Hard sealing clamping and pressing pipe fitting

A technology of hard sealing and pipe fittings, applied in the direction of pipes/pipe joints/fittings, through components, sleeves/sockets, etc., it can solve problems such as not very good, easy to drop and lose sealing effect, small size of seals, etc., to achieve Effect of improving connection strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

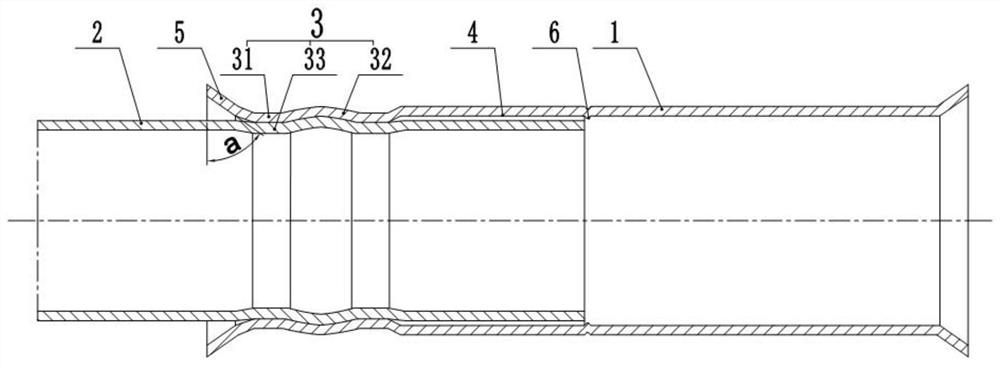

[0021] refer to figure 1 , this embodiment provides a hard-sealed clamping pipe fitting, including a pipe fitting 1, the pipe fitting 1 is a thin-walled metal pipe fitting, the pipe fitting 1 can be a two-way pipe fitting, a three-way pipe fitting or a multi-way pipe fitting, and each end of the pipe fitting 1 is socketed The supporting pipe 2 is connected, and the inside of the pipe fitting 1 is fixedly provided with a limit protrusion 6, which contacts with the end of the supporting pipe, and the length of the supporting pipe 2 inserted into the pipe fitting 1 is limited by the limit protrusion 6. The end of each pipe fitting 1 is a socket 5, the socket 5 is bell-shaped, the length of the socket 5 is 2mm-6mm, and the angle a between the socket 5 and the end surface of the socket 5 is 30°-60° °. A clamping area 3 and a rigid fit area 4 are provided between the pipe fitting 1 and the matching pipe material 2 .

[0022] The crimping area 3 is arranged on the side close to the...

Embodiment 2

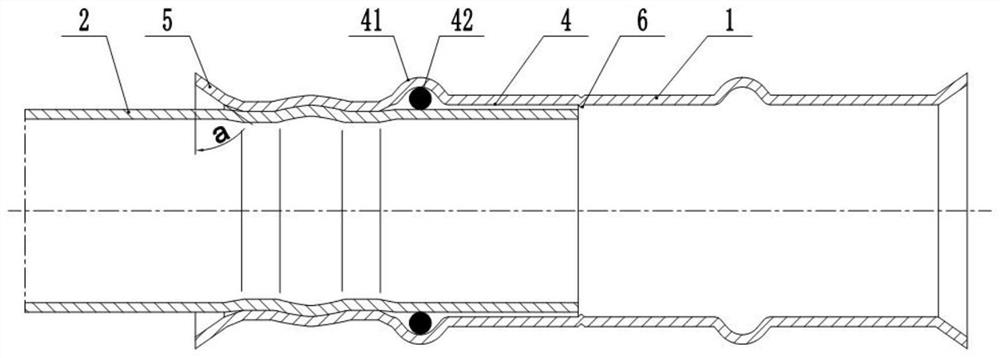

[0026] refer to figure 2 , this embodiment provides a hard-sealed clamping pipe fitting. The difference between this embodiment and Embodiment 1 is that the rigid fitting area 4 includes a sealing ring convex groove 41 arranged on the pipe fitting 1, and the sealing ring convex groove 41 is provided with A sealing ring 42 matching with the convex groove 41 of the sealing ring. The convex groove 41 of the sealing ring is an O-ring convex groove, which increases the sealing effect and can be used for medium sealing such as compressed gas medium and high-pressure refrigerant.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap