Method for processing substrates with process gas

A process gas and substrate technology, applied in post-processing, chemical instruments and methods, crystal growth, etc., can solve the problems of reduced productivity, uneven doping, and reduced number of wafers, achieving high productivity, good processing uniformity, The effect of making up for unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An embodiment of the present invention provides a method for doping a wafer with phosphorus oxychloride, which includes:

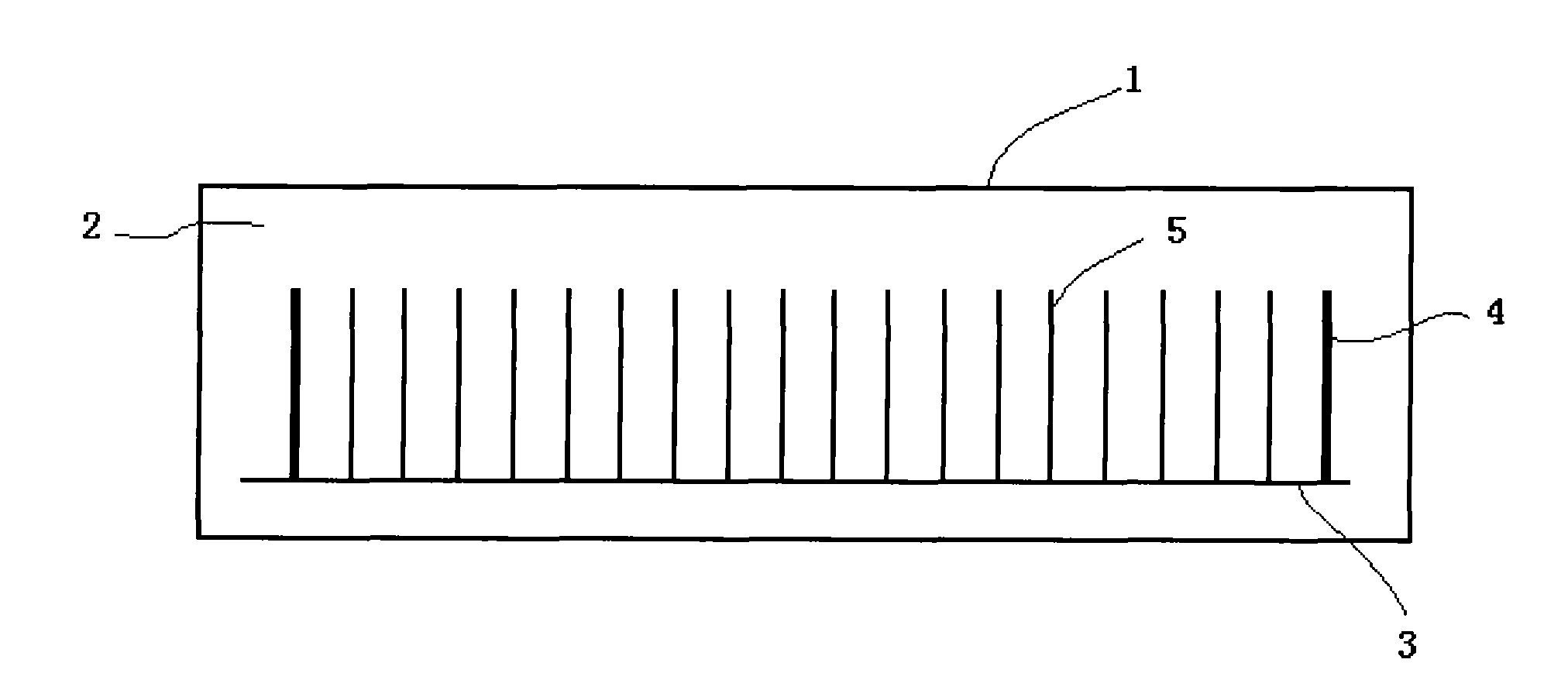

[0025] Step 1. At the standby temperature of 700°C, slowly move the quartz boat containing multiple wafers with a diameter of 6 inches into the chamber of the furnace tube. The wafers are arranged in a row opposite to each other on the upper surface of the quartz boat. The distance between the adjacent wafers is 4.76 millimeters, and a stopper is respectively set at the two ends of a row of wafers, and the distance between the stopper and the adjacent wafer is also 4.76 millimeters (the stoppers are set in this way to ensure that the wafers at the end of the row The outer surface of the wafer gets a uniform treatment).

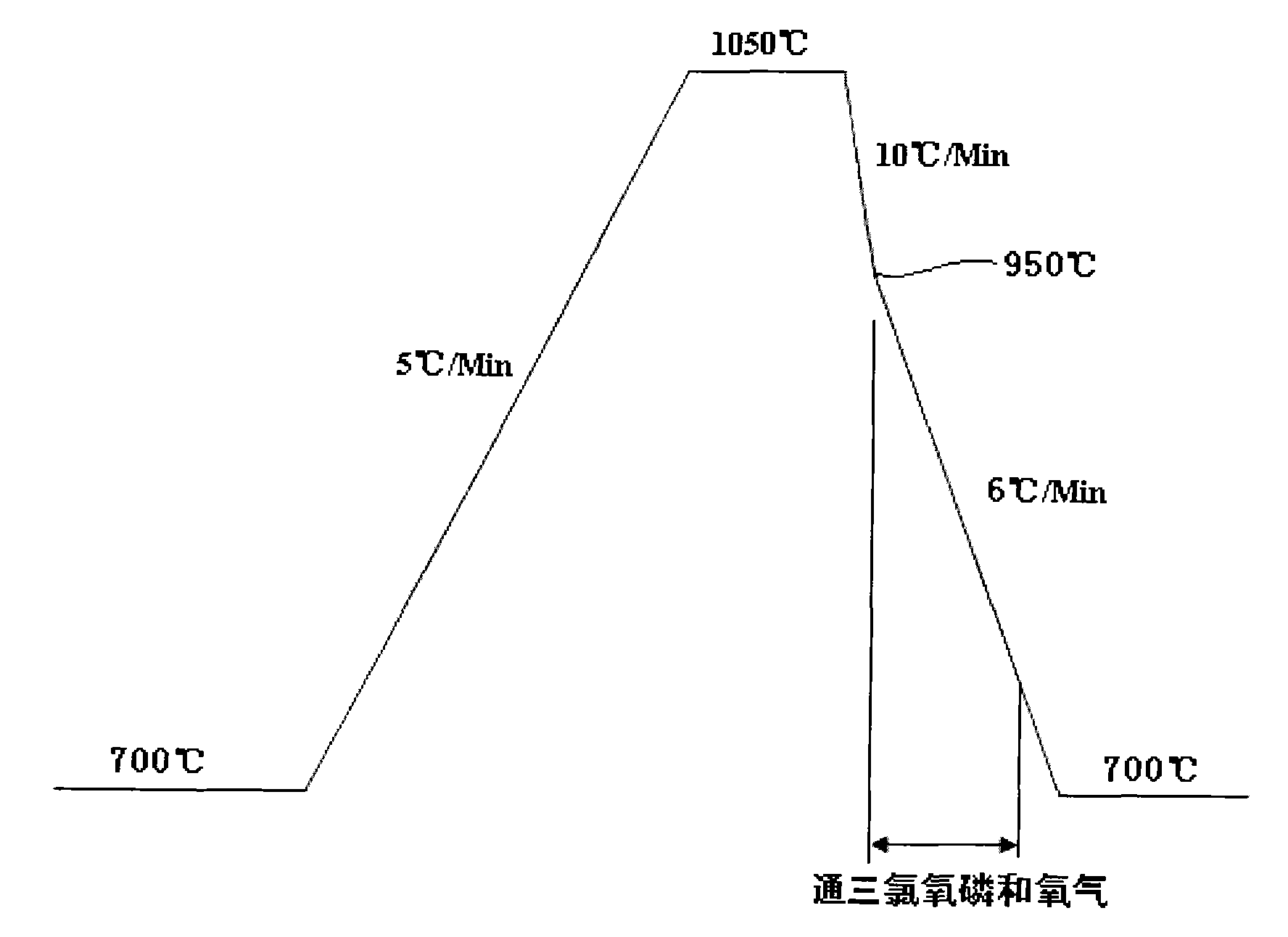

[0026] Step 2. Heat the chamber of the furnace tube to 1050° C. at a heating rate of 5° C. / min.

[0027] Step 3, keeping the temperature at 1050° C. for 20 minutes to make the temperature of each part of each wafer uniform.

[002...

Embodiment 2

[0032] An embodiment of the present invention provides a method for growing polysilicon on a semiconductor substrate with silane gas, comprising:

[0033] Step 1. Slowly move the quartz boat containing multiple semiconductor substrates into the chamber of the furnace tube at a standby temperature of 600°C. The arrangement of the substrates is the same as that of the wafers in Embodiment 1.

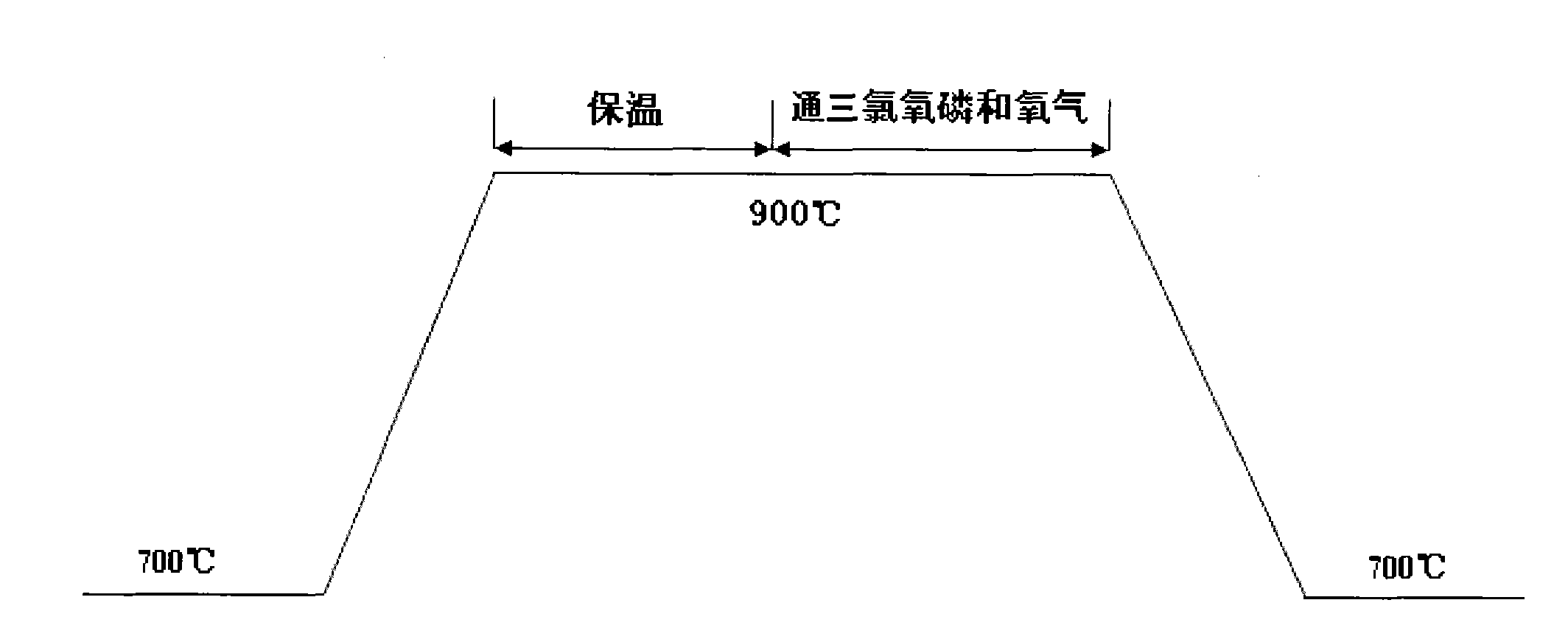

[0034] Step 2. Heat the chamber of the furnace tube to 900° C. at a heating rate of 6° C. / min.

[0035] Step 3, keeping the temperature at 900° C. for 20 minutes, so that the temperature of each part of each semiconductor substrate is uniform.

[0036] Step 4, cooling the chamber to 700° C. at a cooling rate of 8° C. / min, so that the temperature in the middle of the semiconductor substrate is higher than that in the peripheral portion.

[0037] Step 5. When the temperature of the chamber is lowered to 700°C, feed silane into the chamber and start to cool the chamber at a cooling rate of 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com