A cable trench bridge structure

A bridge structure and cable trench technology, which is applied in the field of electric power engineering, can solve problems such as entangled cables and the inability to ensure the orderliness of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

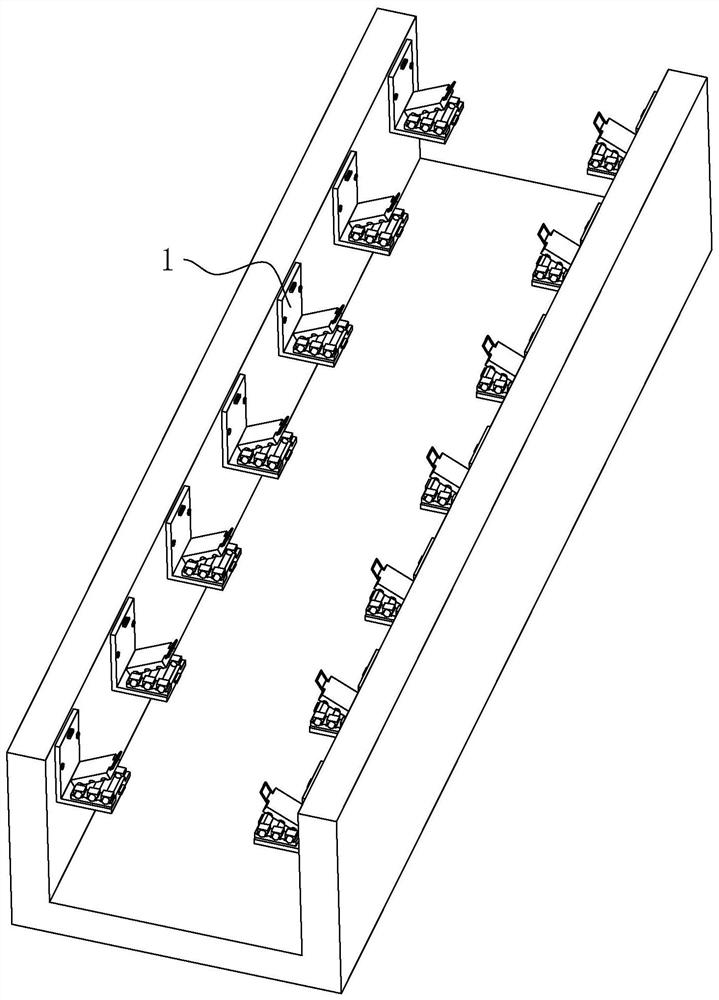

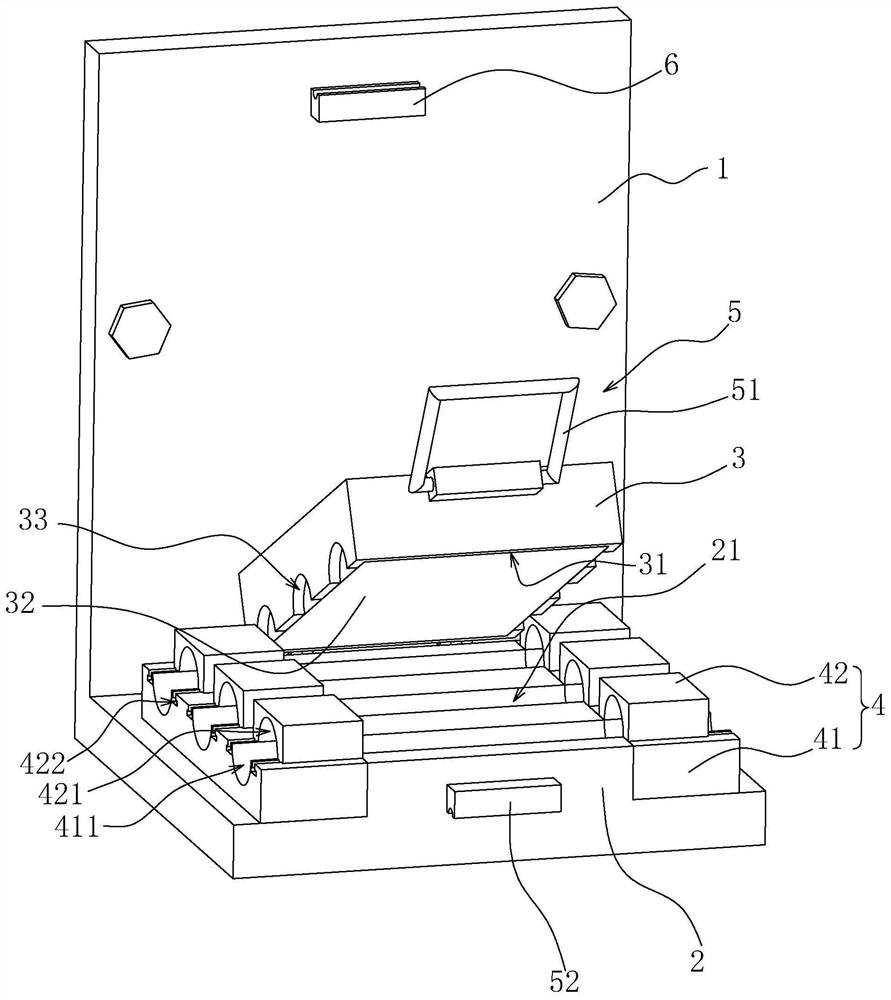

[0040] refer to figure 1 and figure 2 , the bridge structure includes a bridge body 1 arranged on the side wall of the cable ditch, the bridge body 1 is provided with a placement platen 2, and the placement platen 2 is provided with a number of installation grooves 21 consistent with the length direction of the cable trench, and above the placement platen 2 There is also hingedly provided with a pressing seat 3 which cooperates with the placing platen 2 to press the cable.

[0041] refer to figure 2 , a side surface of the pressing seat 3 facing the placing platen 2 is provided with an embedded groove 31, and a flexible pad 32 is arranged in the embedded groove 31. The flexible pad 32 can be rubber, sponge, flexible plastic, etc. with reset ability. The flexible pad 32 is made of elastic material, and the thickness of the flexible pad 32 is equal to the groove depth of the embedded groove 31. After the flexible pad 32 is installed in the embedded groove 31, the end of the ...

Embodiment 2

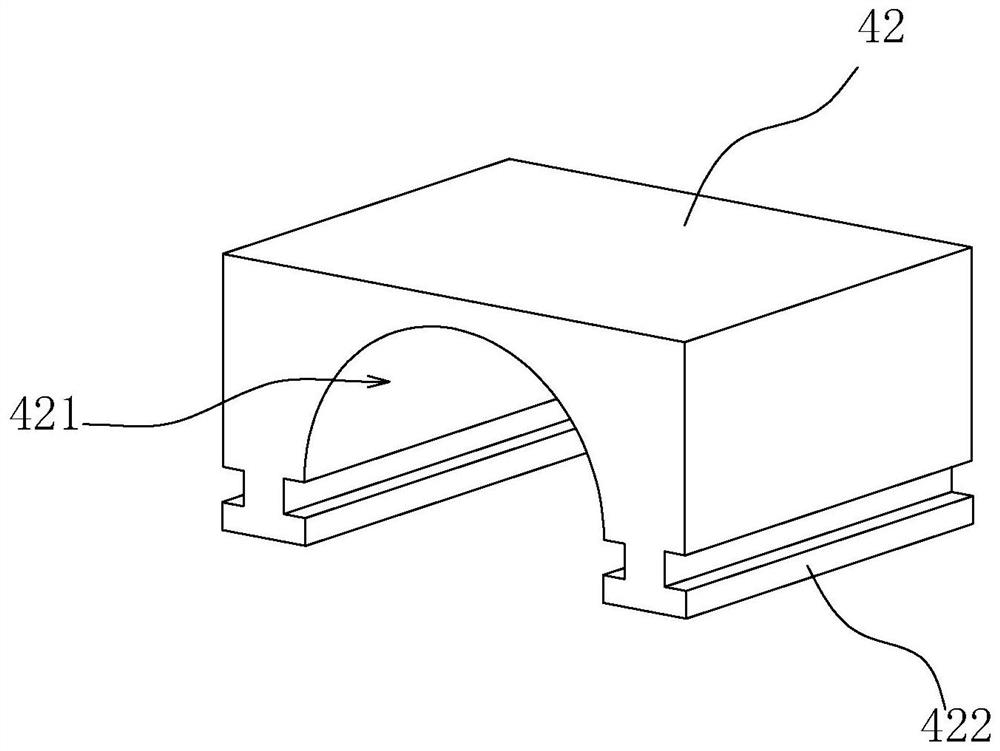

[0050] refer to Figure 4 and Figure 5 The difference between Embodiment 2 and Embodiment 1 is that the locking mechanism 5 is different. In Embodiment 2, the locking mechanism 5 includes a clamping joint 53 arranged at one end of the positioning splint 42, and a clamping joint is provided on the pressing seat 3 53 is inserted into the clamping slot 54, when the clamping joint 53 is inserted into the clamping slot 54, the pressing seat 3 and the placing platen 2 are in a close state. The engaging grooves 54 increase sequentially from the direction of the hinge point of the pressing base 3 to the direction away from the hinge point.

[0051] refer to Figure 5 and Image 6 At the same time, the bottom position in the snap groove 54 is also provided with a positioning protrusion 541, and the bottom of the snap joint 53 is provided with a positioning groove 531 for the positioning protrusion 541 to be inserted into. The aperture of the positioning groove 531 is also larger th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com