Solid-wood fireproof door manufacturing method and solid-wood fireproof door

A manufacturing method and technology for fire doors, applied in the field of fire doors, can solve the problems of poor smoke prevention effect, insufficient closeness of fire doors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

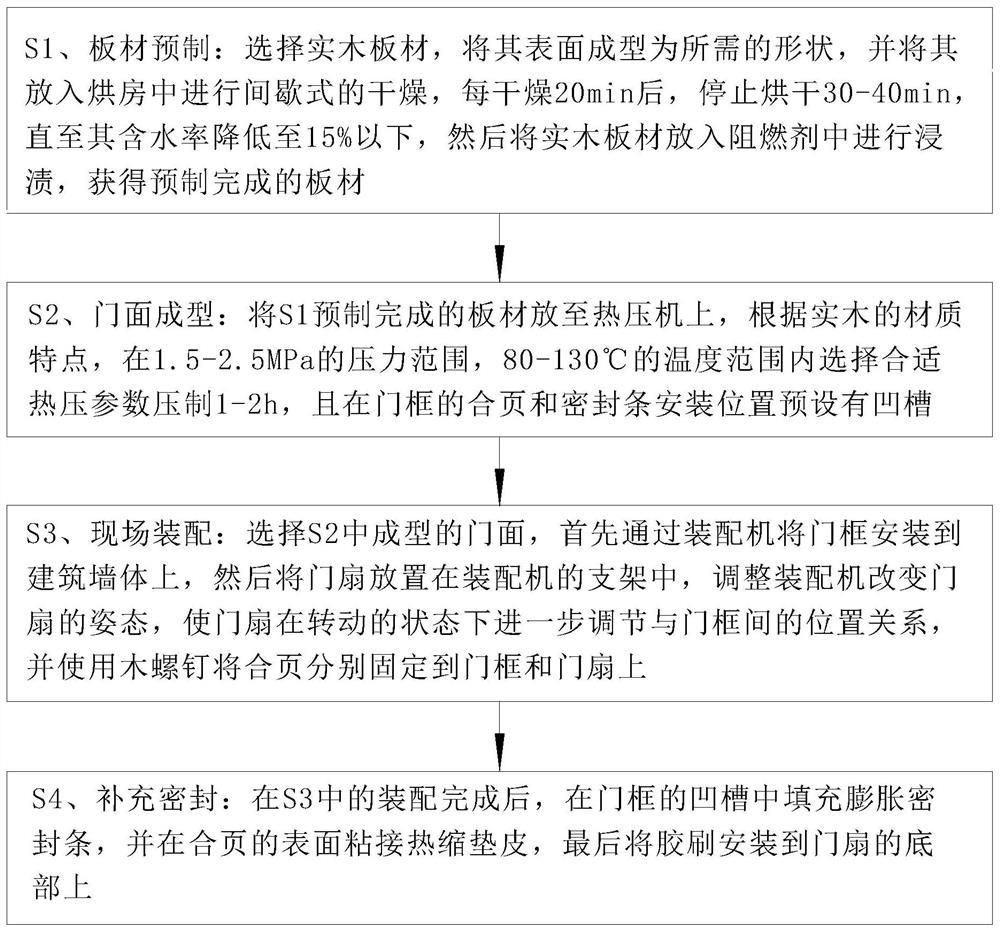

Method used

Image

Examples

Embodiment approach

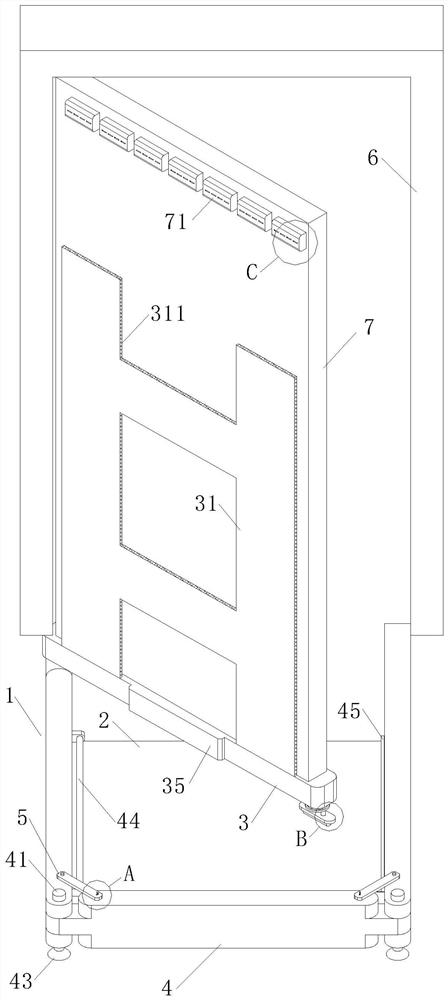

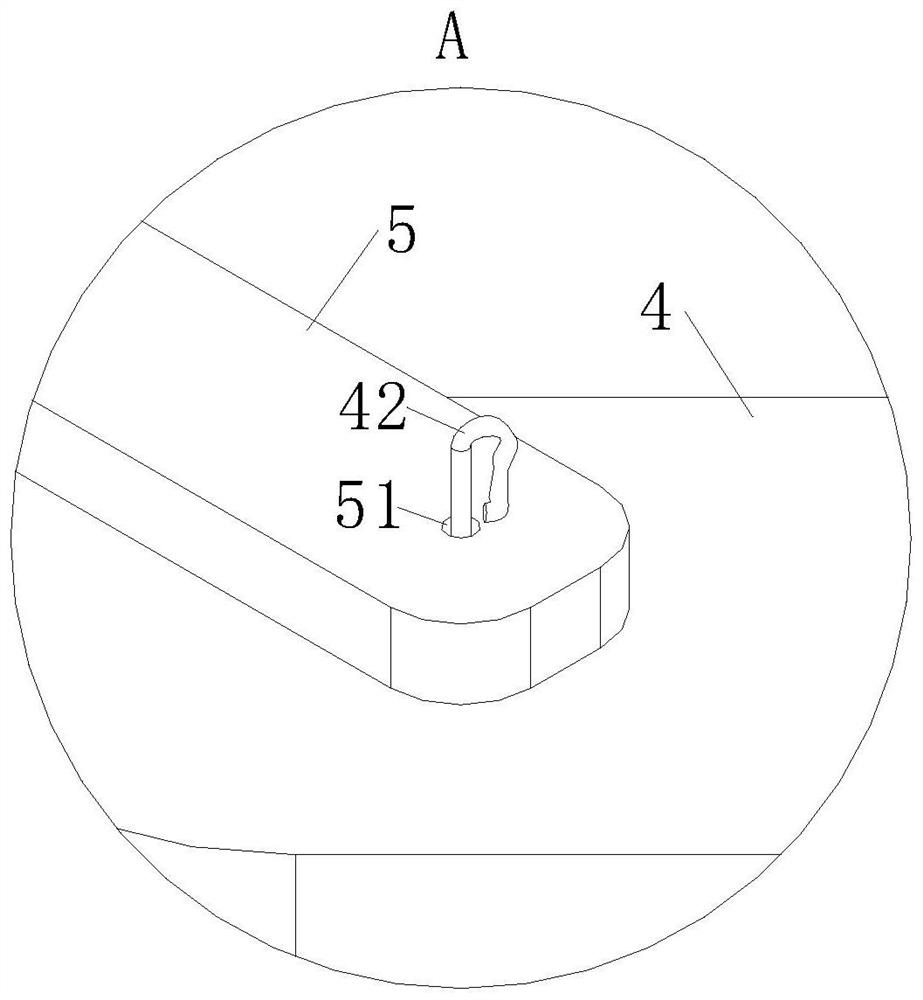

[0038] As an embodiment of the present invention, the supporting plate 31 is also provided with a lining plate 311, the lining plate 311 is a plastic plate material, and the lining plate 311 is used to fill the gap between the door leaf 7 and the supporting plate 31; the door leaf The assembly of 7 needs to be loaded into the supporting plate 31 on the bracket 3. Due to the decorative lines on the surface of the door leaf 7, the clamping state of the door leaf 7 in the supporting plate 31 is not stable enough, which interferes with the door leaf simulated by the rotation of the bracket 3. 7 opening and closing effect; through the lining plate 311 arranged on the supporting plate 31, after the door leaf 7 is loaded into the bracket 3, the lining plate 311 is inserted into the gap between the door leaf 7 and the supporting plate 31, so that the door leaf 7 is stable. It is located in the supporting plate 31, and by adjusting the filling degree of the lining plates 311 on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com