A method for producing gasoline by hydrogenation conversion of aromatics-containing diesel fraction

A hydrogenation conversion and diesel oil technology, which is applied in the direction of hydrocarbon oil treatment products, hydrocarbon oil treatment, hydrotreatment process, etc., can solve the problems of fast catalyst deactivation rate, low octane number of gasoline products, short operation cycle, etc., to achieve The effect of reducing oversaturation, accelerating the rate of inactivation, and extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

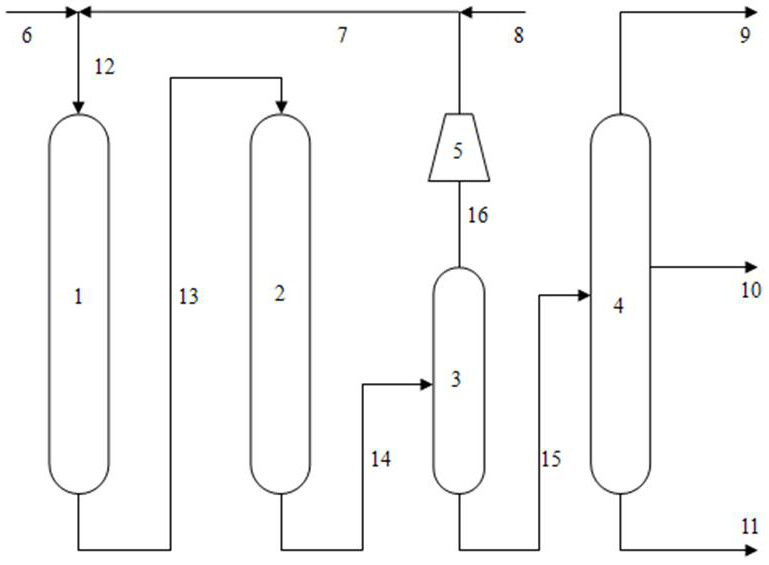

[0045] use figure 1 process shown. There are two reactors, R1 is a hydrogenation pretreatment reactor, and R2 is a hydrogenation conversion reactor. R1 is filled with catalyst A, and R2 is filled with catalyst B. The volume space velocity of the refining reactor is 1.5h -1 , the conversion reactor volume space velocity is 1.5h -1 , the maximum operating pressure of the device is 10.0 MPa, the maximum operating temperature is 405°C, the maximum operating total temperature rise is 100°C, the design conversion rate is >40 wt%, and the octane number of the gasoline product research method is ≮90.

[0046] The methods include:

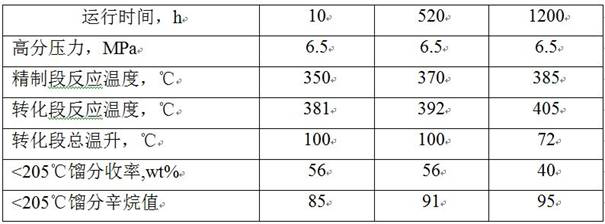

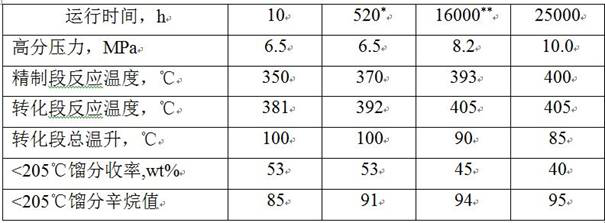

[0047] (1) In the initial stage of operation, the reaction pressure is 6.3MPa, and the initial reaction temperature is 381°C; gradually increase the reaction temperature of the reforming reactor so that the total bed temperature rise reaches the operating upper limit of 100°C, and the octane number of gasoline products reaches the standard after 520 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com