Heat dissipation device

A technology of heat dissipation device and support frame, which is applied in the cooling/ventilation of substation/switchgear, details of substation/switch arrangement, electrical components, etc., and can solve the problems of poor cooling effect of cooling fans and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

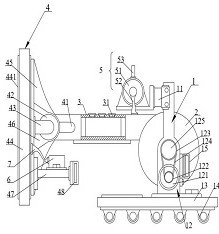

[0048] This embodiment provides a cooling device, such as figure 1 As shown, it includes a support frame 1 , a winding part 2 , a pipe body 3 , a first air extraction assembly 4 and a second air extraction assembly 5 . Wherein, the winding part 2 is rotatably arranged on the support frame 1; one end of the pipe body 3 is wound around the winding part 2, and the other end is a free end; the first air extraction assembly 4 is connected to the free end of the pipe body 3 for The gas around the power distribution cabinet is sucked into the pipe body 3; the second air extraction assembly 5 is arranged on the support frame 1, located on one side of the pipe body 3, can be connected to the pipe body 3, and is located downstream of the gas flow direction, for Vent gas to ambient. In this embodiment, the pipe body 3 is preferably a rubber hose, which is convenient for installation and has a good sealing effect.

[0049] The hot air inside and around the power distribution cabinet pas...

Embodiment 2

[0060] Parts in this embodiment that are the same as or corresponding to those in the first embodiment use the reference numerals that correspond to those in the first embodiment. For simplicity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is that the heat dissipation device also includes a driving mechanism, which is arranged on the support frame 1 and is used to drive the winding part 2 to rotate to retract the free end of the tube body 3 . The drive mechanism is provided to automatically retract and unwind the free end of the tube body 3, saving time and effort.

[0061] Specifically, the driving mechanism includes a motor 121, a driving gear 122, a driven gear 123 and a chain 124. The motor 121 is arranged on the support frame 1; the driving gear 122 is connected to the output end of the motor 121; On the support frame 1 , the driven gear 123 is sleeved on the rotating shaft 125 ; the chain 124 is wound around the driving gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com