Method for non-intrusively determining the temperature of a fluid flowing through a conduit portion

A fluid and section technology, which is applied in the temperature measurement of moving fluid, the application of thermometers with direct heat-sensitive electric/magnetic elements, and the application of thermometers, can solve the problems of not considering the thermal conductivity of the fluid boundary layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

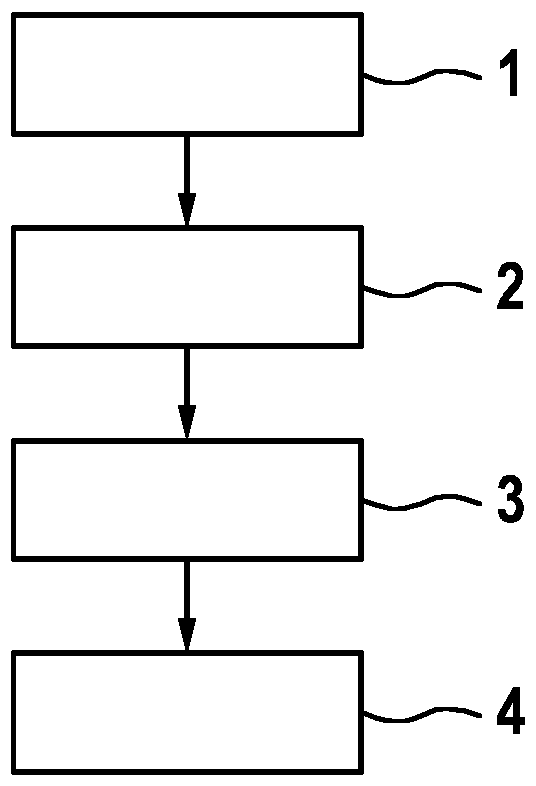

[0065] figure 1 is shown for measuring the flow through the figure 2 The temperature T of the fluid 12 of the conduit section 11 shown in M steps of the method. In a first step 1, the temperature T of the conduit section 11 is determined wa . In a second step 2, a reference temperature T is detected at a distance from the surface 14 of the conduit section 11 e . In a third step 3 , the heat transfer properties, in particular the thermal resistance, of the boundary layer 15 of the fluid 12 at the inner wall 16 of the conduit section 11 are determined as a function of at least one value of a state variable and at least one material property of the fluid 12 .

[0066] In a fourth step 4, depending on the heat transfer properties of the boundary layer 15, the heat transfer properties of the conduit section 11, in particular the thermal resistance, the temperature T of the conduit section wa and reference temperature T e Measure the temperature T of the fluid 12 M . Refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com