Coupled torsion beam axle apparatus of vehicle

A technology of torsion beams and axles, applied in vehicle components, transportation and packaging, interconnection systems, etc., can solve the problems that the torsion bar position cannot be changed, the torsion bar cannot be replaced, and the torsion bar cannot be replaced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

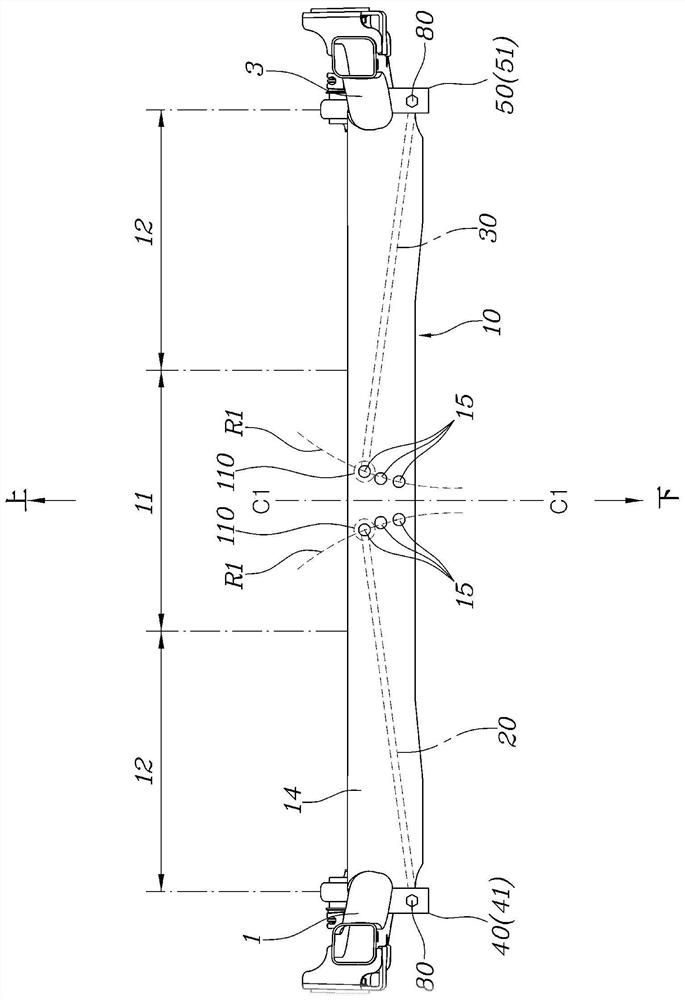

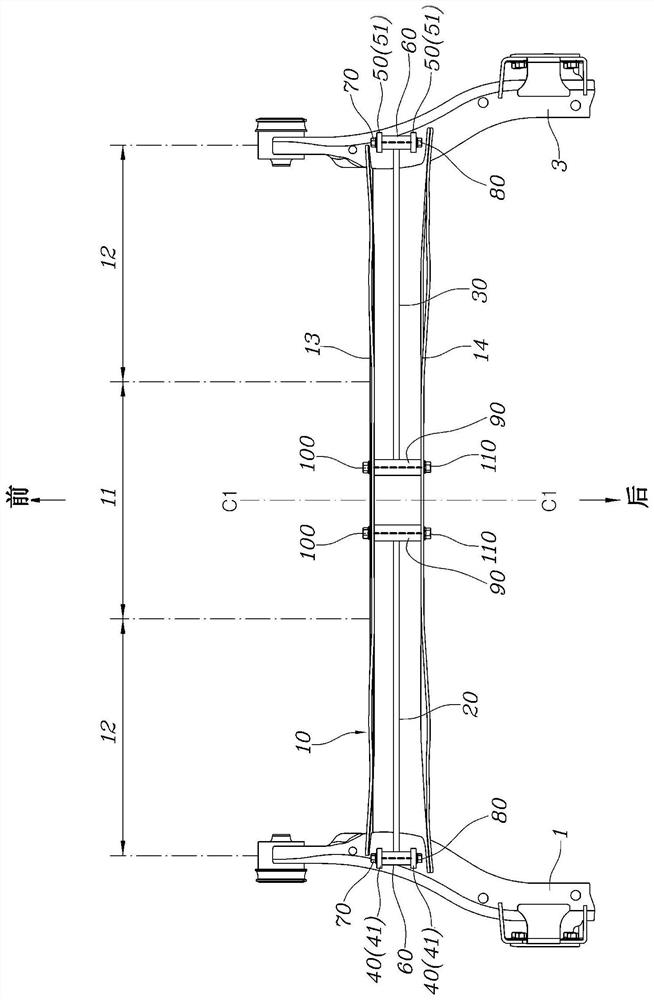

[0028] Hereinafter, a torsion beam type axle combined apparatus for a vehicle according to an exemplary embodiment of the present invention is described with reference to the accompanying drawings.

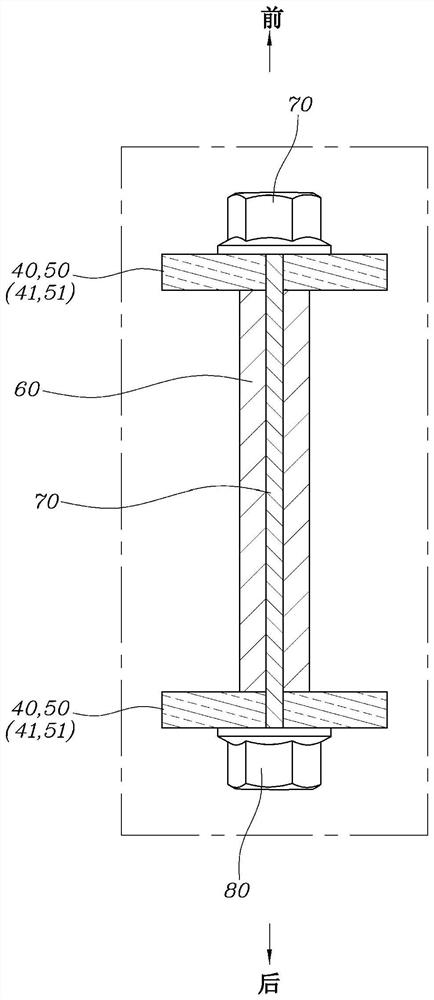

[0029] Such as Figure 1 to Figure 6 As shown, the combined torsion beam type axle apparatus for a vehicle according to an exemplary embodiment of the present invention includes: a torsion beam 10 formed in an open loop shape having a U-shaped or V-shaped cross section and opening downward. , arranged in the horizontal direction, and respectively connected to the left trailing arm 1 and the right trailing arm 3; separated from each other.

[0030] The left side (left end) of the left torsion bar 20 is coupled to any one of the left trailing arm 1 and the torsion beam 10, and the right side (right end) of the right torsion bar 30 is coupled to any one of the right trailing arm 3 and the torsion beam 10. , the right side (right end) of the left torsion bar 20 and the left side (le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com