Method for coping with multichannel liquid level signal faults of evaporator in nuclear power station

A signal fault and evaporator technology, applied in nuclear power generation, power plant safety devices, greenhouse gas reduction, etc., can solve problems such as prone to false triggers and imprecise judgments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

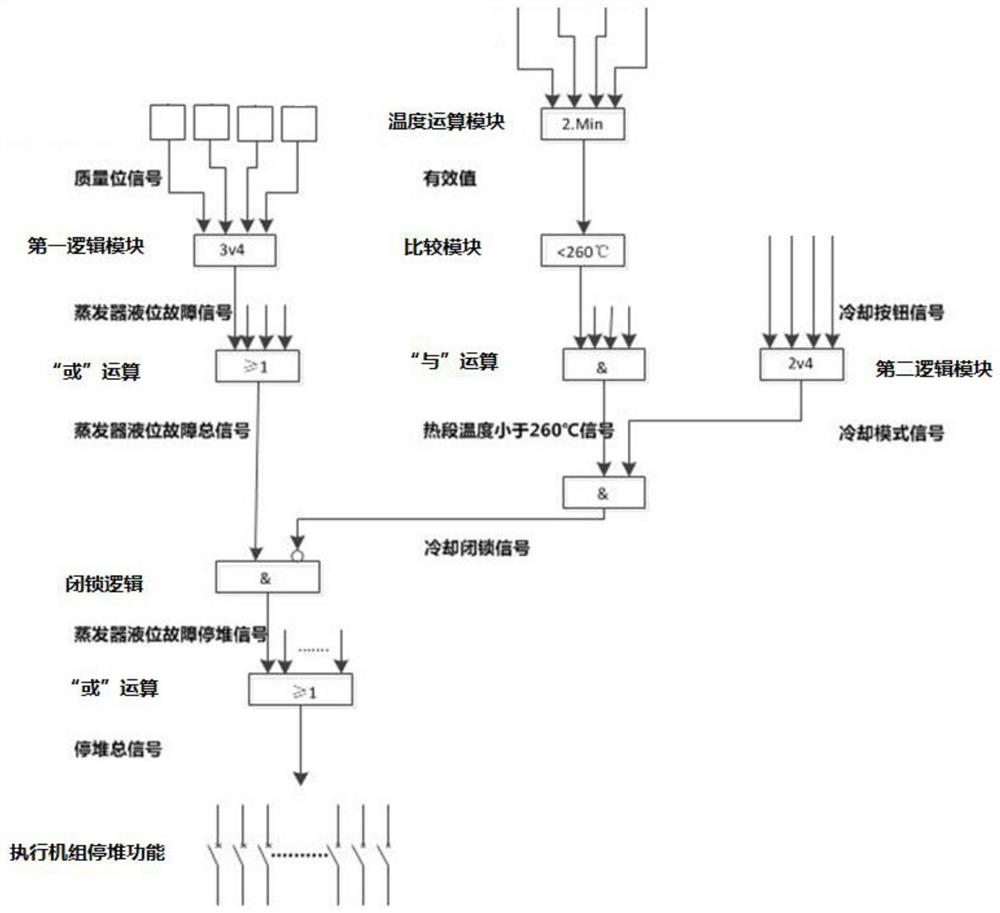

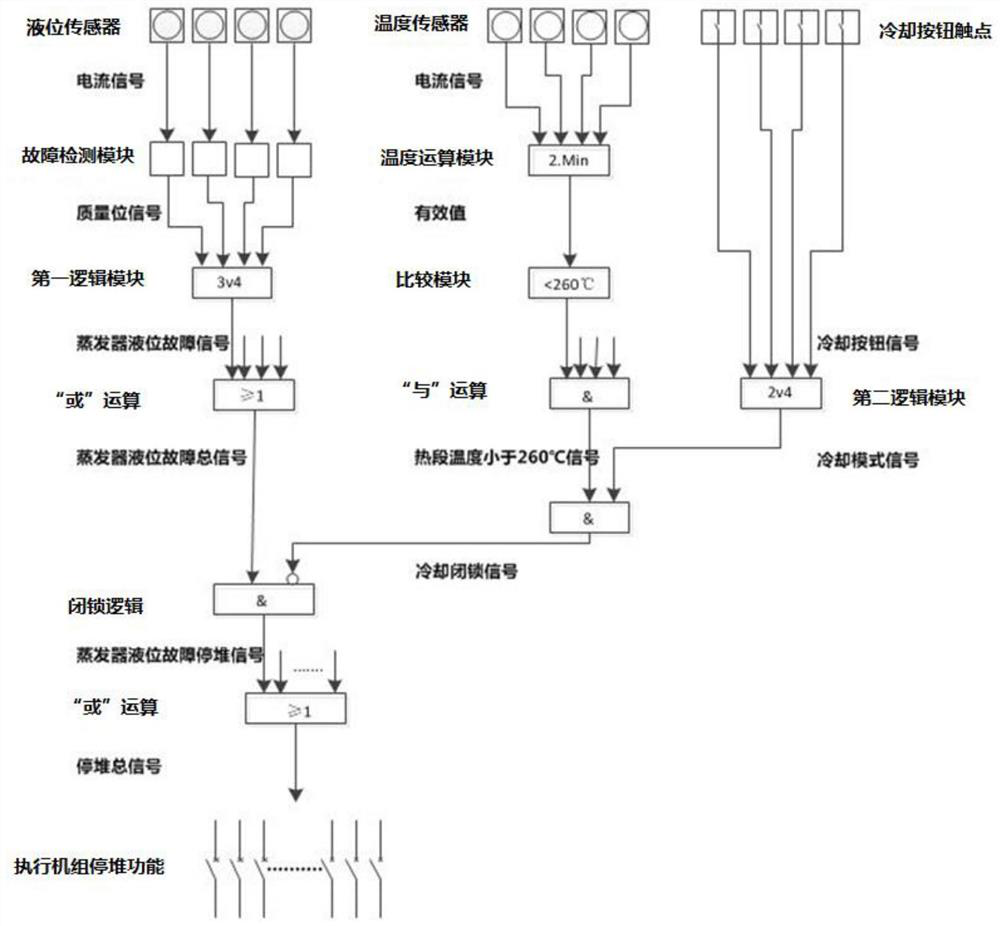

[0083] For details on the process of this embodiment, please refer to figure 2 .

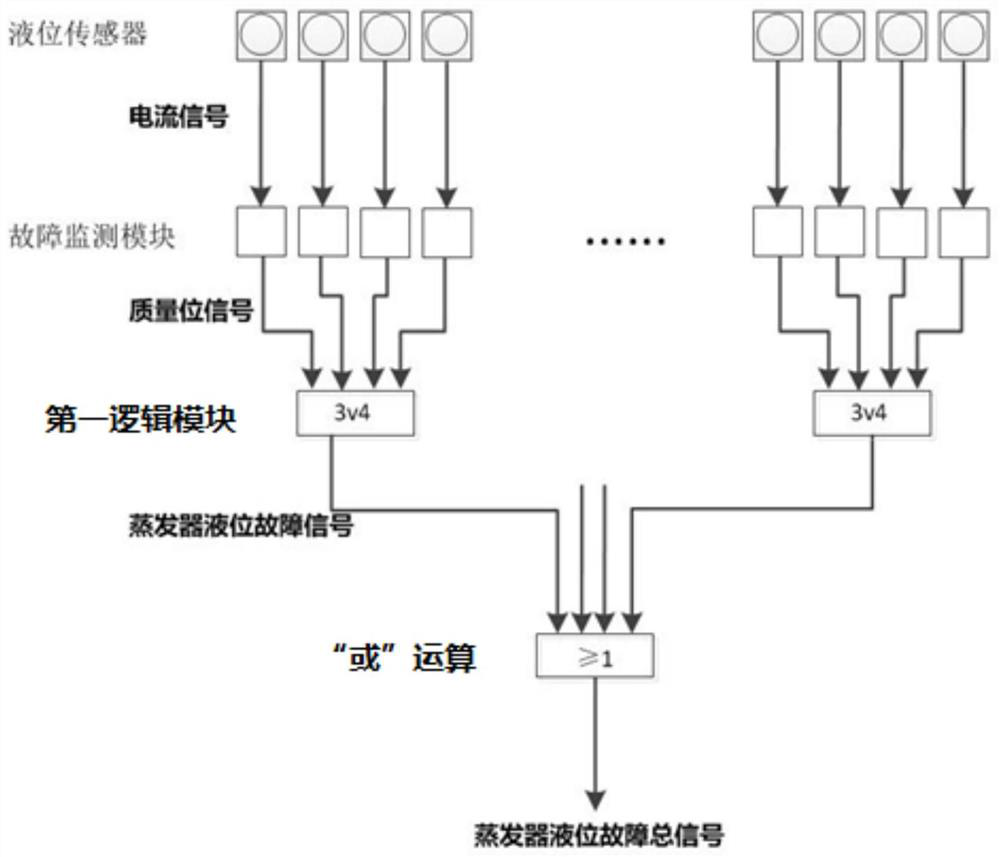

[0084] 1. Generate the total fault signal of multi-channel liquid level signal of the evaporator. For details, see image 3 .

[0085] The liquid level sensor collects the liquid level of the evaporator, generates a 4-20 mA current signal, and sends it to the automatic control system. The 4 mA current corresponds to the lower limit of the liquid level range, and the 20 mA current corresponds to the upper limit of the liquid level range, and the current and the liquid level are linearly related.

[0086] The fault monitoring module generates a quality bit signal according to whether the current signal exceeds ±10% of the range. The fault monitoring module is a logic judgment module based on the automatic control system. The quality level signal is a switch signal. When the current signal exceeds the upper limit of the range by 10% or is lower than the lower limit of the range by 10%, the qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com