Accurate small-sized friction-free multifunctional valve

A multi-functional valve, frictionless technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of long opening and closing time of stop valves and throttle valves, and achieve light weight, reliable cut-off, and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

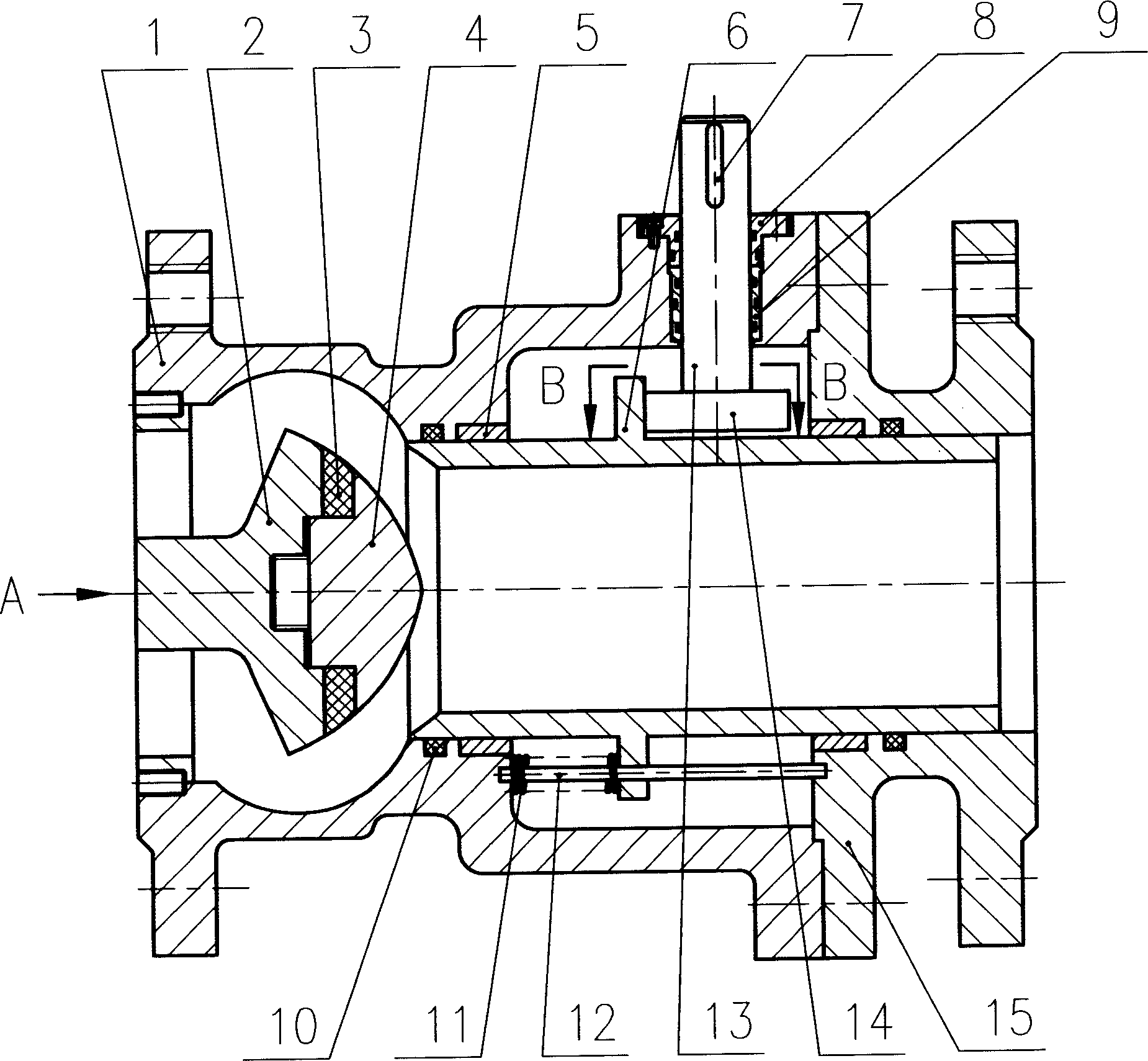

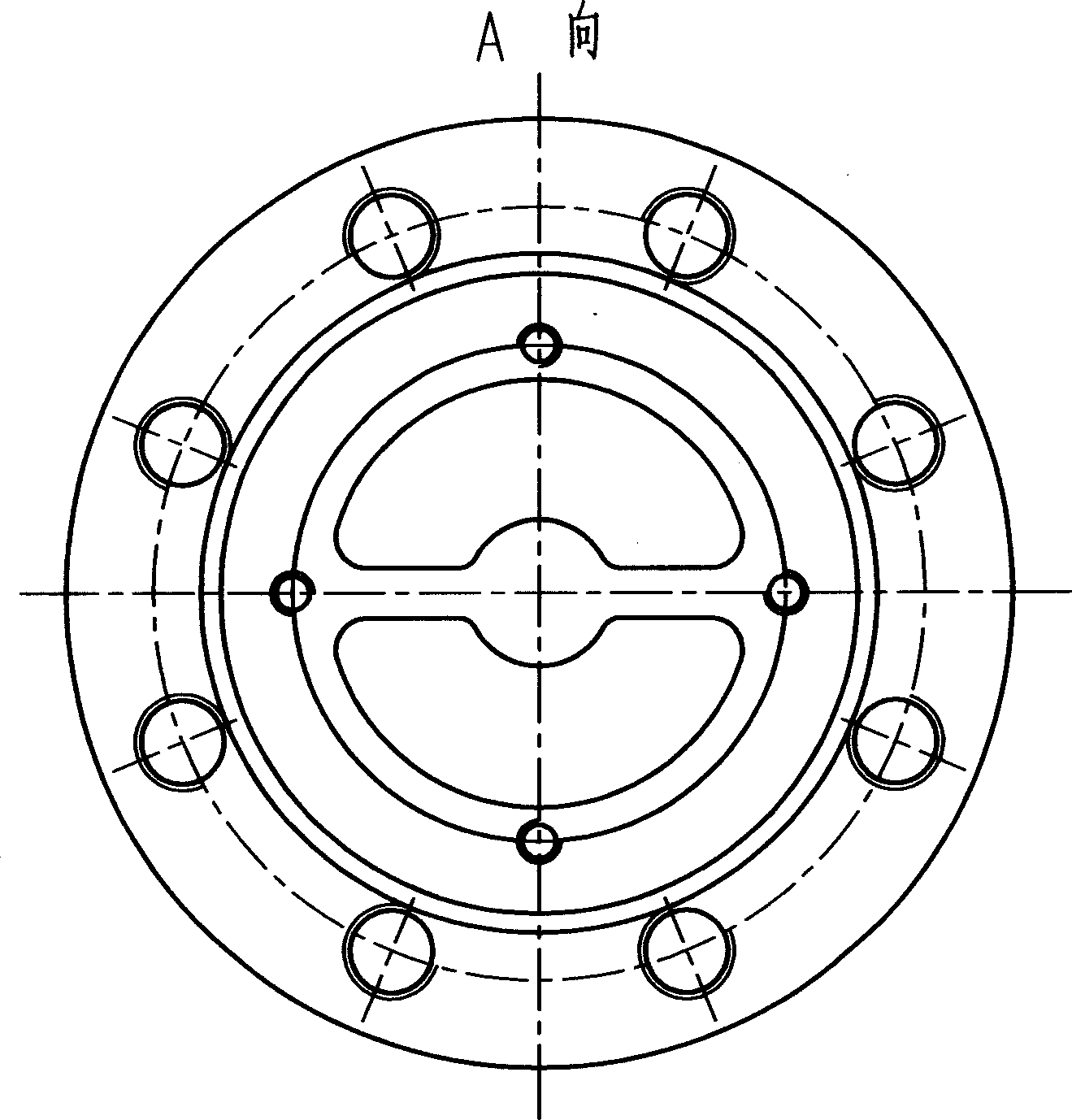

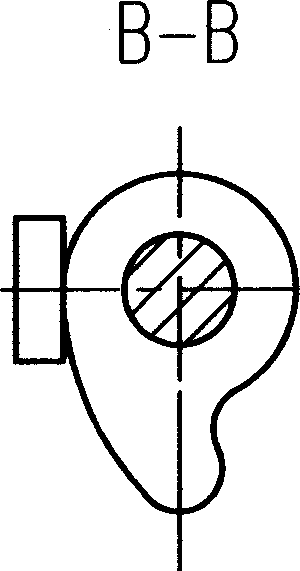

[0011] Such as figure 1 As shown, the valve seat (2) is installed at the left end of the valve body (1). ), the pressure plate (4) and the valve seat (2) are threadedly connected, the valve core (6) is supported in the passage between the valve body (1) and the valve cover (15) through the bushing (5), and the valve core (6) It is sealed with the valve body (1) and the valve cover (15) by an O-ring (10), and a spring (11) is installed between the inner cavity step of the valve body (1) and the boss of the valve core (6), The spring (11) is limited by the guide rod (12), and the guide rod (12) passes through the boss of the valve core (6) and is respectively inserted into the corresponding holes of the valve body (1) and the valve cover (15). In addition to the limit of the spring (11), it also plays a role in preventing the rotation of the valve core (6). The valve stem (13) and the cam (14) are fixedly connected by screws, and can also be welded as one. The valve stem (13) a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap