A chip cleaning device and cleaning method

A chip cleaning and chip technology, used in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of a large number of bumps on the chip surface, damage, and small size, and achieve semi-automatic cleaning. , Improve cleaning efficiency and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

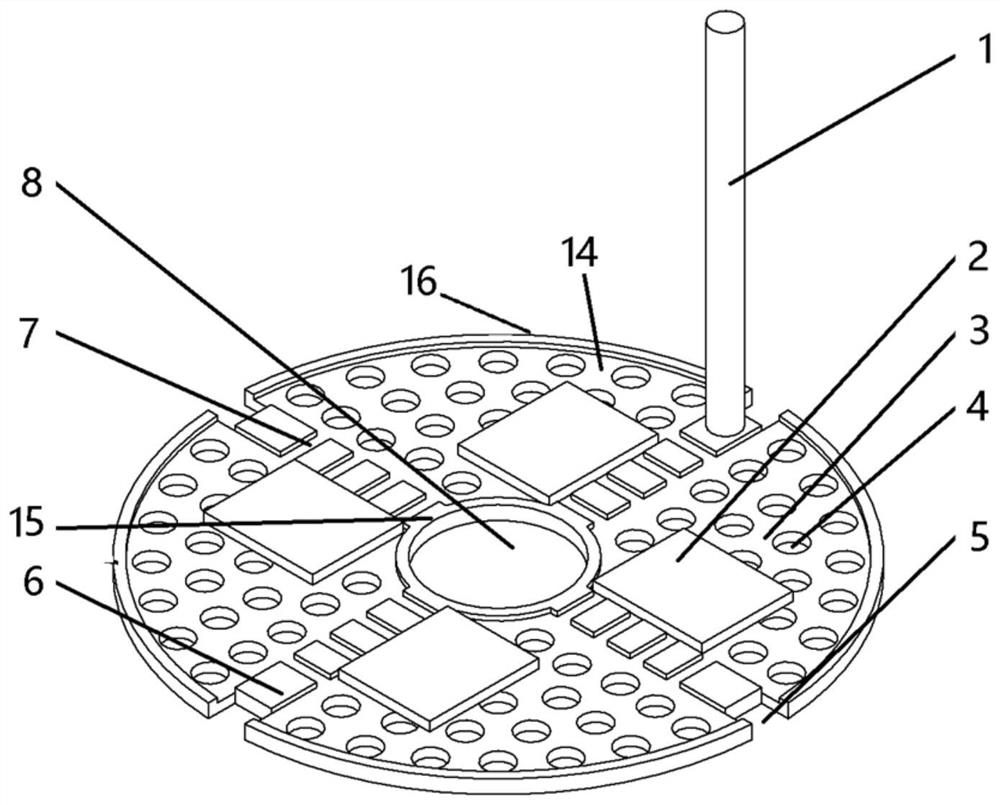

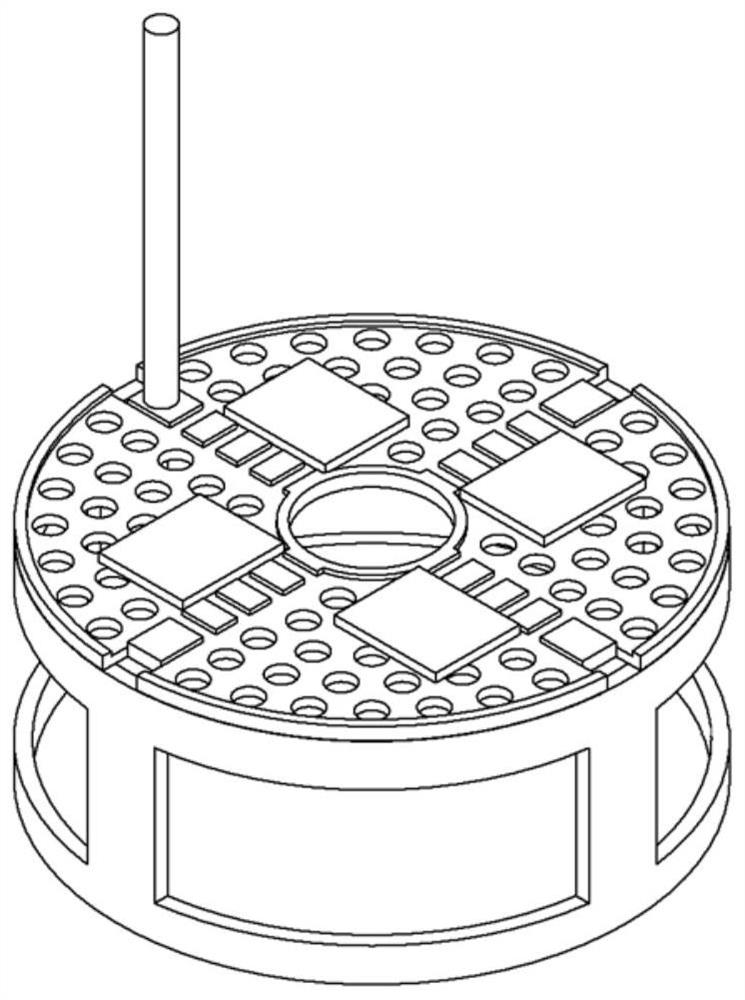

[0045] see figure 1 , the carrying portion in the present embodiment is a carrying plate 14, and the bottom wall of the carrying plate 14 is evenly distributed with a plurality of circular through-holes 4 to allow the solvent to flow up and down, and a guide hole 8 is provided in the center of the carrying plate 14, The outer edge of the guide hole 8 is provided with a guide hole boss 15 that is higher than the bottom wall of the carrier tray 14 , and the outer edge of the carrier tray 14 is provided with a carrier tray boss 16 . Wherein, the isolation part includes four isolation strips 6 arranged on the carrier plate 14 , one end of each isolation band 6 is connected to the boss 15 of the flow guide hole, and the other end extends to the outer edge of the carrier plate 14 . The four isolation strips 6 are distributed on the carrier tray 14 in a diverging shape, and divide the carrier tray 14 into four cleaning units 3 with fan-shaped structures. By placing each chip 2 in an...

Embodiment 2

[0051] The structure of the chip cleaning device in this embodiment is basically the same as that in Embodiment 1, the difference is that the stirrer in this embodiment is a mechanical stirrer with stirring paddles arranged above the carrying plate, and the fluid acts on the stirring paddles Down, the rotating flow conducts from top to bottom. It is not necessary to set up diversion holes on the carrier plate, and at the same time, it is also possible to place the carrier plate directly on the bottom of the container filled with solvent to meet the requirements of the solvent in the rotating flow state. Technical requirements for scour cleaning.

[0052] The present invention also provides a method for cleaning chips implemented by the above-mentioned chip cleaning device. Specifically, the cleaning of chips is explained in the form of a magnetic stirrer in Example 1:

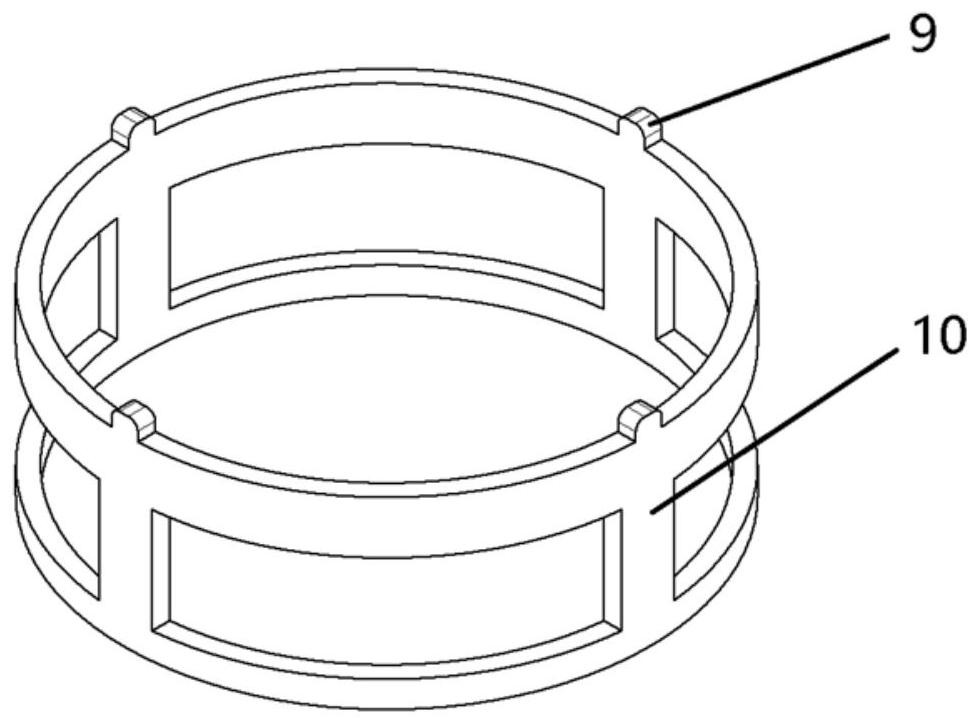

[0053] see Figure 5a-5c , and combined with figure 1 , first place the support 10 and the rotating magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com