Composite response foamed rubber-plastic sole, preparation method thereof and sports shoes

A compound response and foam rubber technology, which is applied in the field of sports shoes and compound response foam rubber and plastic soles, can solve the problems of multiple hardness and functional response of difficult soles, and achieve the effect of improving sports experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a kind of preparation method of composite response foam rubber-plastic shoe sole, comprises the following steps:

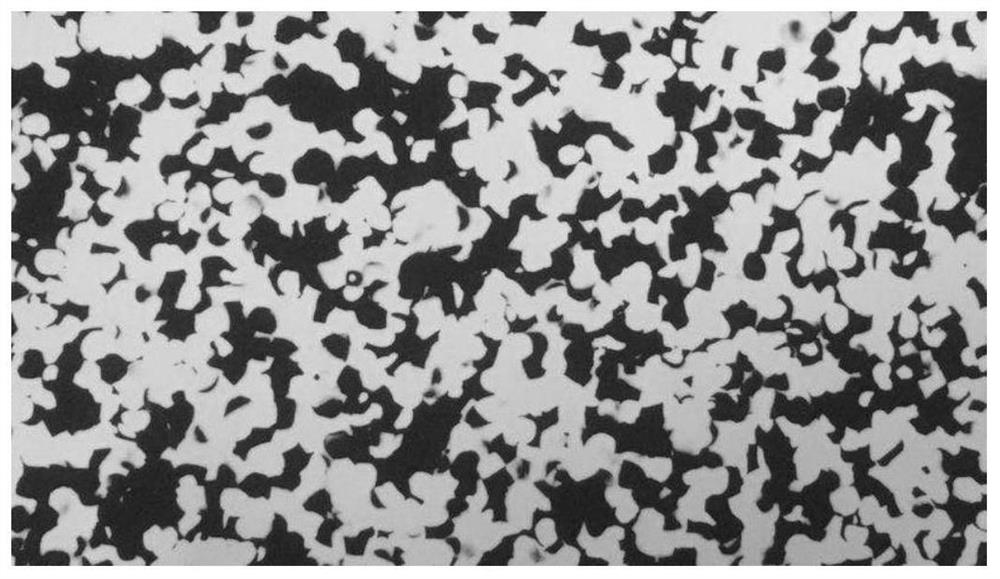

[0028] After mixing the low-hardness rubber compound with the high-hardness rubber compound, vulcanization and foaming are carried out, and the foaming ratio is (1.2-1.3): 1.1 to obtain foamed rubber; the low-hardness rubber compound and the high-hardness The melt index of the compounded rubber is between 2.5-3g / 10min;

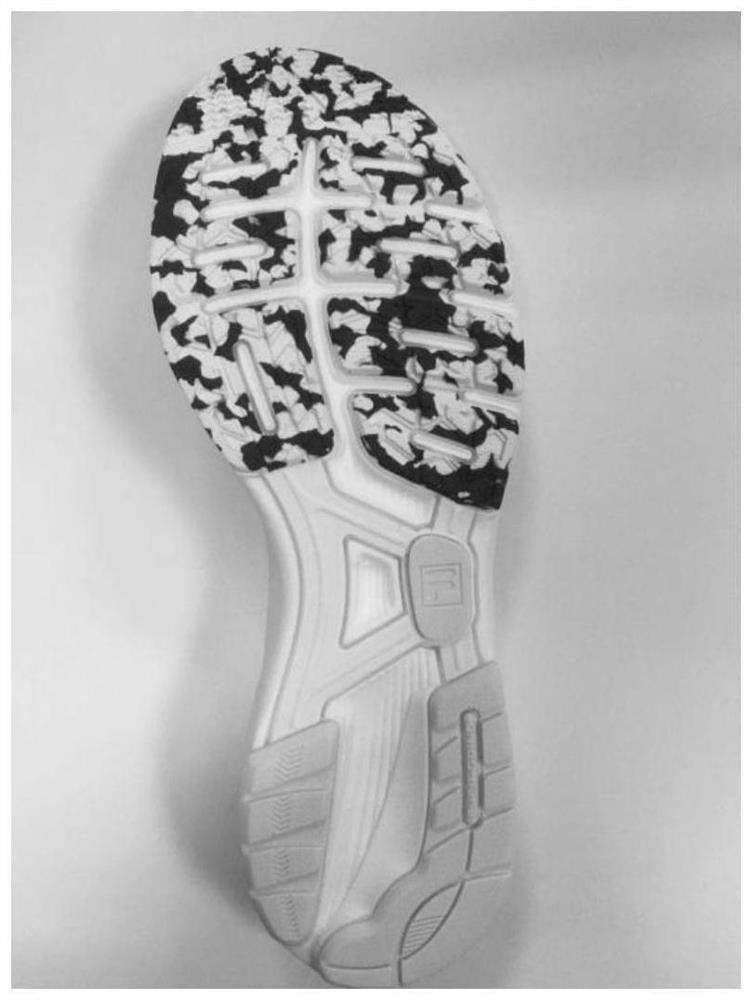

[0029] The foamed rubber is combined with the midsole semi-finished product to obtain a composite responsive foamed rubber and plastic shoe sole.

[0030] The shoe sole prepared by the method of the invention has multiple hardnesses, can adaptively perform different functions under different exercise intensities or road surface environments, and can meet various response requirements in a multi-point bearing manner.

[0031] see figure 1 , figure 1 It is a process flow diagram for preparing shoe soles in so...

Embodiment 1

[0059] Weighing: (1) According to the low-hardness formula, the plastic main materials such as EVA7360M, OBC 9107, SEBS YH506, BIIR X2, BR9000 were weighed as the first group, and stearic acid, zinc stearate, zinc oxide, PIB, Wear-resisting agent is named for the second group; BIBP and foaming agent are named for the third group. (2) According to the high hardness formula, EVA 7470M, POE8003 9107, EPDM 5565, BIIRX2, BR9000 and other plastic main materials are weighed as the fourth group, and stearic acid, zinc stearate, zinc oxide, PIB, wear-resistant agent It is called for the fifth group; BIBP and blowing agent are called for the sixth group. See Table 1 for the specific formulation.

[0060] Mixing: (1) First pour the first group of materials into the internal mixer, and turn on the machine, and pour the second group of materials when the temperature rises to 80-85 degrees; when the temperature rises to 90-95 degrees, pour Add the third group of materials, and pour out th...

Embodiment 2-6

[0068] According to the specific formula in Table 1-2, the preparation was carried out according to the method of Example 1, and the finished shoe soles were respectively obtained.

[0069] The concrete formula of the embodiment of the present invention 1-2 of table 1

[0070]

[0071] The concrete formula of the embodiment of the present invention 3-6 of table 2

[0072]

[0073]

[0074] Wherein, raw material performance, source in the embodiment are as follows:

[0075] EVA 7470M: VA molar content is 26%, hardness 82A, Formosa Plastics Corporation.

[0076] EVA 7360M: VA molar mass content 21%, hardness 86A, Yaju Company.

[0077] Infuse 9107: Hardness 60A, crystallinity 10.6%, melting point 120°C, Dow Chemical.

[0078] Engage 8003: Hardness 60A, crystallinity 10.6%, melting point 120°C, Dow Chemical.

[0079] SEBS YH 503: Hardness 74A, hard segment molar mass content 33%, Baling Petrochemical.

[0080] EPDM 5565: Mooney viscosity 65 [ML(1+4) 125°C], ENB cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com