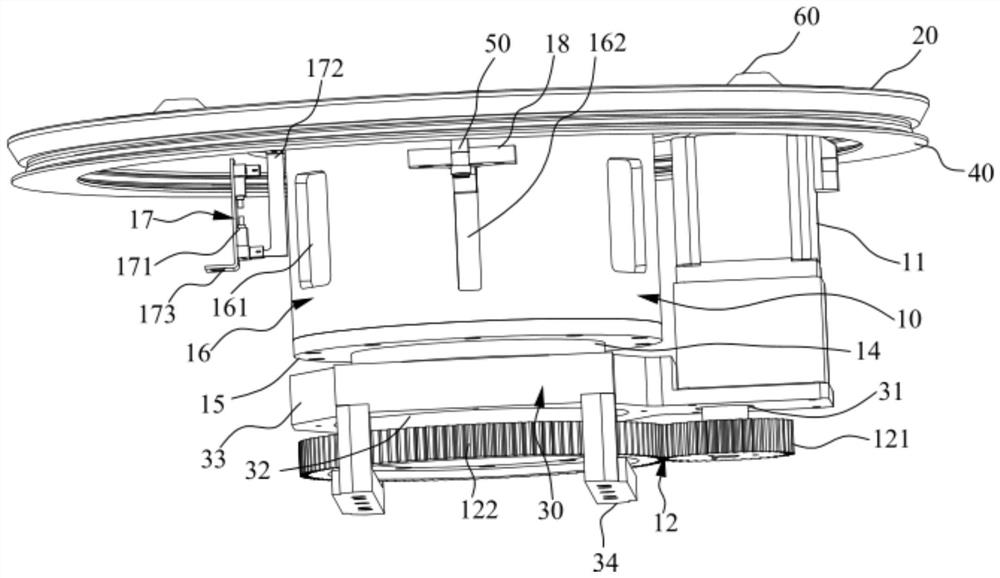

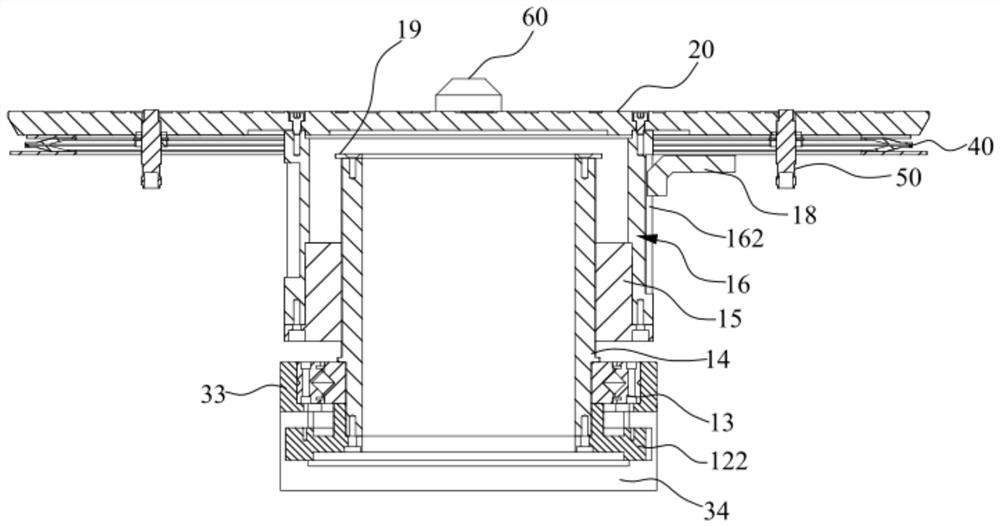

[0033] like figure 1 , figure 2 As shown, the embodiment of the present invention provides a jacking device that can be used on a latent AGV trolley. The jacking device includes a lifting mechanism 10, a lifting plate 20 and a lifting bracket 30; Inside the frame of the AGV trolley. The lifting mechanism 10 includes a driving member 11, a transmission assembly 12, a bearing, a screw mandrel 14, a nut 15 and a support member 16; the driving member 11 is used to drive the transmission assembly 12 to provide power for the lifting mechanism 10, and the embodiment of the present invention uses a motor to drive , high driving precision, convenient speed regulation, simple and reliable structure. In the embodiment of the present invention, the transmission assembly 12 includes a driving gear 121 and a follower gear 122, and adopts a transmission form of gear meshing, which has a compact structure and stable operation. Of course, in other embodiments, other forms of transmission ...

Embodiment 2

[0042] This embodiment provides an AGV trolley, which includes a vehicle frame and the jacking device in Embodiment 1, and the lifting bracket 30 of the jacking device is fixedly connected to the vehicle frame. At the same time, the sensor 171 of the jacking device is fixed on the vehicle frame, one end of the anti-rotation block 18 is fixed on the vehicle frame, and the other end is slidably matched with the second slot 162 . The jacking device uses a large-diameter hollow screw for jacking, which can stably carry a large weight, avoiding the problem of large torque when the center of gravity of the load is not centered, and greatly increasing the jacking weight while reducing its own weight range, the product structure is simple, and the installation size is small, which can meet the requirements for the jacking of AGV trolleys.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com