Method for detecting pupil plane transmittance distribution of photoetching equipment

A technology of lithography equipment and detection method, which is applied in the detection field of pupil surface transmittance distribution, can solve the problems of cumbersome operation and long detection time, and achieve the effects of ensuring imaging contrast, short detection time, and convenient detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

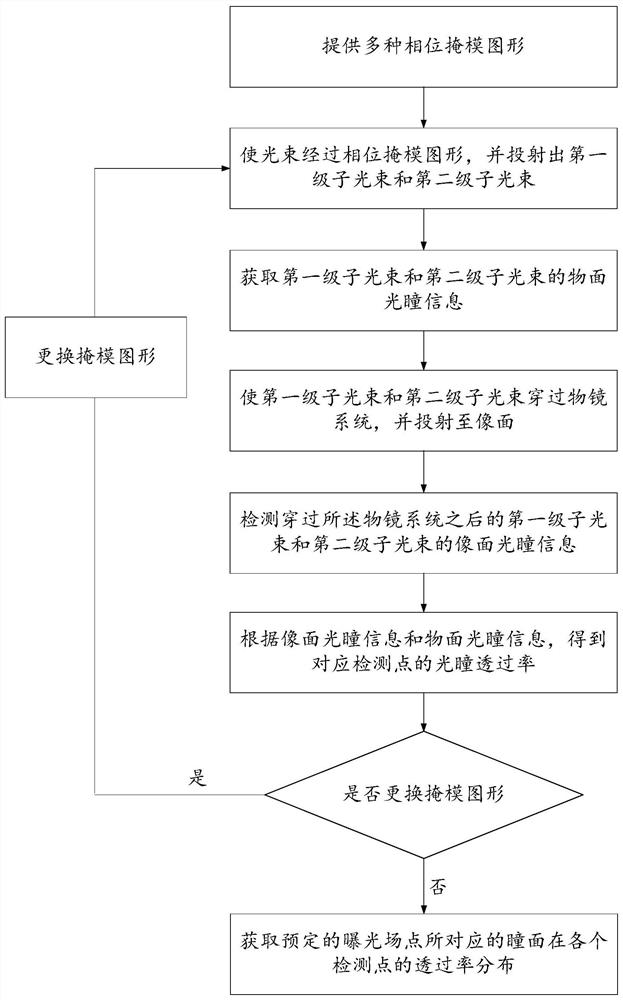

[0052] The core idea of the present invention is to provide a method for detecting pupil transmittance distribution of lithography equipment, including:

[0053] Provide a variety of phase mask patterns;

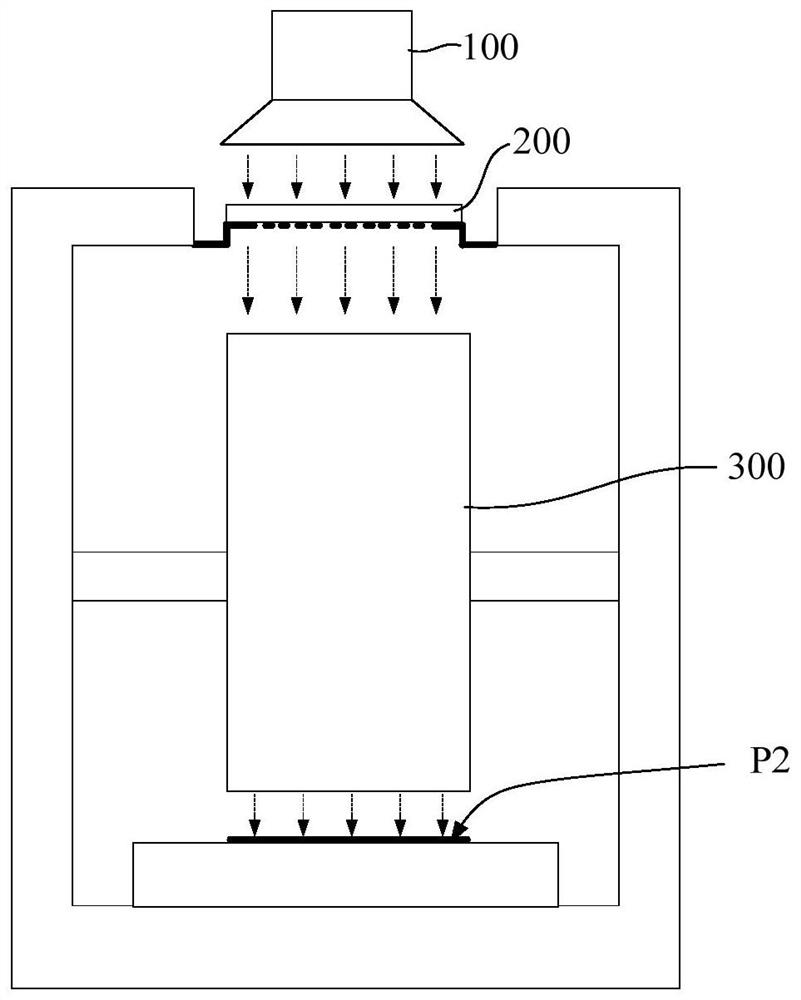

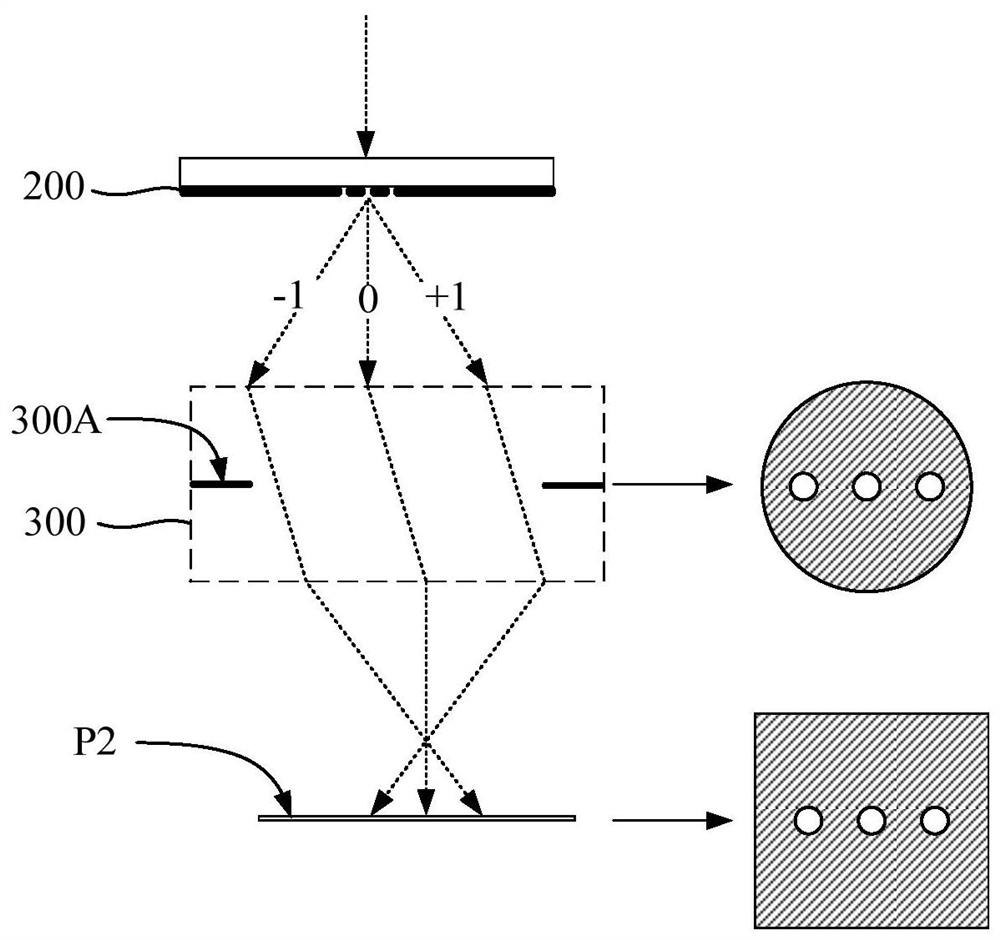

[0054]A light beam is provided by an illumination system, and the light beam is sequentially passed through each phase mask pattern to project a first-level sub-beam and a second-level sub-beam, wherein the second-level sub-beams projected by different phase mask patterns correspond to at different locations on the object plane;

[0055] obtaining object plane pupil information of the first-order sub-beams and the second-order sub-beams projected by each phase mask pattern before passing through the objective lens system;

[0056] The first-order sub-beams and the second-order sub-beams projected from each phase mask pattern are sequentially passed through the objective lens system to be projected onto the image plane, and the first-order sub-beams and the second-order su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com