Optical glass, glass preforms, optical components and optical instruments

A technology of optical glass and mole percentage, which is applied in optical components, instruments, optics, etc., can solve the problems of shortening the service life of optical glass and reducing glass performance, and achieves excellent sunlight resistance stability, large degree of freedom, and low refractive index temperature The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0091]

[0092] In order to further clearly illustrate and illustrate the technical solution of the present invention, the following non-limiting examples are provided.

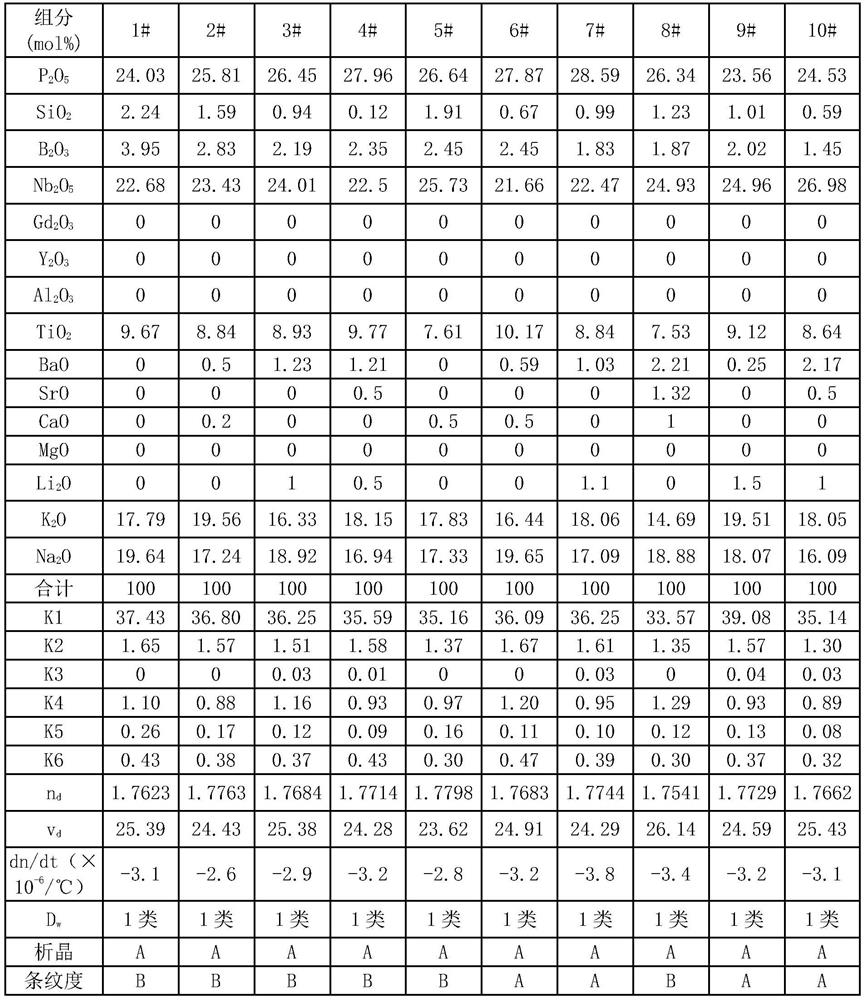

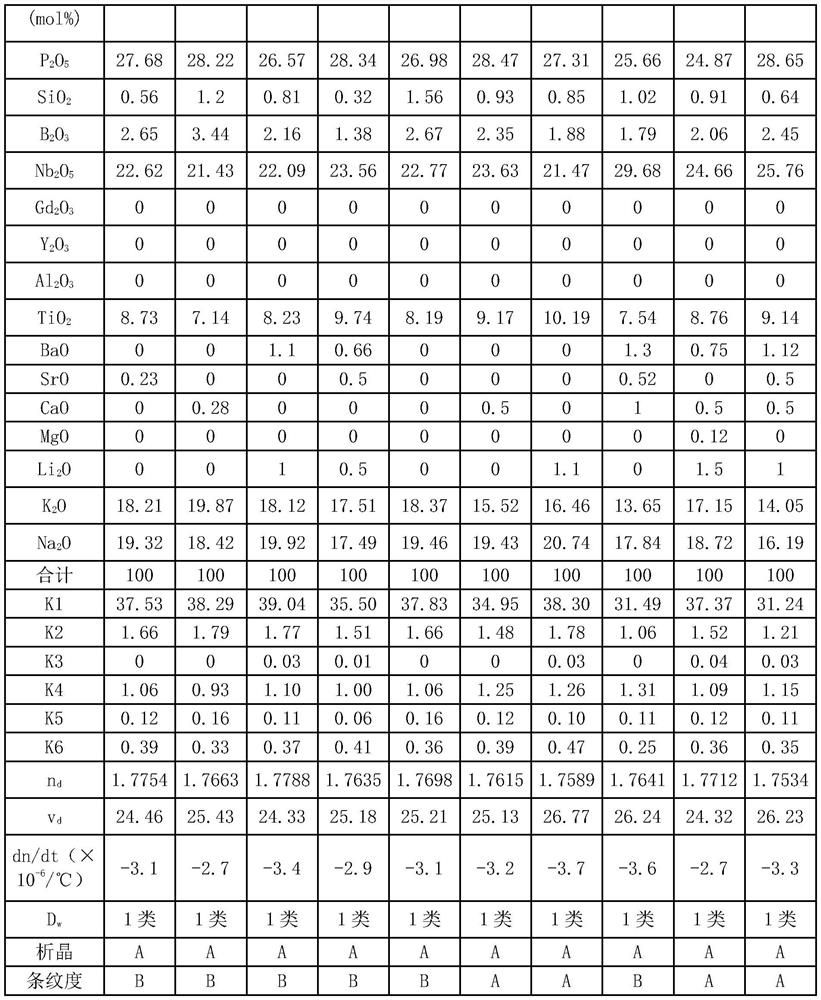

[0093] In this embodiment, the above-mentioned manufacturing method of optical glass was used to obtain the optical glass shown in Table 2-Table 3. In addition, the properties of each glass were measured by the test method described in the present invention, and the measurement results are shown in Tables 2 to 3. In Table 2~Table 3, R 2 O is represented by K1; R 2 O / Nb 2 o 3 The value is represented by K2; Li 2 O / R 2 The value of O is expressed in K3; Na 2 O / K 2 The value of O is expressed in K4; (SiO 2 +B 2 o 3 ) / P 2 o 5 The value is expressed in K5; TiO 2 / Nb 2 o 5 The value of K6 is represented by K6; in the anti-devitrification performance test, no obvious devitrification is recorded as "A", and obvious devitrification is recorded as "B".

[0094] Table 2.

[0095]

[0096] table 3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com