An Intermittent Hard Sealed Zero-Friction Butterfly Valve

A hard-sealed, zero-friction technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of high cost, high manufacturing and installation accuracy, and achieve good sealing, lower manufacturing accuracy, and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof, but it does not limit the claims of the present invention.

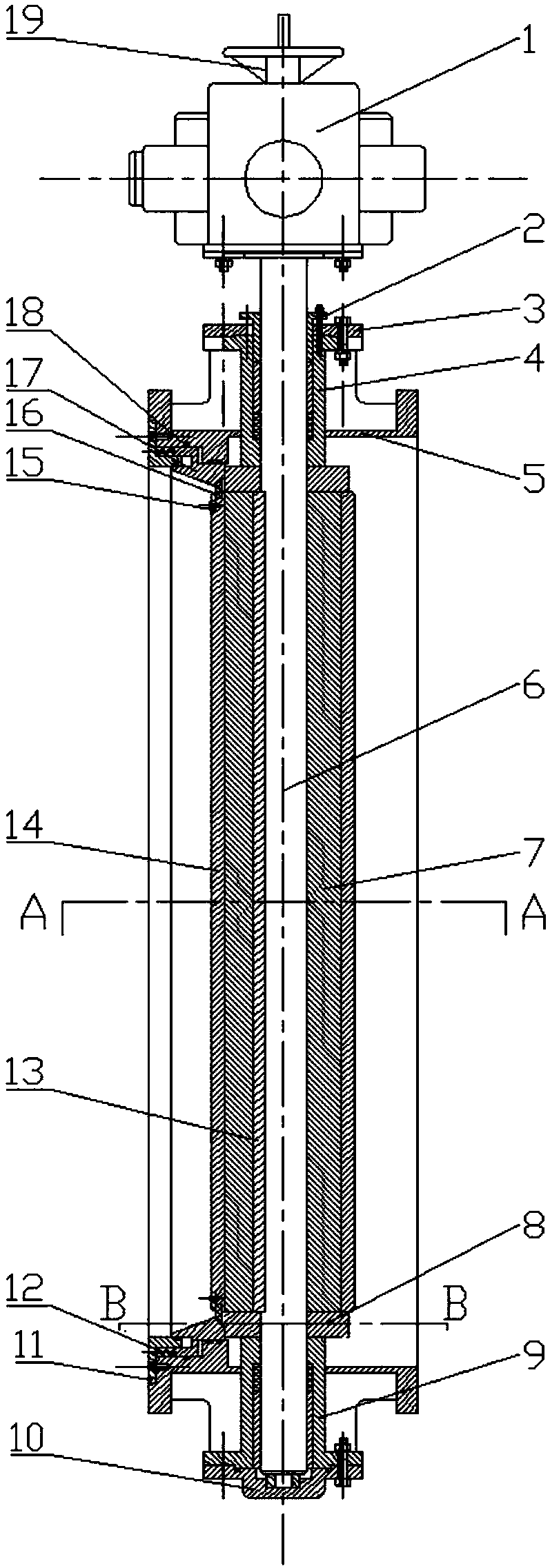

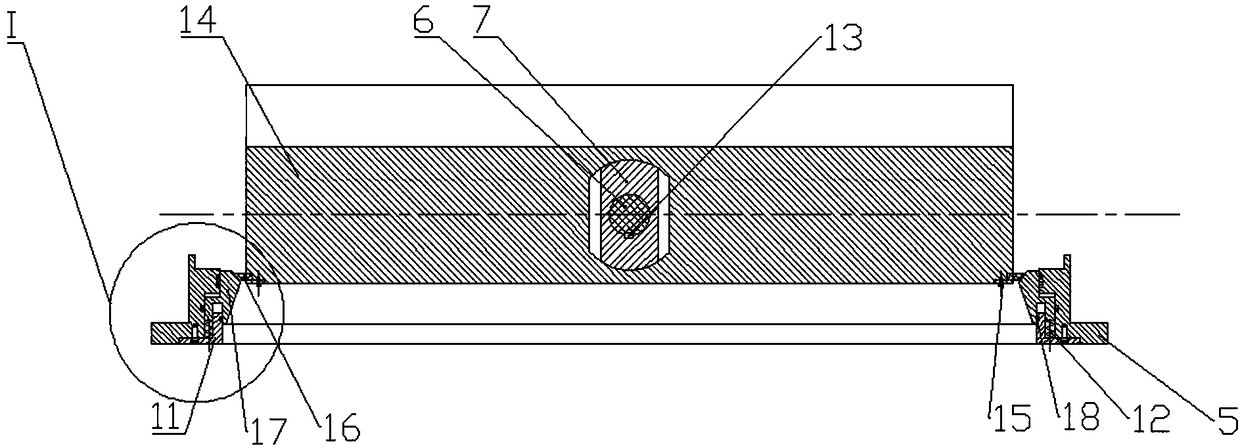

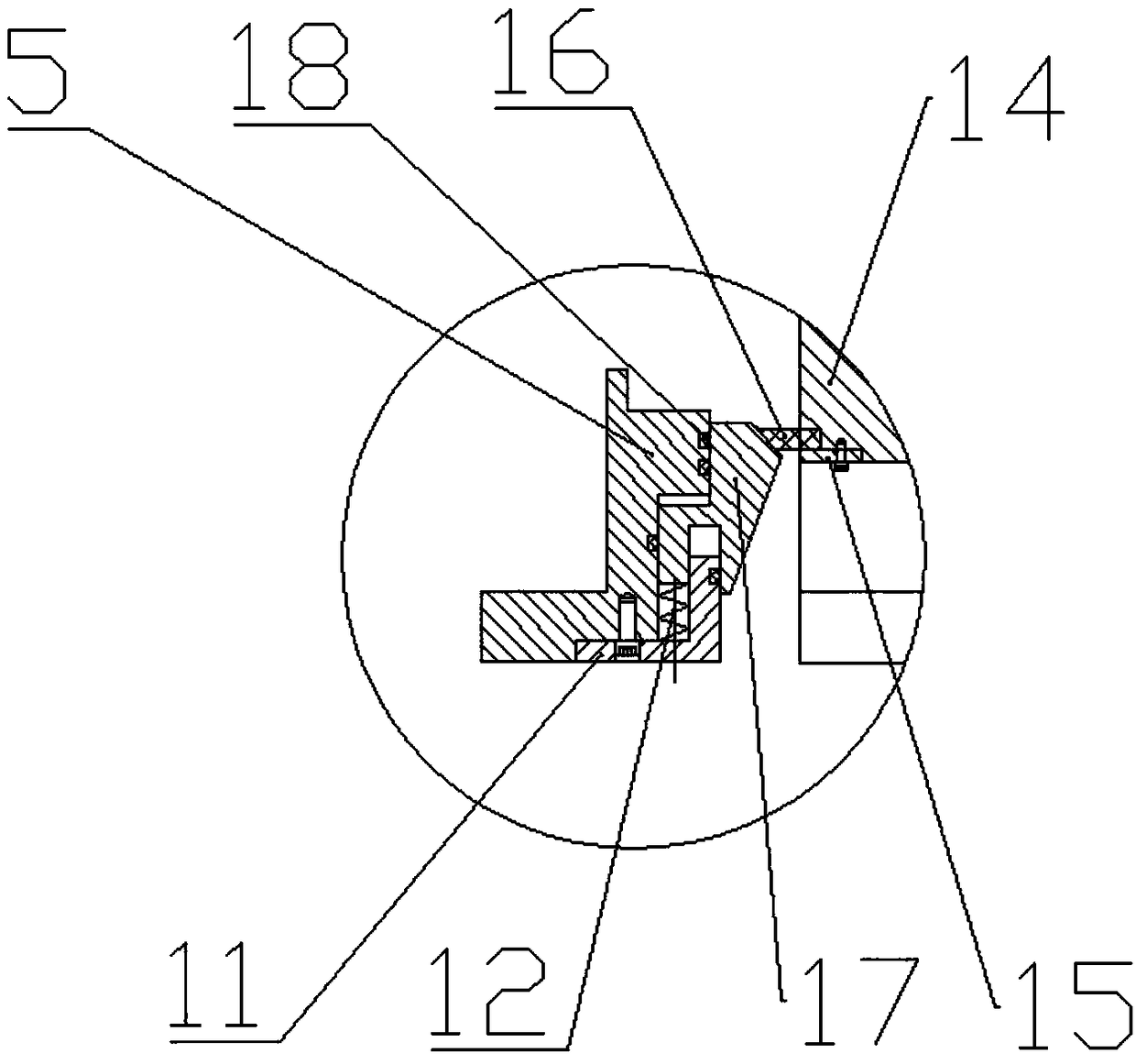

[0019] The intermittent hard-sealed zero-friction butterfly valve of the present invention (referred to as butterfly valve, see Figure 1-6 ) includes a driving device 1, a gland 2, a lower cover 10, a valve body 5, a valve stem 6, a butterfly plate 14 and a movable valve seat 17, the driving device 1 is provided with a handwheel 19, and the valve stem 6 passes through the valve body 5 , the upper and lower ends of the valve body 5 are equipped with a gland 2 and a lower cover 10, the upper end of the valve stem passes through the gland 2 and is connected to the drive device 1, and the lower part of the valve stem passes through the butterfly plate 14; the movable valve seat 17 can be The ring-shaped structure that moves axially along the inner wall of the valve body 5 is set in the valve body 5. The f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap