Composite induction disc high-speed eddy current brake

An eddy current brake and induction disc technology, applied in asynchronous induction clutches/brakes, permanent magnet clutches/brakes, electric brakes/clutches, etc. The effect of wide dynamic speed range, safe and reliable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

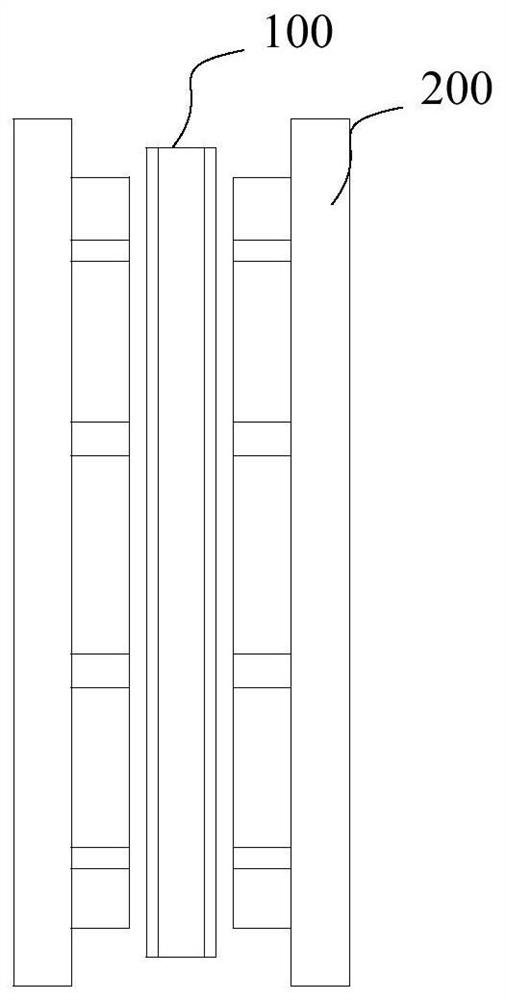

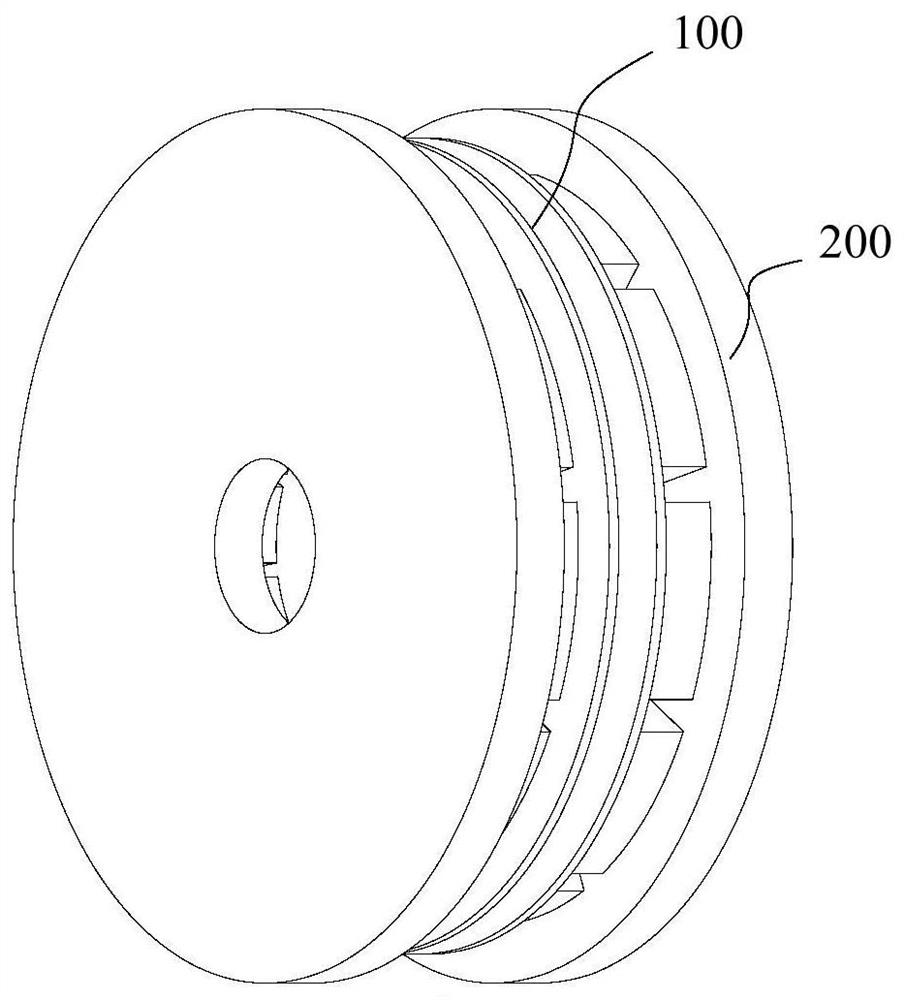

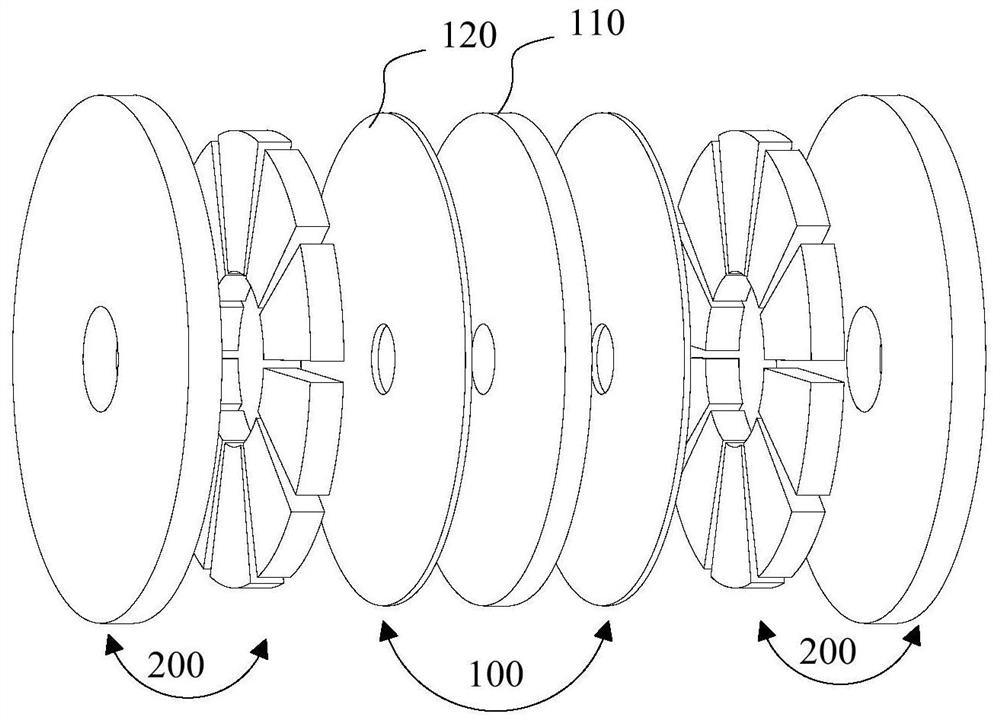

[0047] Specific implementation mode 1. Combination Figure 1 to Figure 11As shown, the first aspect of the present invention provides a composite induction disc high-speed eddy current brake, comprising an induction disc 100 and two excitation discs 200, the two excitation discs 200 are located on both axial sides of the induction disc 100, and respectively An air gap is formed between the induction disks 100; the two excitation disks 200 are mechanically connected together;

[0048] Both the induction disk 100 and the excitation disk 200 are circular;

[0049] The induction disk 100 includes a high-permeability conductor plate 110 and two high-conductivity conductor plates 120, and the two high-conductivity conductor plates 120 are respectively pasted and fixed on both axial sides of the high-permeability conductor plate 110;

[0050] The axial thickness at the outer diameter of the high-conductivity conductor plate 120 is less than or equal to the axial thickness at the inn...

specific Embodiment 1

[0057] Specific embodiment one: combine Figure 1 to Figure 7 As shown, the composite induction disc high-speed eddy current brake is mainly composed of two excitation discs, an induction disc and two air gaps, and the two excitation discs are located on both axial sides of the induction disc, and between the two excitation discs and the induction disc For two air gaps, the two exciters are mechanically connected together. The induction plate is composed of two conductor plates made of disc-shaped high-conductivity materials and one conductor plate made of disc-shaped high-magnetic-permeability materials. The two conductor plates made of high-conductivity materials are pasted and fixed on the disc-shaped high magnetic The axial thickness at the outer diameter of the conductor plate made of high-conductivity material is equal to the axial thickness at the inner diameter of the conductor plate made of high-conductivity material, and the axial thickness of the outer diameter of t...

specific Embodiment 2

[0058] Specific embodiment two: combine Figure 8 to Figure 11 As shown, the main difference between this embodiment and specific embodiment 1 is that the axial thickness at the outer diameter of the conductor plate made of high electrical conductivity material is smaller than the axial thickness at the inner diameter, and the outer diameter of the conductor plate made of high magnetic permeability material The axial thickness at the diameter is greater than the axial thickness at the inner diameter. In this embodiment, the thickness of the conductor plate made of high electrical conductivity material and the conductor plate made of high magnetic permeability material changes gradually along the radial direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com