Mechanical equipment lubricating device

A technology for lubricating devices and mechanical equipment, applied in the direction of mechanical equipment, engine lubrication, lubricating parts, etc., can solve the problem of single way of lubricating oil application, and achieve the effect of diversified oiling methods, convenient and efficient oiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

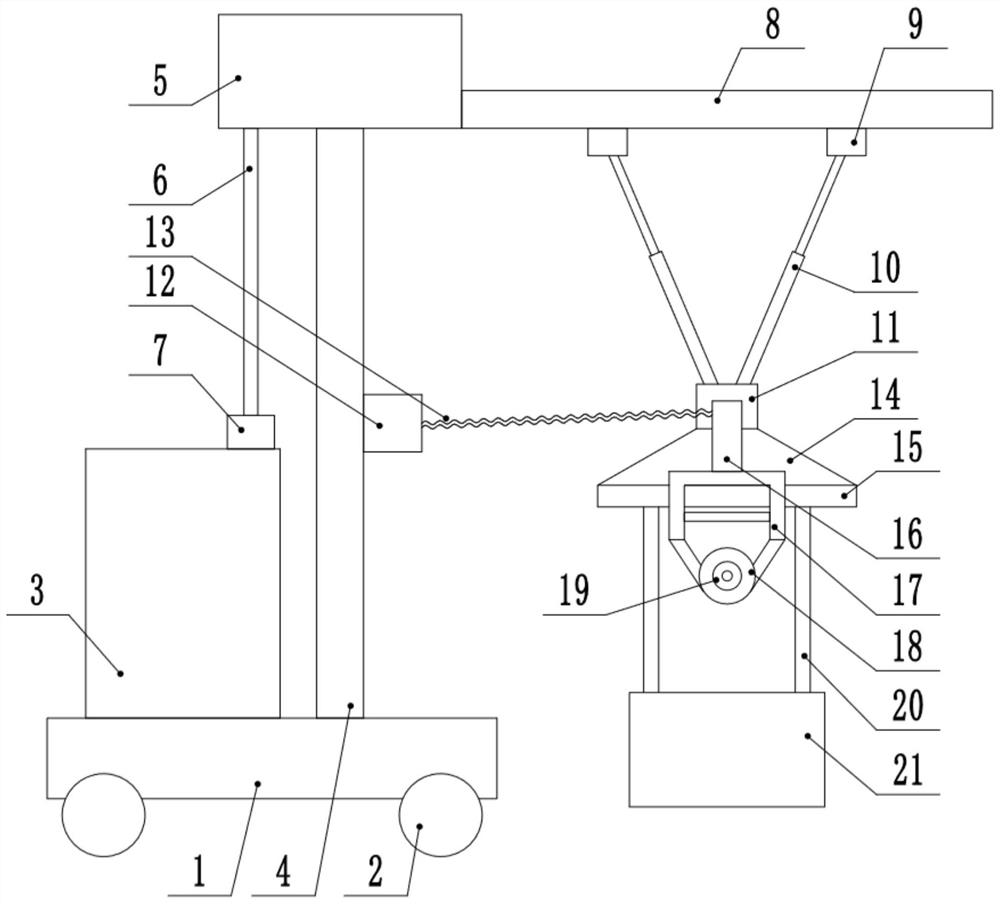

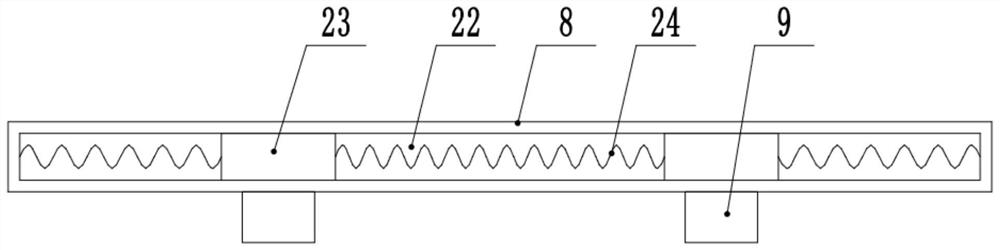

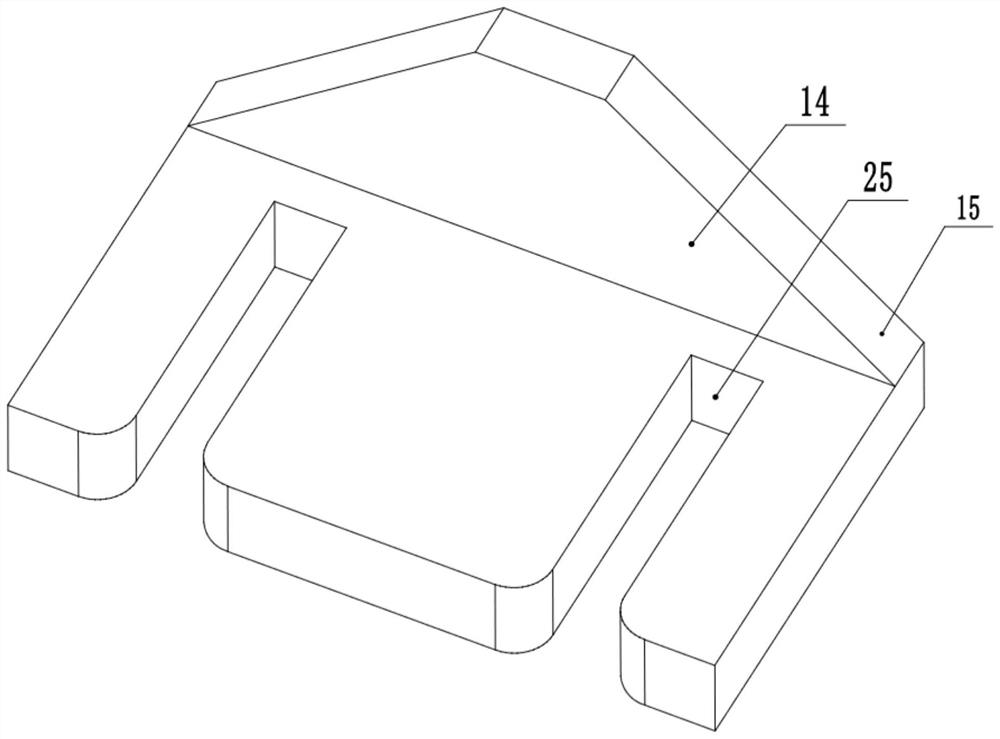

[0022] see Figure 1-4 , a lubricating device for mechanical equipment, comprising a base 1, the four corners of the bottom of the base 1 are provided with moving wheels 2, the top of the base 1 is fixedly connected to a lubricating oil tank 3, the top of the base 1 is fixedly connected to a column 4, and the top of the column 4 is fixedly connected to The transfer box 5 and the top of the lubricating oil tank 3 are fixedly connected to the delivery pump 7, the output end of the delivery pump 7 is fixedly connected to the delivery pipe 6, the delivery pipe 6 is fixedly connected to the transfer box 5, and one end of the transfer box 5 is fixedly connected to the cross bar 8 Cross bar 8 A follow-up buffer adjustment mechanism is provided inside, and the follow-up buffer adjustment mechanism connects two first telescopic rods 10, the bottom end of the first telescopic rod 10 is connected to the first connecting seat 11 in rotation, and the bottom end of the first connection is fi...

Embodiment 2

[0028] see Figure 1-4 , a lubricating device for mechanical equipment, comprising a base 1, the four corners of the bottom of the base 1 are provided with moving wheels 2, the top of the base 1 is fixedly connected to a lubricating oil tank 3, the top of the base 1 is fixedly connected to a column 4, and the top of the column 4 is fixedly connected to The transfer box 5 and the top of the lubricating oil tank 3 are fixedly connected to the delivery pump 7, the output end of the delivery pump 7 is fixedly connected to the delivery pipe 6, the delivery pipe 6 is fixedly connected to the transfer box 5, and one end of the transfer box 5 is fixedly connected to the cross bar 8 Cross bar 8 A follow-up buffer adjustment mechanism is provided inside, and the follow-up buffer adjustment mechanism connects two first telescopic rods 10, the bottom end of the first telescopic rod 10 is connected to the first connecting seat 11 in rotation, and the bottom end of the first connection is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com