Riser pre-buried floor drain of rainwater drainage system

A drainage system and riser technology, applied in waterway systems, water supply devices, roof drainage, etc., can solve problems such as water leakage, cracks in sealing materials, etc., and achieve the effects of enhancing drainage capacity, avoiding flattening, and enhancing the siphon effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

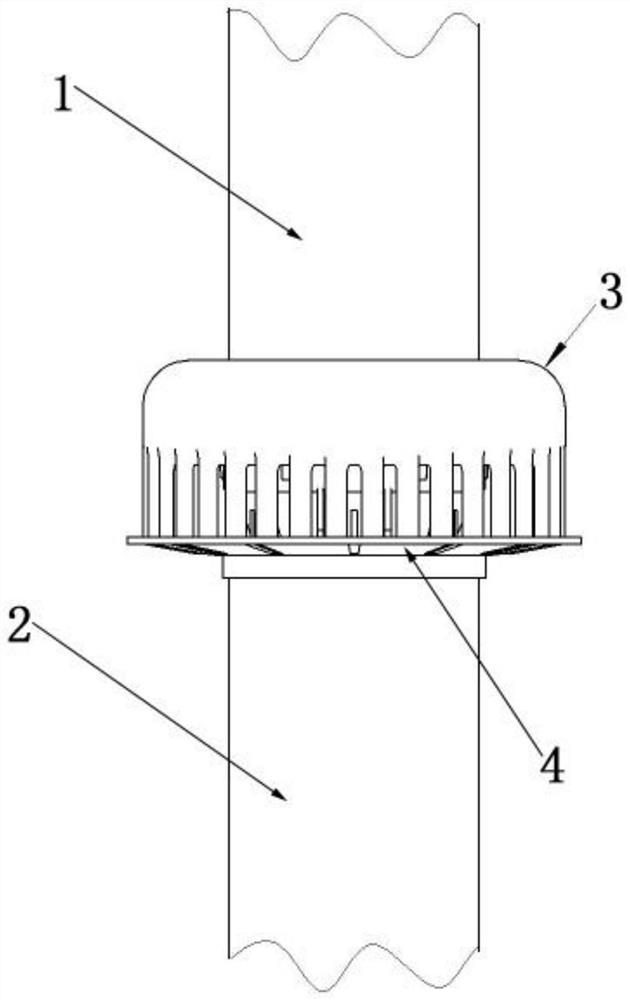

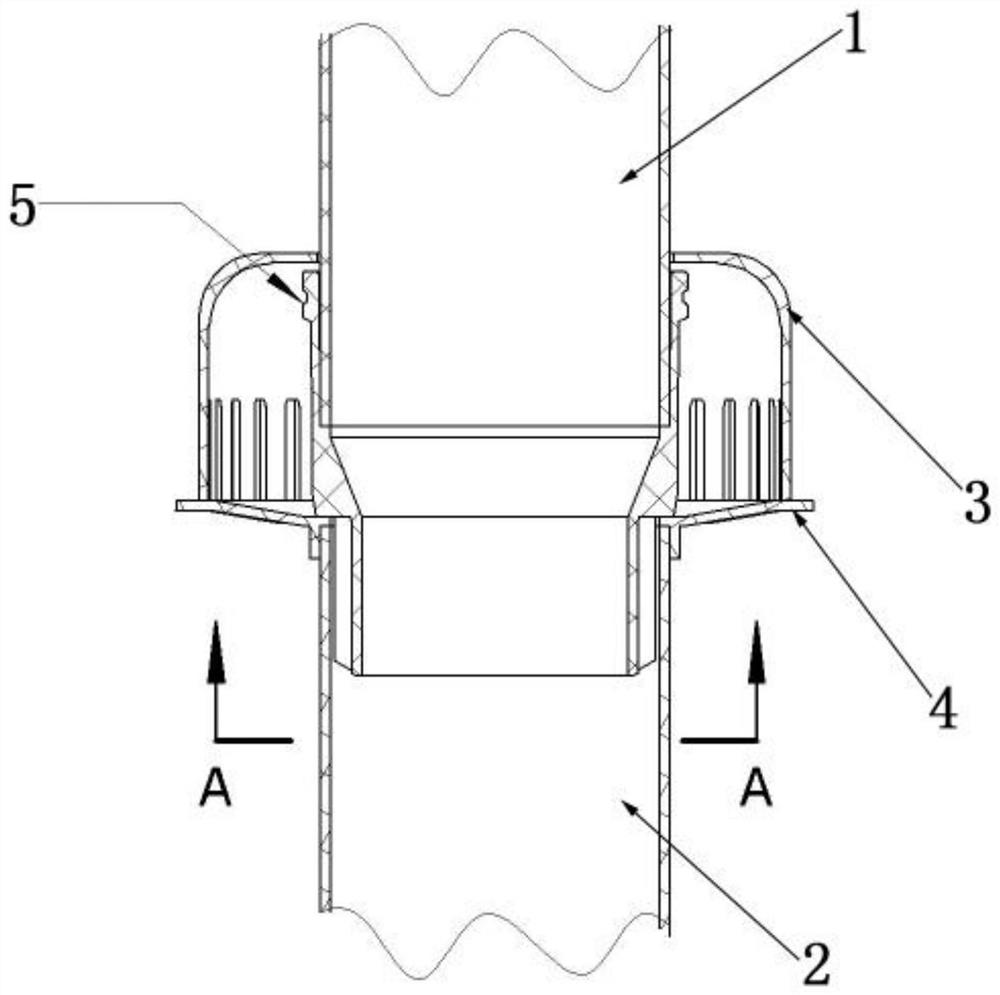

[0024] Example: Control Figure 1-5

[0025] A rainwater drainage system standpipe embedded floor drain, including a protective cover 3, a water collecting tray 4, an upper standpipe 1, a lower standpipe 2, and a main body 5 for connecting the upper standpipe 1 and the lower standpipe 2, the main body 5 includes a large round pipe 51, a reducer and a small round pipe 52 arranged from top to bottom, and the lower end of the upper standpipe 1 is processed with an indentation structure matching the inner space of the main body 5, so that the lower end of the upper standpipe 1 is inserted into the main body within 5.

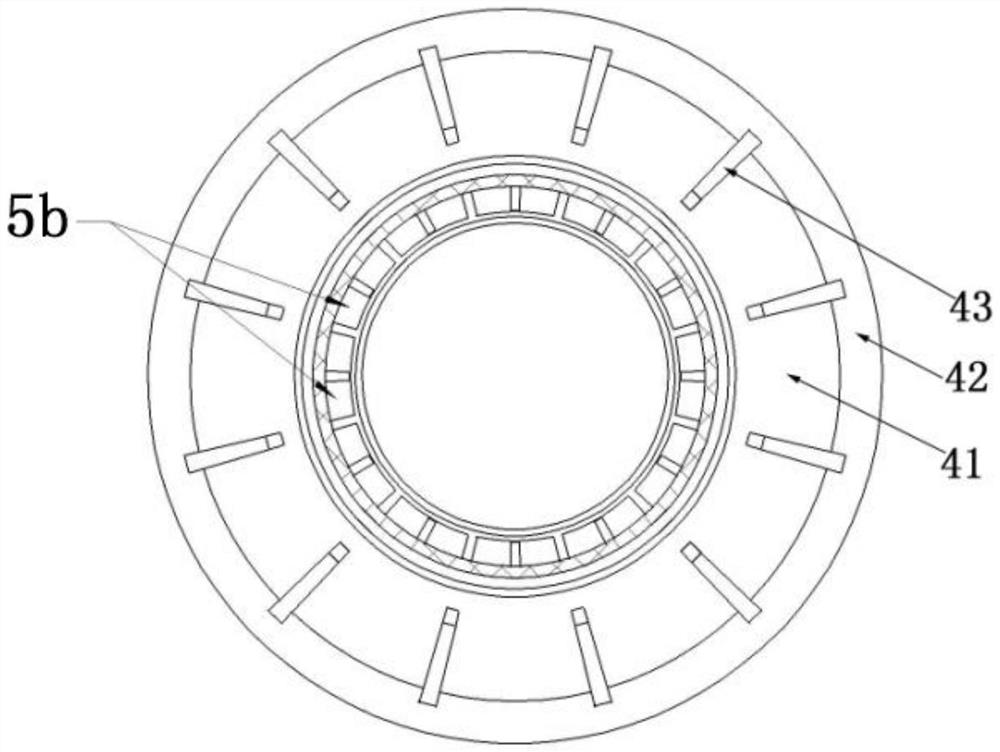

[0026] The outer side of the small round tube 52 is evenly spaced along the circumferential direction with a number of vertical grid plates 5b. When the small round tube 52 is inserted into the lower vertical tube 2, all the grid plates 5b on the outer side of the small round tube 52 are connected to the lower vertical tube. The inner walls of the tubes 2 are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com