A horizontal injection machine

An injection machine, horizontal technology, applied in the field of horizontal injection machines, can solve the problems of small space between fixed and moving templates, inconvenient to take materials, etc., and achieve the effect of reducing labor intensity, improving efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

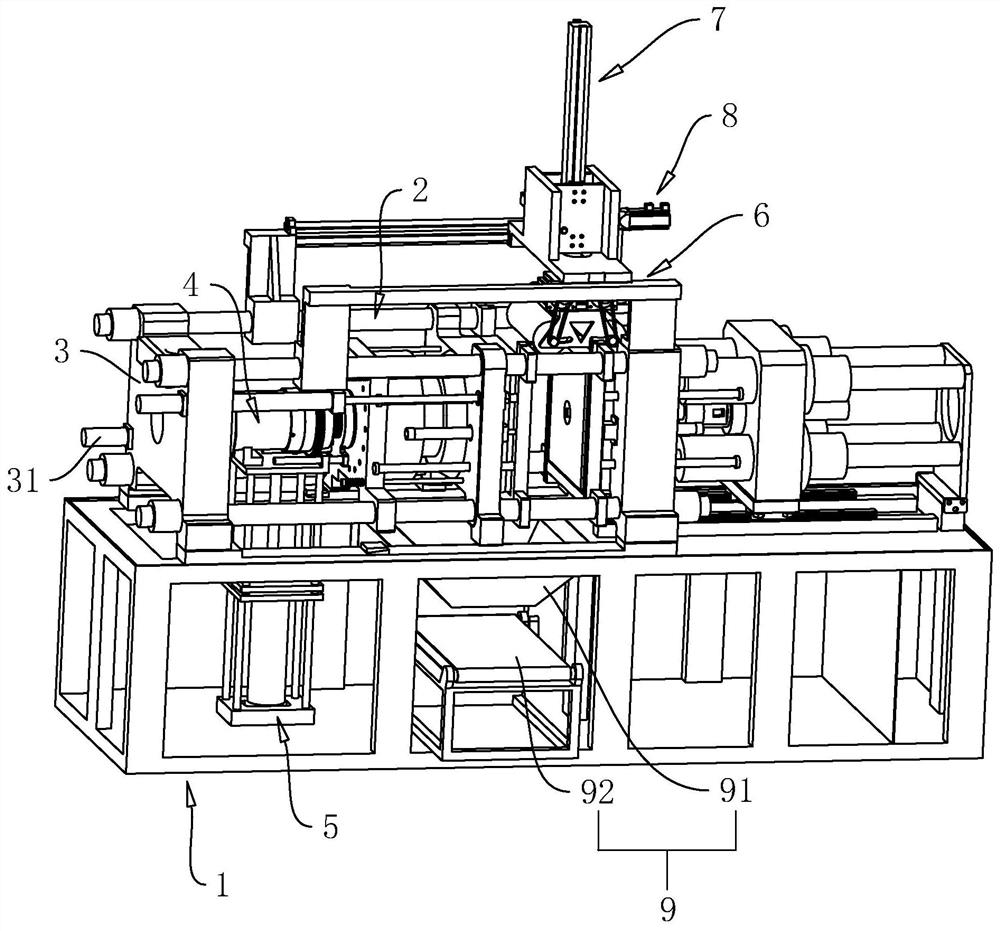

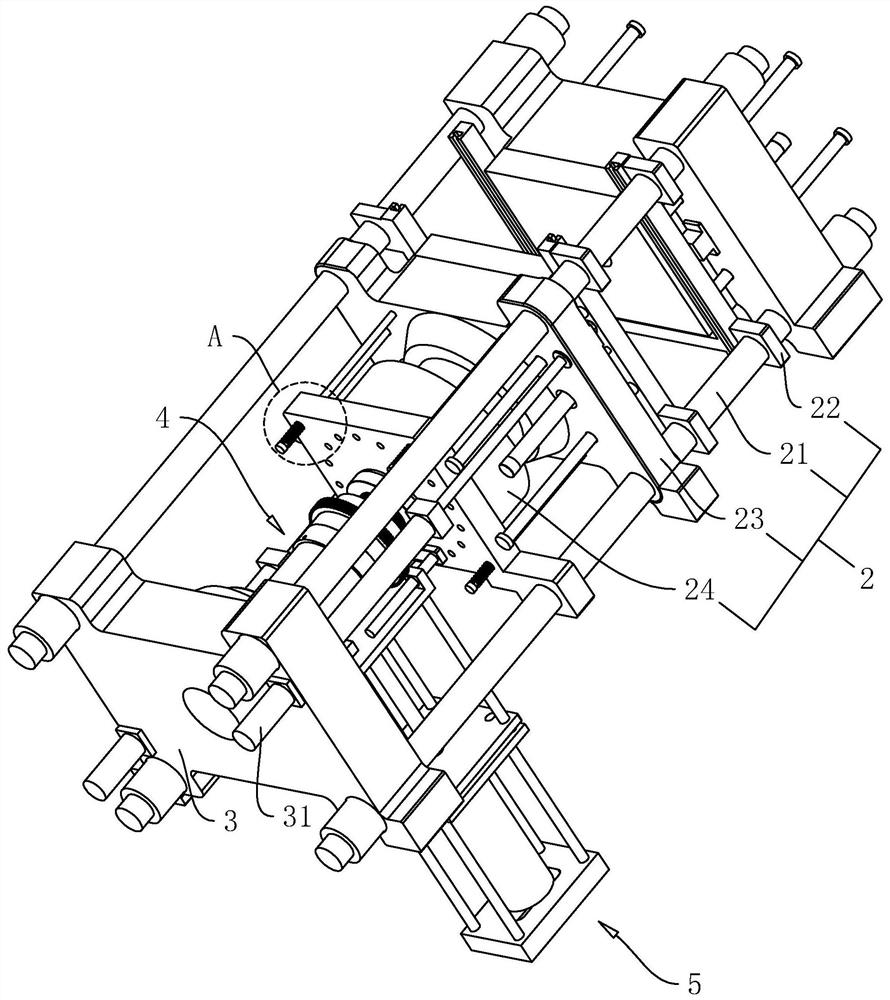

[0042] refer to figure 1 , the horizontal injection machine includes a frame 1 , a mold clamping assembly 2 , a first lifting assembly 5 , a support plate 3 , a first drive source 31 and a support assembly 4 .

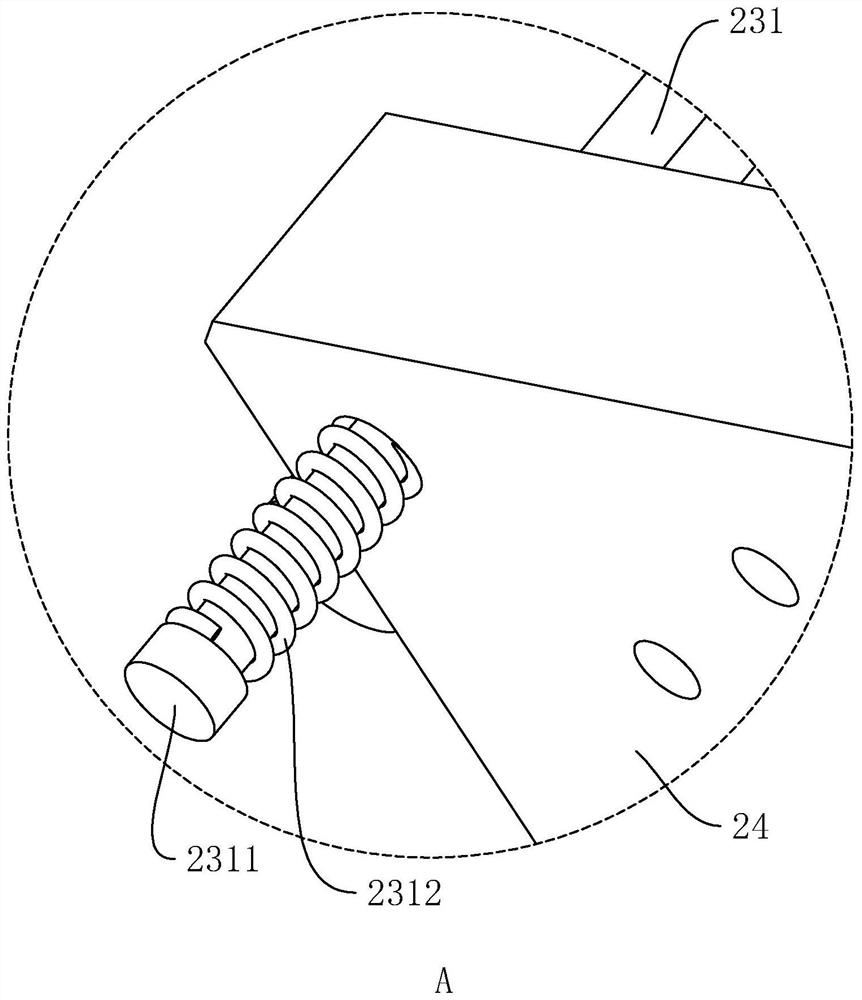

[0043] refer to figure 1 , 2, the clamping assembly 2 includes a clamping machine column 21, a fixed template 22, a moving template 23 and a clamping drive 24; the fixed template 22 and the support plate 3 are both fixed on the upper side of the frame 1, and the clamping machine column 21 The number is at least one, and here the number of the clamping machine columns 21 is four. The ends are in a one-to-one correspondence with the fixed template 22 and the support plate 3; the side of the mold clamping driver 24 is located on the side of the movable template 23 close to the support plate 3, the mold clamping driver 24 is sleeved on the mold clamping machine column 21 and is slidably connected with the mold clamping machine column 21. 24 can be an oil cylinder or an...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is that the lifting cylinder 51 in the first lifting assembly 5 is replaced with an air cylinder or a screw motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com