A mandrel lifting mechanism

A hoisting and mandrel technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problem of low safety performance of the mandrel replacement operation, and achieve the effect of safe and reliable use, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

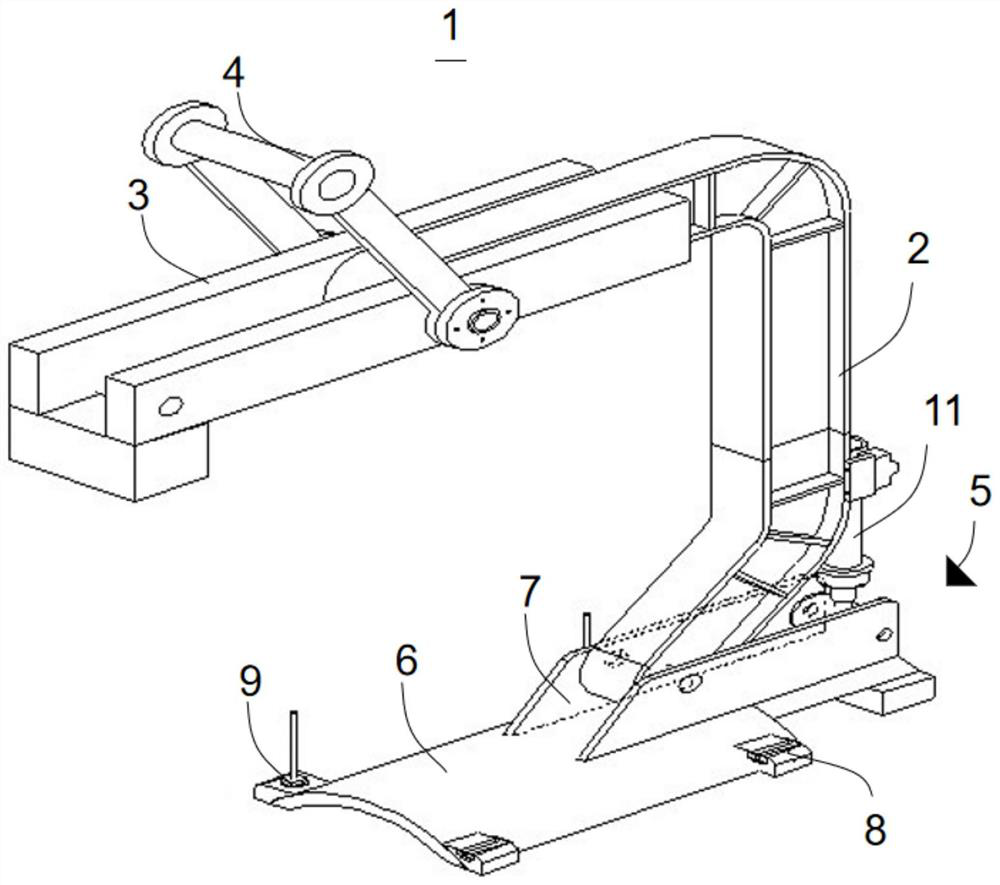

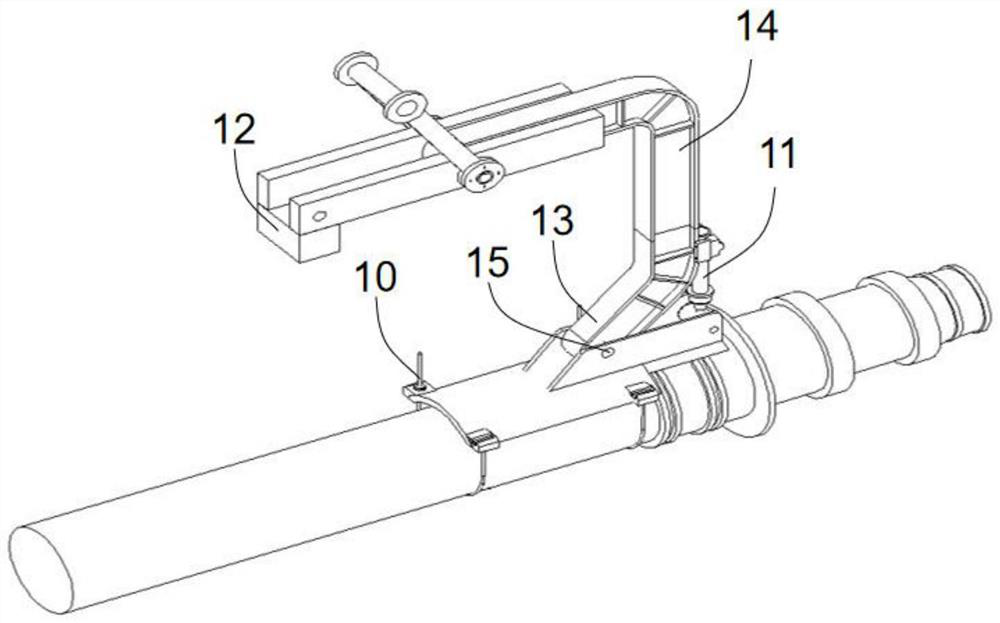

[0034] Please refer to figure 1 , with reference to figure 2 , the present application provides a mandrel hoisting mechanism 1, including a support frame 2, a connecting frame 3, a hoisting assembly 5 and a hydraulic cylinder 11, and the hoisting assembly 5 includes an arc-shaped limiting plate 6 and two positioning plates 7; wherein, the connecting frame One end of 3 is vertically connected to the top of the supporting frame 2; the bottom of the lifting lug 4 is hinged on the middle position of the connecting frame 3, and the device is hung on the crane hook through the lifting lug 4 during hoisting; at the same time, on the connecting frame 3 A counterweight 12 is fixedly installed on the bottom of the free end of the free end, which can make the whole device more stable; two positioning plates 7 are installed on the upper surface of the arc-shaped limiting plate 6 in parallel and at intervals, and the two are respectively connected with the arc-shaped limiting plate. The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap