A kind of gpf reliability test method of passenger car

A test method and reliability technology, applied in vehicle testing, machine/structural component testing, instrumentation, etc., can solve the problems of GPF durability test, no disclosure of invention points, etc., to ensure test reliability and improve accuracy , the test results are accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] The passenger car vehicle GPF reliability test method in one embodiment provided by the invention comprises the following steps:

[0028] 1) Restructure the GPF system installed on the vehicle, install the temperature sensor on the GPF of the vehicle, monitor the temperature of the GPF and measure the weight of the particles captured by the GPF during the vehicle test, and configure the data acquisition system for the GPF control parameters to monitor the vehicle The state during the test is monitored throughout the process;

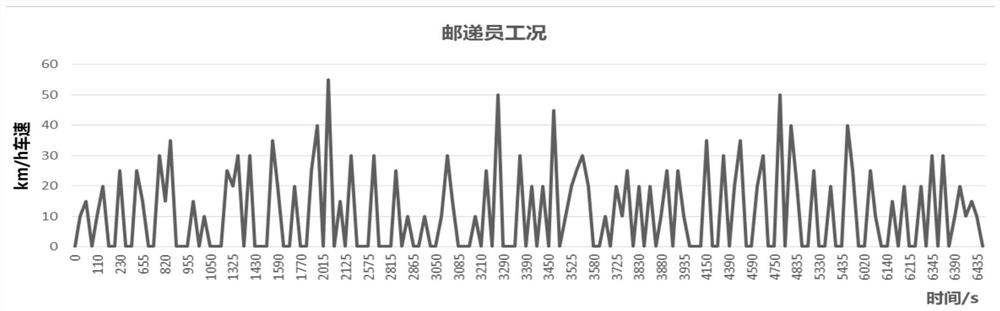

[0029] 2) Investigate the actual operating conditions of the vehicle and road environmental conditions, and find out the worst operating conditions in the actual use of the vehicle for the key factors affecting the reliability of the GPF, and combine them with common operating conditions to compile a complete assessment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com