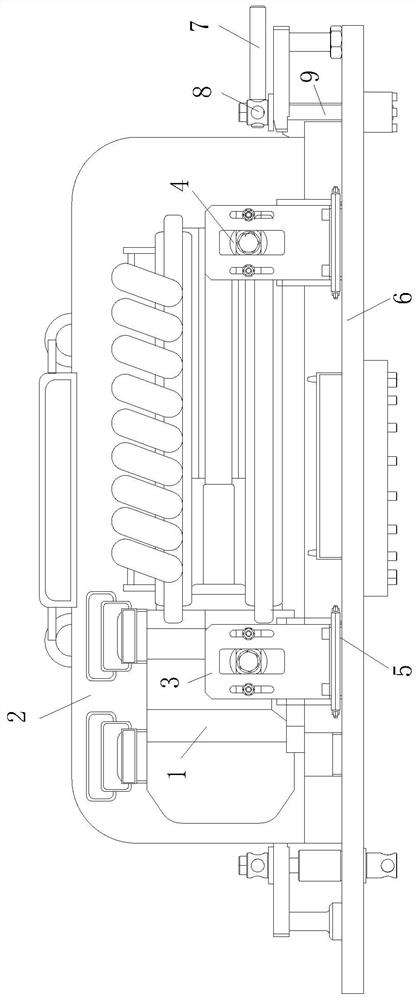

Lightweight turbo-compressor

A turbo compressor, lightweight technology, applied in the field of compressors, can solve the problems of large internal noise, large vibration of the compressor as a whole, high internal temperature, etc., and achieve the effect of reducing external vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

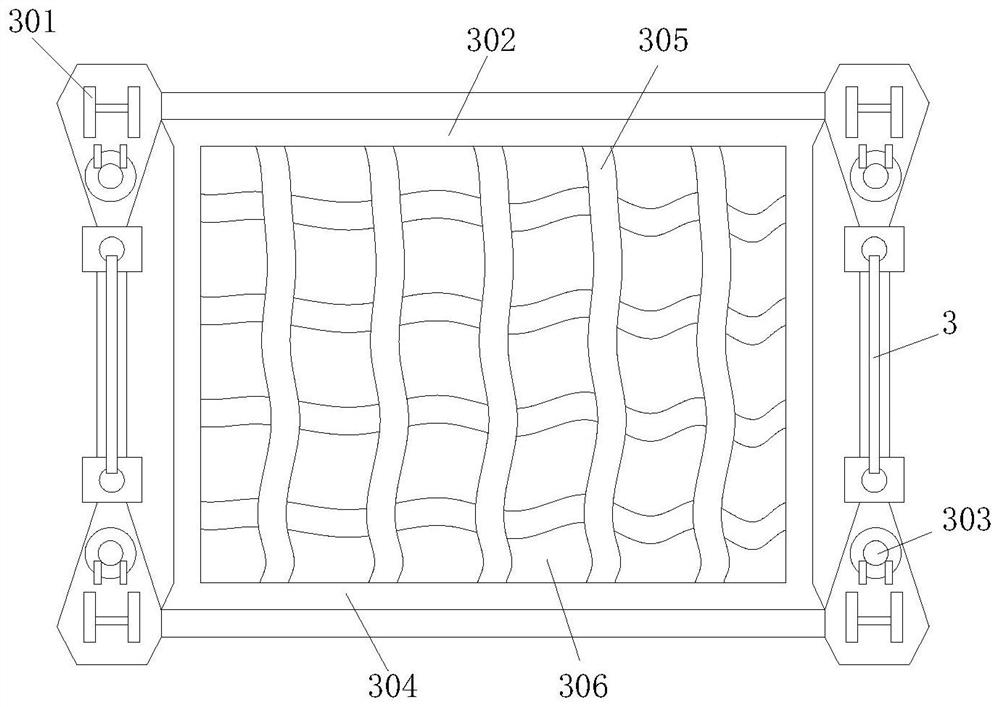

[0026] As an embodiment of the present invention, the fixing mechanism 3 includes a connecting plate 301, a heat dissipation net 302 and a buckle post 303. There is a heat dissipation net 302 in the middle of the fixing mechanism 3, and the fixing mechanism 3 and the heat dissipation net 302 There is a movable connection between the two sides of the fixing mechanism 3 close to the cooling net 302, and the connecting plate 301 and the cooling net 302 are connected flexibly; the upper and lower sides of the connecting plate 301 are installed with card Buckle column 303, and the inner inner wall of the connecting plate 301 and the outer outer wall of the buckle column 303 are closely fitted, and the connecting plate 301 is formed into a disassembly structure through the heat dissipation net 302 and the buckle column 303; The sliding of the buckle post 303 between the connecting plates 301 makes the heat dissipation net 302 on the fixing mechanism 3 loose, so that it is convenient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com