X-ray flaw detection automatic calibrating device

An automatic verification and X-ray technology, which is applied in the field of X-ray flaw detection, can solve the problems of no storage, the position height cannot be adjusted, the X-ray flaw detection instrument cannot be used normally, etc., and the effect of saving time and effort is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

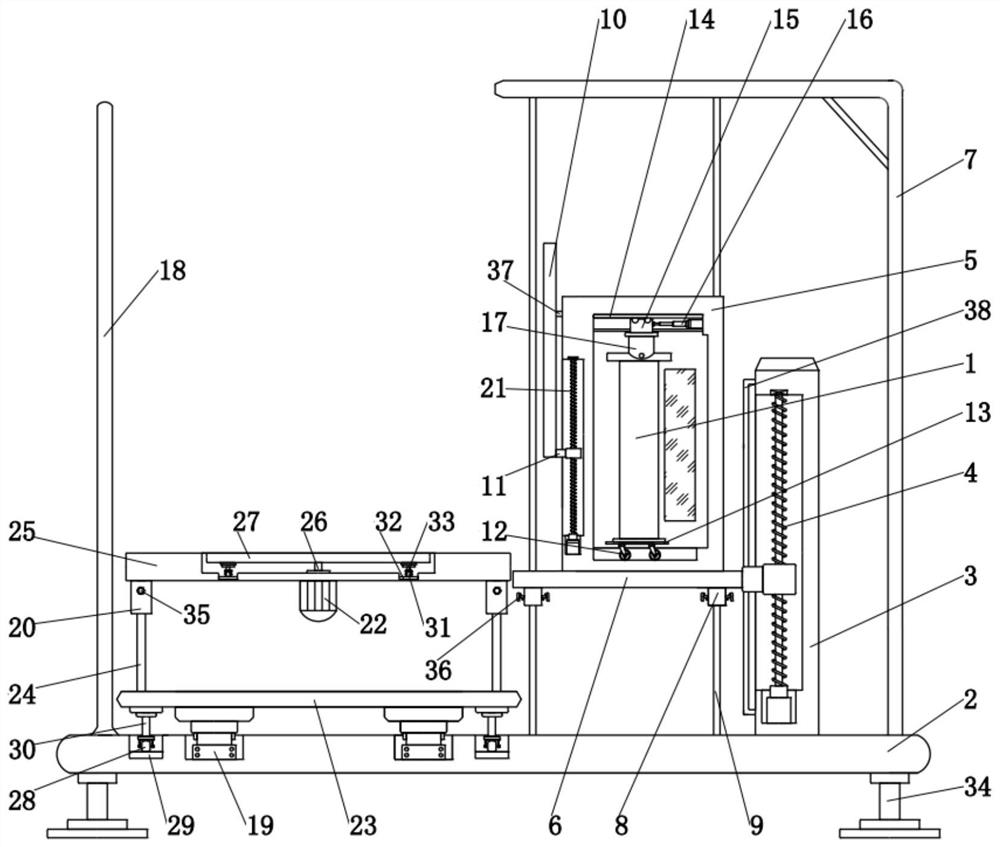

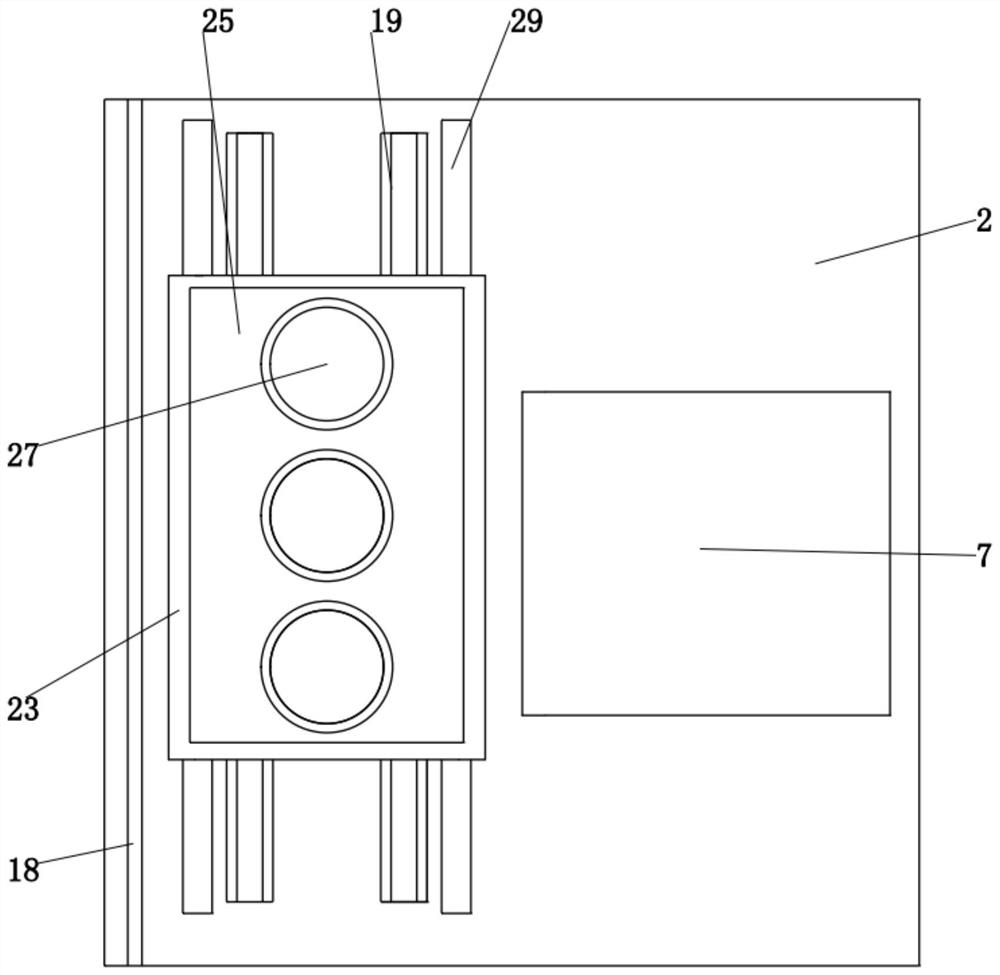

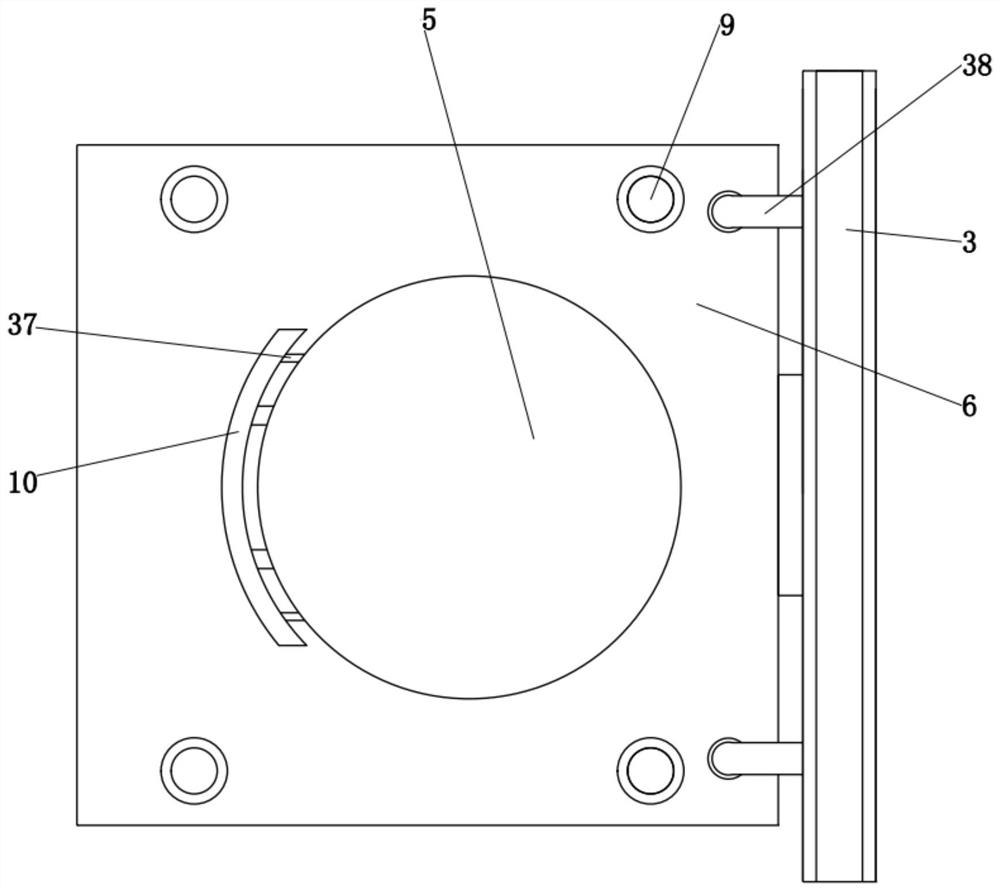

[0028] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7As shown, an X-ray flaw detection automatic verification device includes an X-ray flaw detector 1 and a rectangular base 2, the rectangular base 2 is provided with a lifting support structure, the X-ray flaw detector 1 is installed on the lifting support structure, and the lifting support structure A shielding structure for protecting the X-ray flaw detector 1 is provided on the top, and an object bearing structure is provided on the upper wall of the rectangular base 2 and located on the right side of the X-ray flaw detector 1; the lifting support structure includes: a support frame 3, a first screw module 4 And the storage box 5; the support frame 3 is installed on the upper wall of the rectangular base 2, and is close to the left end, the side wall of the support frame 3 is provided with a first bar-shaped groove, and the first lead screw module 4 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com