A method for catalytic hydrogenation conversion of diesel oil containing aromatics

A technology for hydroconversion and catalytic hydrogenation, which is applied in the treatment of hydrocarbon oil, hydrocarbon oil treatment products, and hydrotreating processes, etc., can solve the problems of low octane number of gasoline products, ensure long-term operation and reduce excessive Saturation, the effect of raising the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

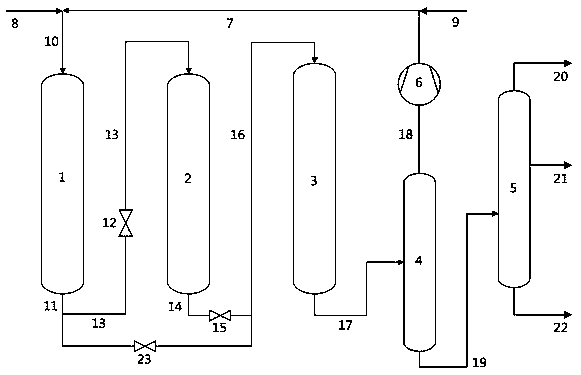

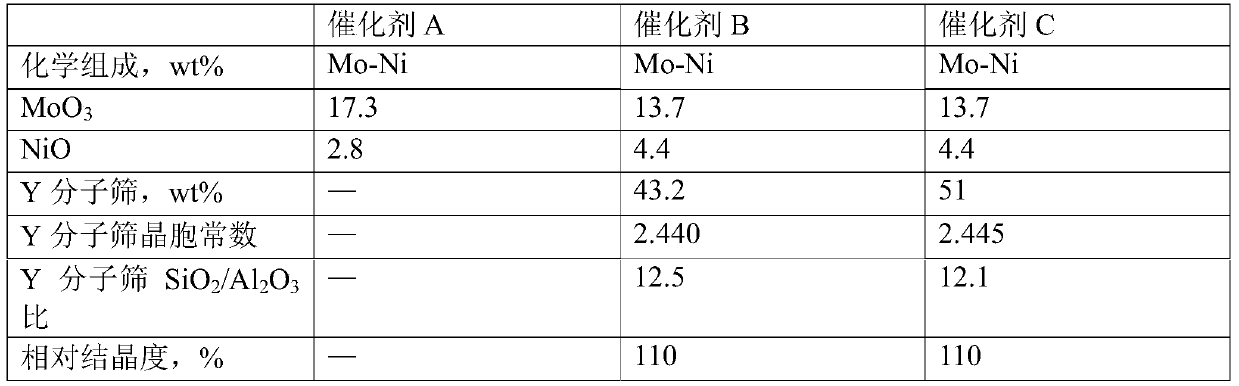

[0040] use figure 1 process shown. There are three reactors, R1 is a hydrogenation pretreatment reactor, R2 and R3 are hydrogenation conversion reactors. R1 is filled with catalyst A, R2 is filled with catalyst B, and R3 is filled with catalyst B. In the initial stage of operation, R2 is short-circuited, FCC diesel and hydrogen are mixed into R1, and the effluent is obtained into R3 to obtain products, which are separated and fractionated to obtain gas, gasoline products and diesel products. After 5,500 hours of operation, the process is changed, and R2 is cut into the process flow: FCC diesel is mixed with hydrogen and enters R1, the obtained effluent enters R2, and the obtained effluent enters R3, and the obtained products are separated and fractionated to obtain gas, gasoline products and diesel products. Process conditions and product properties are shown in Table 3.

Embodiment 2

[0044] use figure 1 process shown. There are three reactors, R1 is a hydrogenation pretreatment reactor, R2 and R3 are hydrogenation conversion reactors. R1 is filled with catalyst A, and R2 and R3 are filled with catalyst B. At the initial stage of operation, R2 is short-circuited, raw material oil and hydrogen are mixed into R1, and the effluent is obtained into R3 to obtain products, which are separated and fractionated to obtain gas, gasoline products and diesel products. After 5,500 hours of operation, the process is changed, and R2 is cut into the process flow: the raw material oil is mixed with hydrogen and enters R1, the obtained effluent enters R2, and the obtained effluent enters R3, and the obtained products are separated and fractionated to obtain gas, gasoline products and diesel products. Process conditions and product properties are shown in Table 5.

Embodiment 3

[0046] use figure 1 process shown. There are three reactors, R1 is a hydrogenation pretreatment reactor, R2 and R3 are hydrogenation conversion reactors. R1 is filled with catalyst A, R2 is filled with catalyst C, and R3 is filled with catalyst B. In the early stage of operation, R2 is short-circuited, raw material oil and hydrogen are mixed into R1, and the effluent is obtained into R3 to obtain products, which are separated and fractionated to obtain gas, gasoline products and diesel products. After 5,500 hours of operation, the process is changed, and R2 is cut into the process flow: the raw material oil is mixed with hydrogen and enters R1, the obtained effluent enters R2, and the obtained effluent enters R3, and the obtained products are separated and fractionated to obtain gas, gasoline products and diesel products. Process conditions and product properties are shown in Table 6.

[0047] Table 3 process conditions and product properties

[0048] running time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com