Primary cooler spraying device

A technology of spraying device and primary cooler, which is applied to chemical instruments and methods, filtration and separation, furnace prevention/removal of fouling, etc. It can solve the problem of increased resistance of primary cooler, blockage of heat exchange tubes of primary cooler, and spraying of washing liquid Unevenness and other problems can be achieved to reduce clogging and facilitate installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

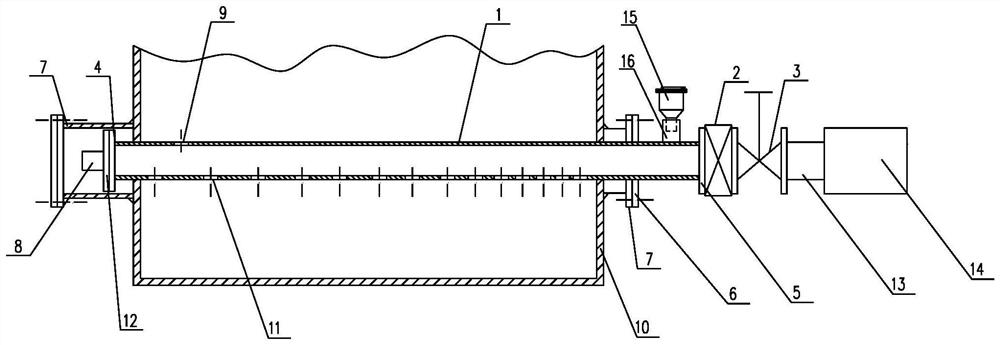

[0022] Such as figure 1 As shown, a primary cooler spraying device includes a spraying pipe 1, a filter 2, an ultrasonic anti-scaling device, a valve 3, a first plate flange 4, a second plate flange 5, and a third plate flange 6 , flange 7, flange cover 12 and short pipe 8.

[0023] The bottom of the spray pipe 1 is provided with a plurality of spray holes 11, and the spray holes 11 are circular holes, oval holes, polygonal holes or holes of irregular shape. From left to right, the spacing of the spraying holes 11 decreases gradually, or the area of the spraying holes 11 gradually increases from left to right, and a small hole 9 is opened on the top of the left end of the spraying pipe 1 . The two flanges 7 are symmetrically fixed on the cylinder body of the primary cooler, the third plate flange 6 is fixed on the right end of the spray pipe 1, the third plate flange 6 and the right end flange 7 are connected by bolts, and then the spraying The pipe 1 is fixed horizontally...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap