Special tool for adjusting cold-rolled vertical loop car track and use method thereof

A vertical looper and special tool technology, which is applied in the direction of manufacturing tools, bending workpieces, metal rolling, etc., can solve the problems of inconvenient construction and easy occurrence of dangers for personnel, and achieve the effect of reducing personnel input and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

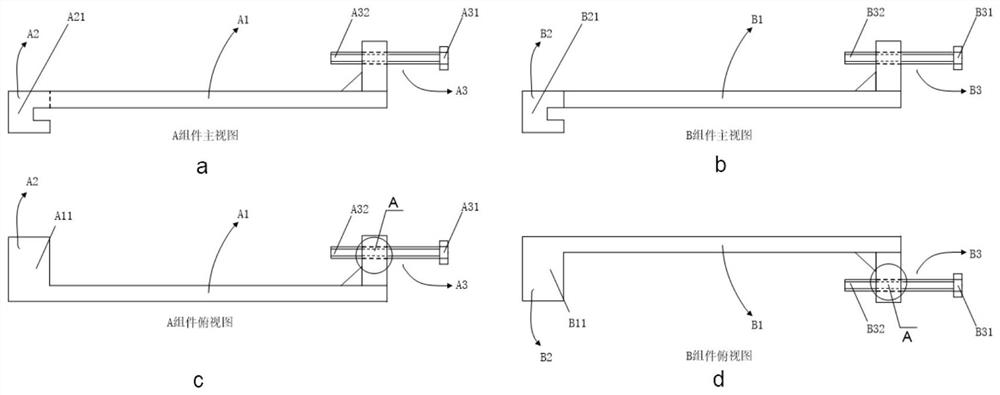

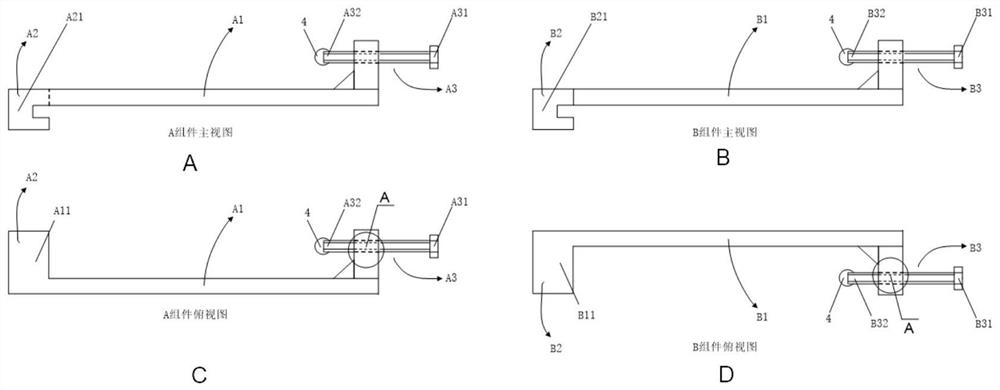

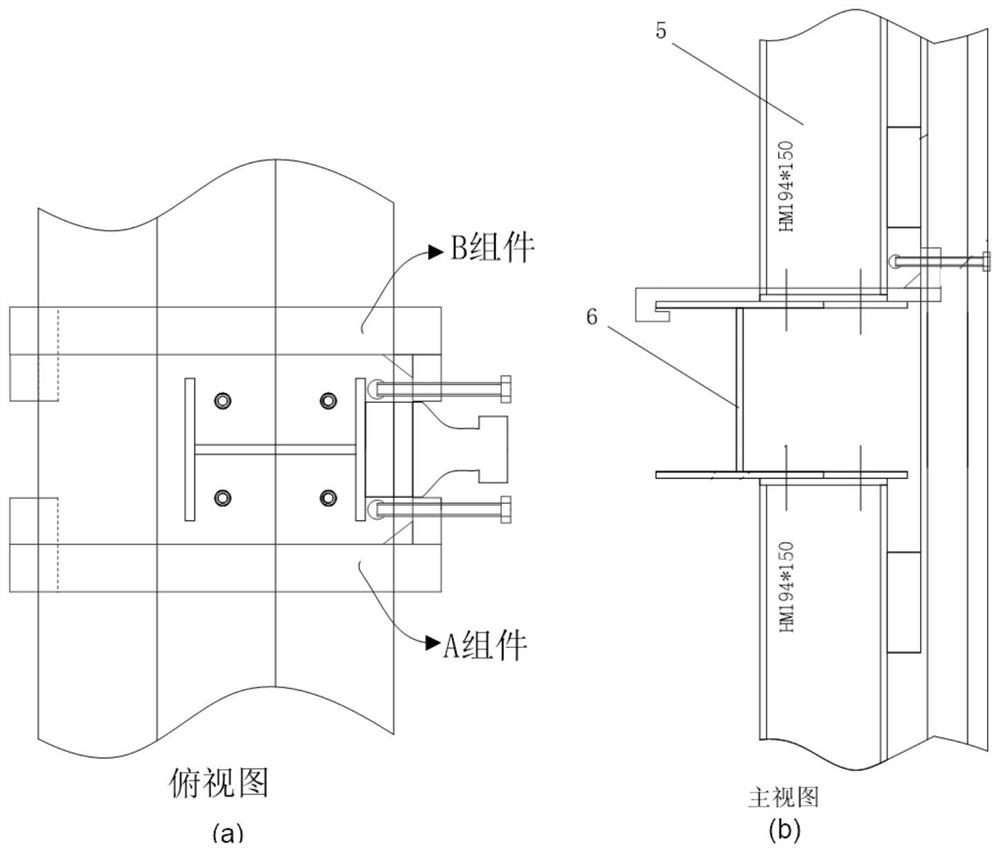

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0024] Such as Figure 1-4 As shown, the present invention provides a special tool for adjusting the track of the cold-rolled vertical looper, including A component and B component, which are respectively stuck on the left and right sides of the fixed beam 6 of the steel structure frame of the looper, perpendicular to it Connect the left and right sides of vertical looper track beam 5 to adjust, until vertical looper track beam 5 returns normal position, and then vertical looper track returns normal position. Due to the vertical connection structure between the fixed beam 6 of the steel structure frame of the looper and the track beam 5 of the vertical looper, other parts are arranged at the position facing the track beam 5 of the vertical looper, which makes it inconvenient to align the center The posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com