Assembly type soft and hard package metal hanging piece mounting structure

An installation structure, soft and hard package technology, applied in the field of architectural decoration engineering, can solve the problems of low efficiency of soft and hard package, consume a lot of manpower, affect the construction progress, etc., to reduce the time of repeated glue brushing, facilitate installation and disassembly, reduce The effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

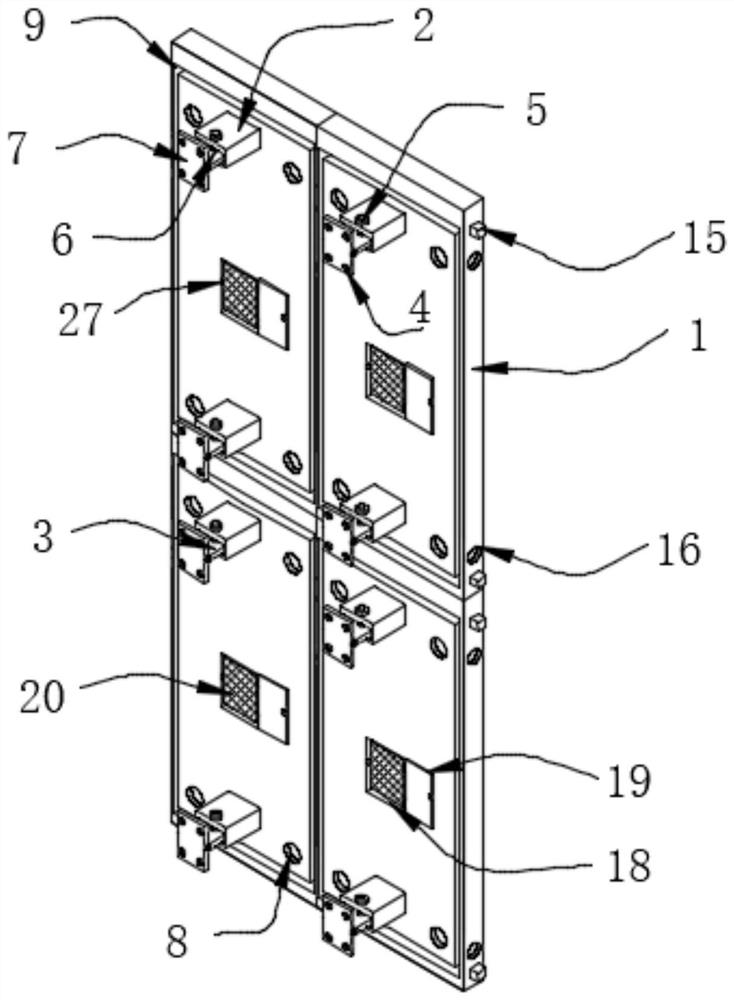

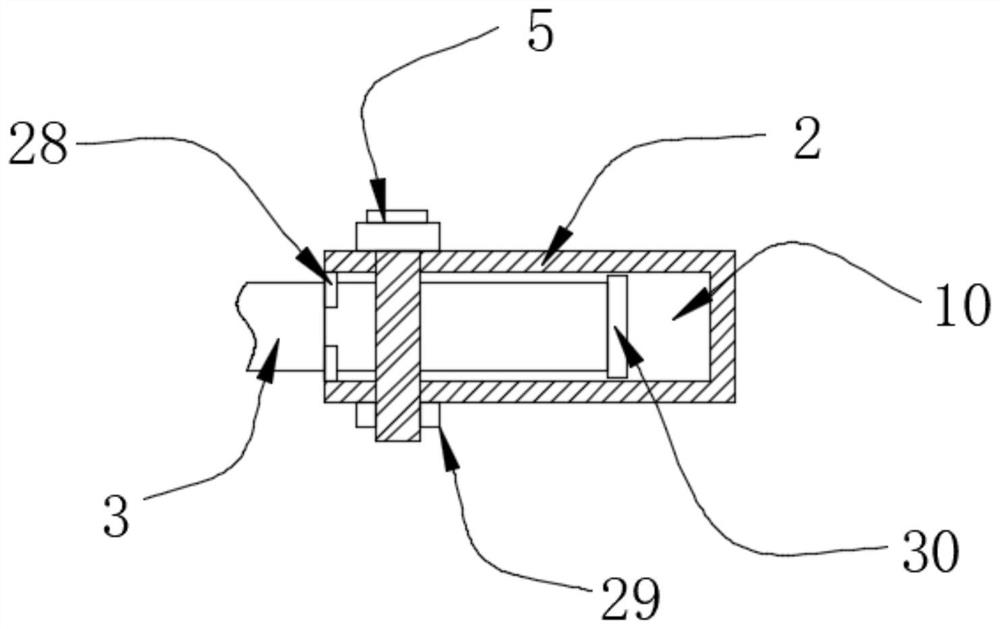

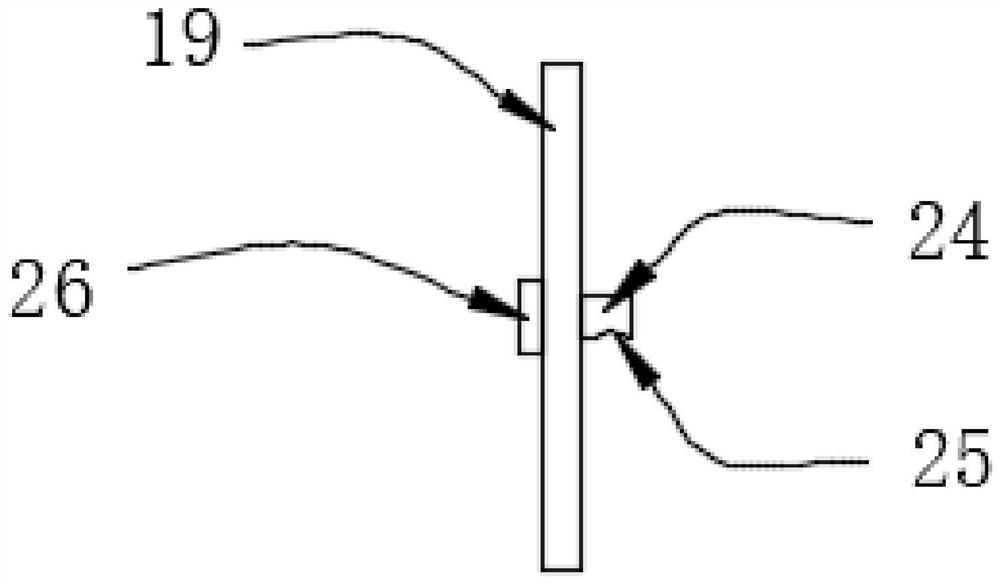

[0030]SeeFigure 1-6, The present invention provides a technical solution: a modular soft and hard clad metal pendant installation structure, comprising a first plate body 1, the front surface of the first plate body 1 is symmetrically fixedly connected with two first fixing blocks 2, the first The inner side wall of the fixed block 2 is provided with a sliding groove 10, the inner side wall of the sliding groove 10 is slidably connected with a first connecting plate 3, and the inner side wall of the first connecting plate 3 is evenly provided with second threaded through holes 6, a second threaded through The inner wall of the hole 6 is screwed with a first bolt 5, one end of the first bolt 5 penetrates the outer wall of the first fixing block 2, and the outer wall of the first bolt 5 is screwed with a nut 29. The front surface of the first connecting plate 3 A second connecting plate 7 is hingedly connected. The inner side wall of the second connecting plate 7 is symmetrically prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com