Contrapositioning applying device

A laminating device and laminating board technology, applied in lamination devices, layered products, lamination, etc., can solve problems such as difficult glass substrates, rough and uneven bonding surfaces, dual-view display or 3D display offset, etc. Achieve the effect of facilitating process development and making up for the effect of unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

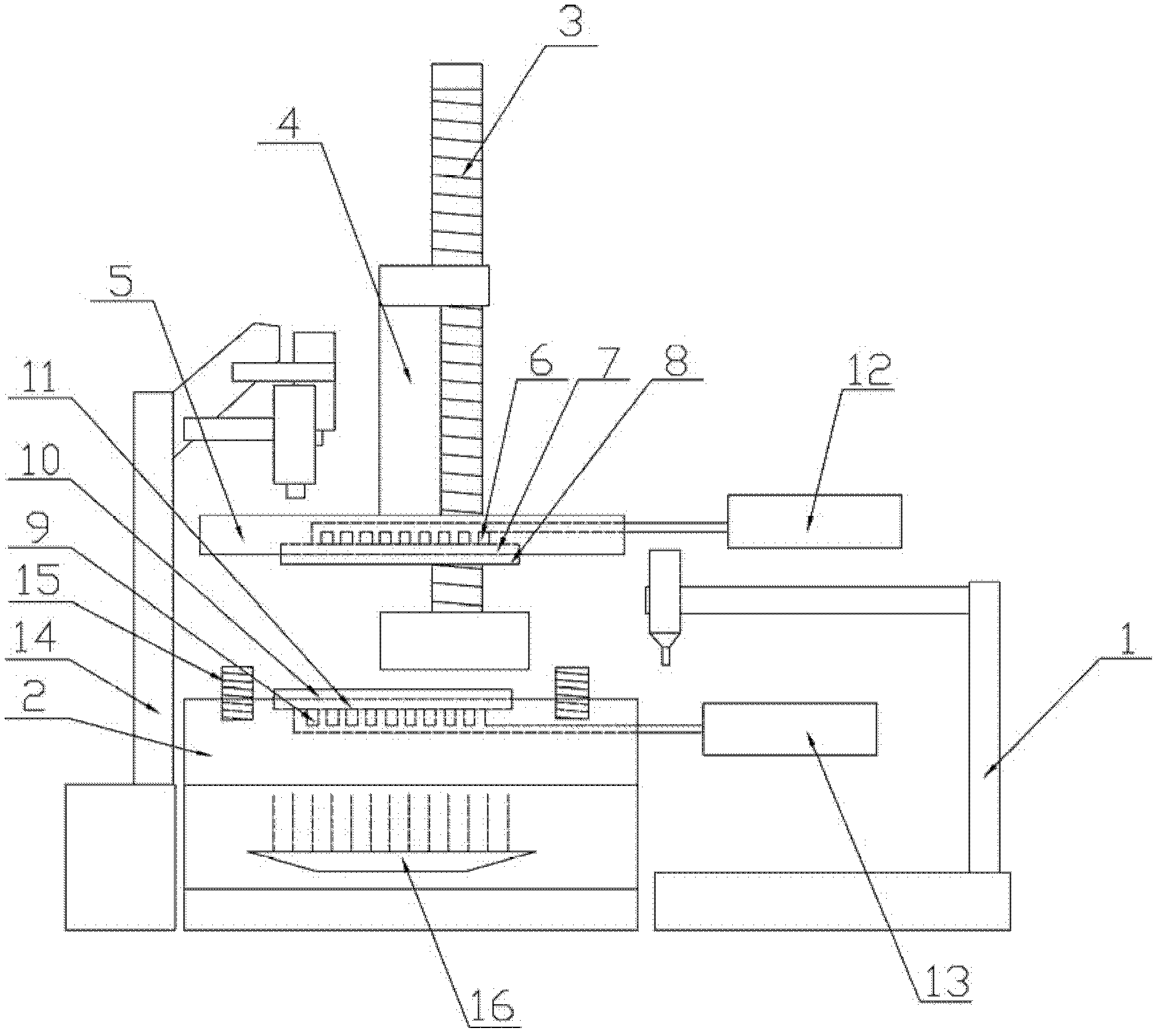

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0025] figure 1 It shows a schematic structural view of the alignment bonding device according to the embodiment of the present invention, which includes a glue dispensing system 1 and a bonding system. The bonding system is used for bonding two substrates, which specifically includes a workbench 2 and a 2, the lower laminating board 10 is placed on the workbench 2, and the upper laminating board 8 is placed on the lifting module. The dispensing system 1 injects UV resin adhesive on the upper surface of the lower laminating board 10, and the laminating system guarantees that When the upper surface of the plywood 8 is parallel to the lower surface of the lower plywood 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com