Alloy classification method and system based on atomic configuration

A technology of atomic configuration and classification method, applied in the field of materials science, can solve the problems of incomplete statistics of polyhedron edges, non-uniform values, data inconsistency, etc., and achieve the effect of small side length, compatible side length, and complete statistics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

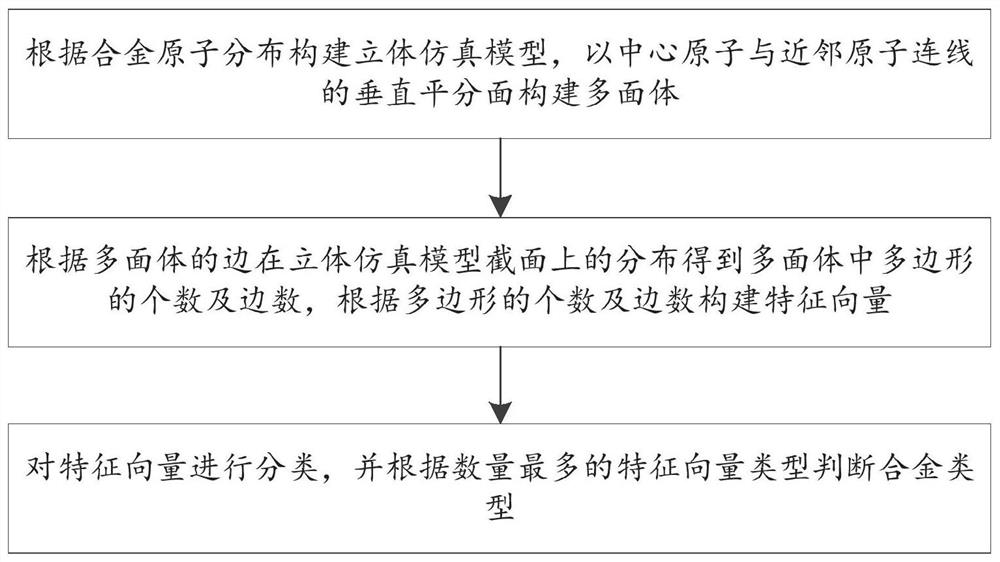

[0033] Such as figure 1 As shown, the present embodiment provides a method for classifying alloys based on atomic configuration, including:

[0034] S1: Construct a three-dimensional simulation model according to the distribution of alloy atoms, and construct a polyhedron with the vertical bisection plane connecting the central atom and the neighboring atoms;

[0035] S2: Obtain the number of polygons and the number of sides in the polyhedron according to the distribution of the sides of the polyhedron on the section of the three-dimensional simulation model, and construct a feature vector according to the number of polygons and the number of sides;

[0036] S3: Classify the eigenvectors, and judge the alloy type according to the type of eigenvectors with the largest number.

[0037] In this embodiment, the alloy structure contains atoms and polyhedrons surrounding atoms, and the polygons are identified and statistically assisted to analyze the type and performance of the all...

Embodiment 2

[0071] This embodiment provides an alloy classification system based on atomic configuration, including:

[0072] The simulation module is used to construct a three-dimensional simulation model according to the distribution of alloy atoms, and construct a polyhedron with the vertical bisection plane connecting the central atom and the neighboring atoms;

[0073] Statistical module, for obtaining the number of polygons and the number of sides in the polyhedron according to the distribution of the sides of the polyhedron on the section of the three-dimensional simulation model, and constructing a feature vector according to the number of polygons and the number of sides;

[0074] The judging module is used to classify the feature vectors, and judge the alloy type according to the largest number of feature vector types.

[0075] It should be noted here that the above-mentioned modules correspond to steps S1 to S3 in Embodiment 1, and the examples and application scenarios impleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com