Polycrystalline diamond composite sheet and its preparation method

A polycrystalline diamond and composite sheet technology, which is applied in earthwork drilling, drilling equipment, drill bits, etc., can solve the problem of short service life of diamond composite sheets, weak wear resistance and impact resistance of the polycrystalline layer, uneven thickness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

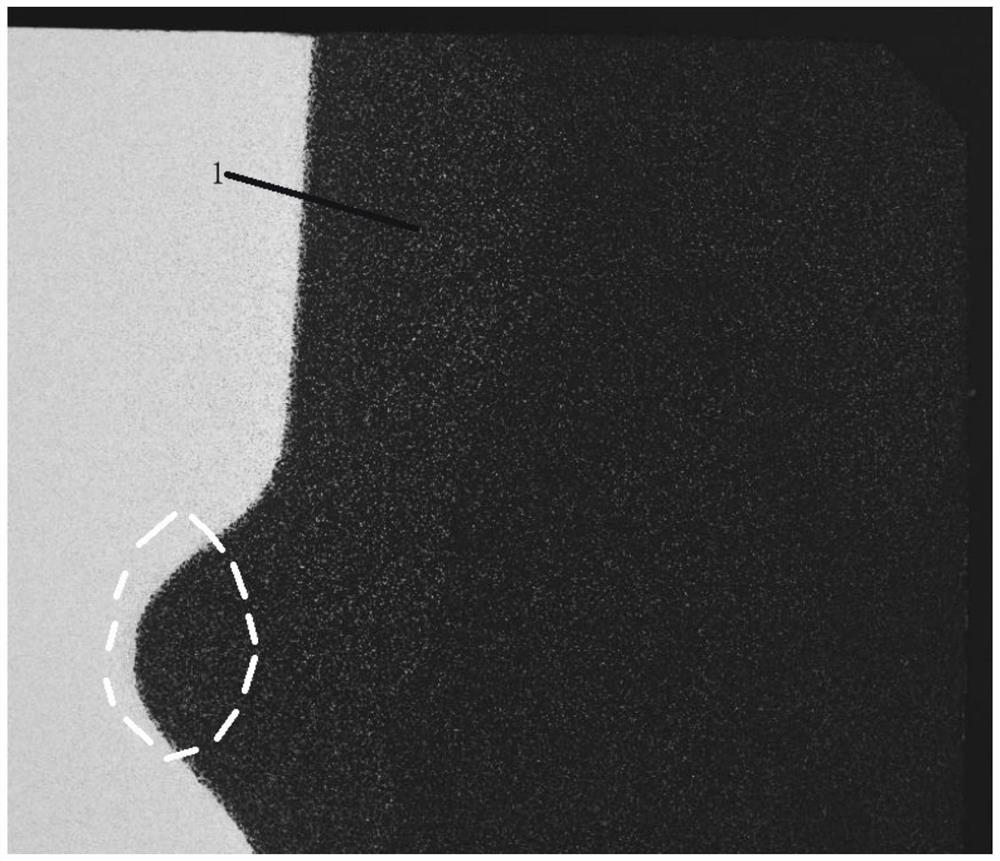

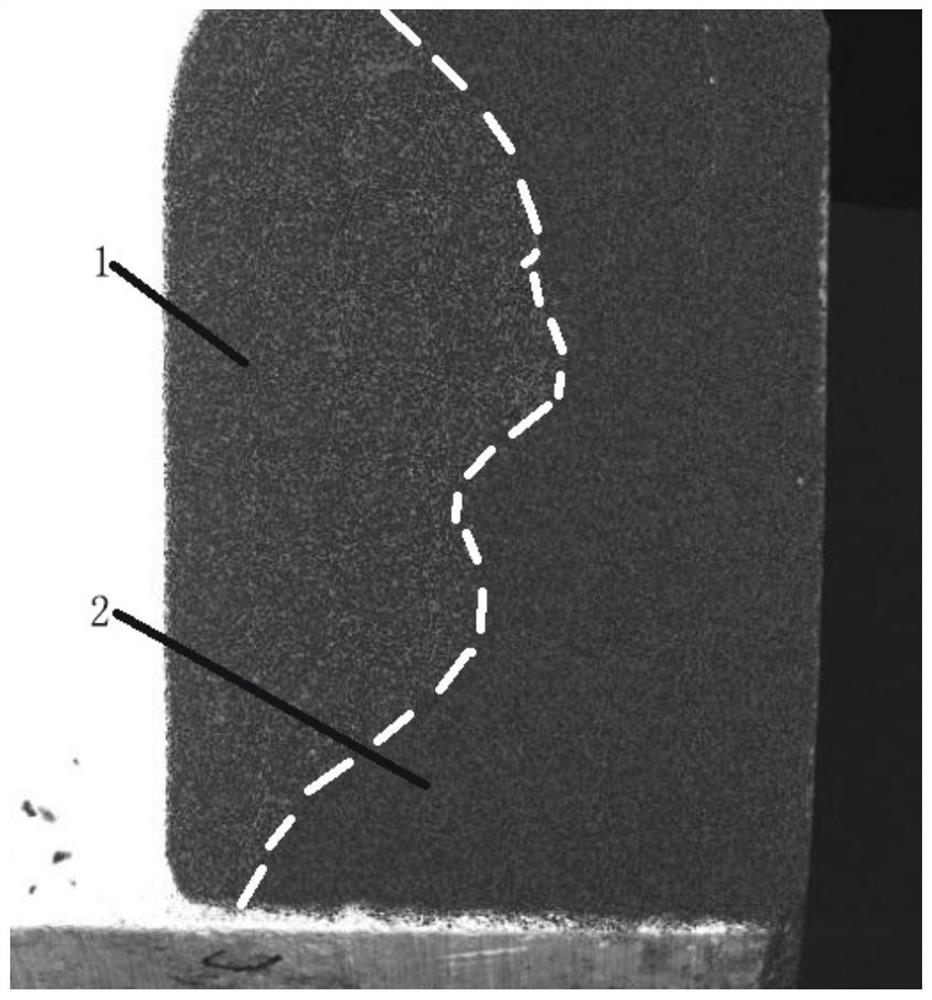

Image

Examples

Embodiment 1

[0046] The diamond composite sheet of embodiment 1 is prepared by the above-mentioned polycrystalline diamond composite sheet, and the sum of the thicknesses of the working layer and the transition layer is 2.2 mm, wherein the outer chamfer of the compact used in the pre-compression molding step and the transition layer step The angle is 15°~20°.

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is that the angle of the outer chamfer of the compact used in the pre-pressing step and the transition layer step is 20°-30°.

[0049] Implementation group 2

[0050] Through the comparison of experimental group 2, under the same diamond layer thickness and the same outer chamfering angle of the compact, but the thickness of the working layer and the thickness of the transition layer are different, the impact resistance and wear resistance of the diamond composite sheet are tested.

Embodiment 3

[0052] The diamond composite sheet in Example 3 is prepared by the method for preparing the polycrystalline diamond composite sheet, wherein the angle of the outer chamfer of the compact is 15° to 20°, the thickness of the working layer is 1.85mm, and the thickness of the transition layer is 0.35mm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com