Rapid assembling device for three-section type through-wall water stop bolt

A technology of water-stop bolts and assembly devices, which is applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of unstable assembly quality, long time-consuming, low efficiency, etc., and achieve improved installation stability and reliability , easy to operate, and good technical prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

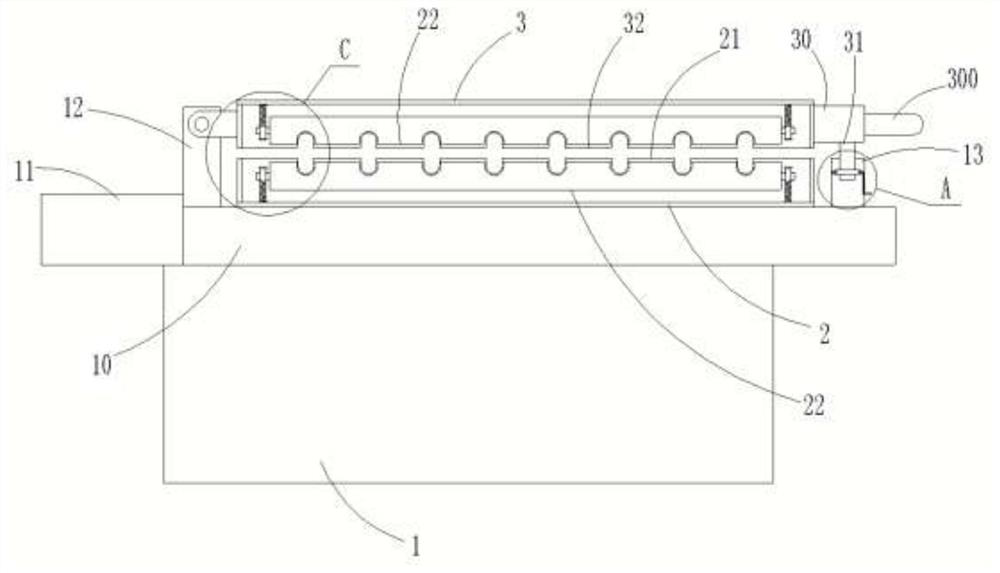

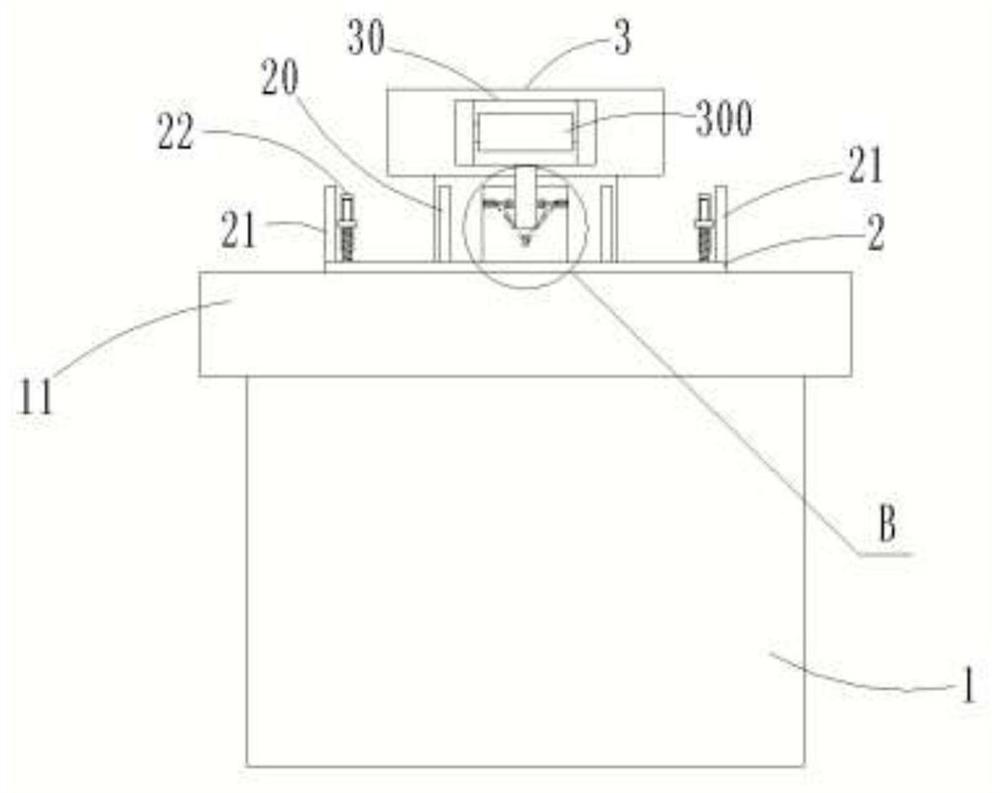

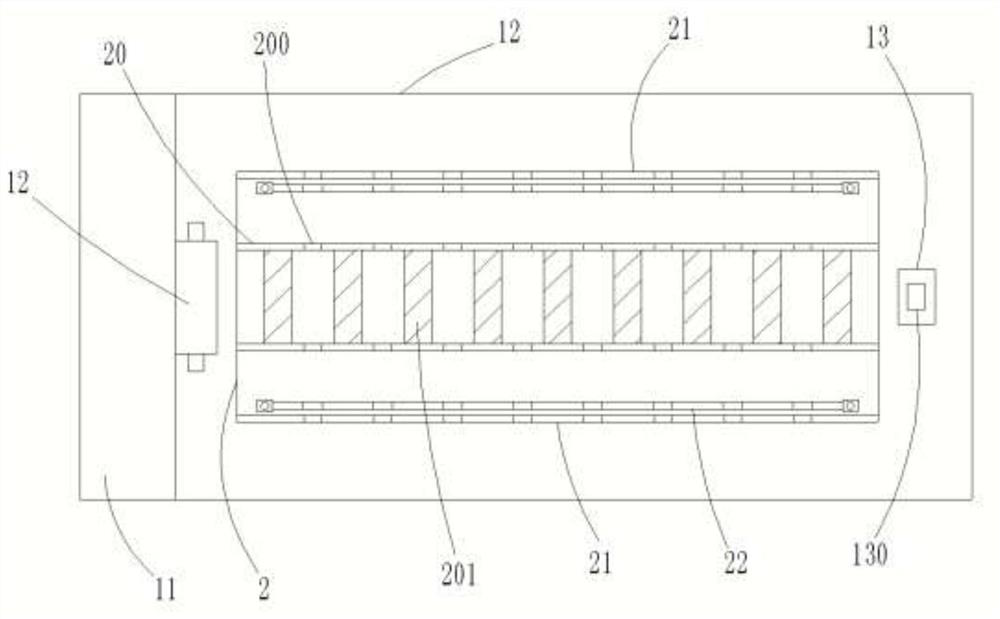

[0022] Example: such as figure 1 , 2 , 3, 4, and 5 show a three-stage fast assembly device for water-stop bolts through walls, including a base box 1, a fixed base plate 2 and a pressure plate 3; the upper end of the base box 1 is horizontally arranged with an installation console 10 and a tool table 11. One end of the installation console 10 is fixedly provided with a mounting base 12, and the other end is fixedly provided with a socket 13. The socket 13 is provided with a socket 130, and the inside of the socket 13 is provided with a locking assembly 14. The locking assembly 14 includes a locking roller 140 and an unlocking slide bar 141. There are two locking rollers 140, and the ends of the two locking rollers 140 are all rotated to be provided with a spring reset lever 142. The locking roller 140 connects with the plug-in Both sides of the socket 13 are connected, and the two spring return levers 142 are provided with a hinge block 1420, the hinge block 1420 runs through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com