Shielded cable deconcentrator

A technology of shielded cables and splitters, which is applied in the direction of cable joints, cable accessories, cable installation, etc., and can solve the problems of damaging the insulation isolation of cables and the structural integrity of electromagnetic isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

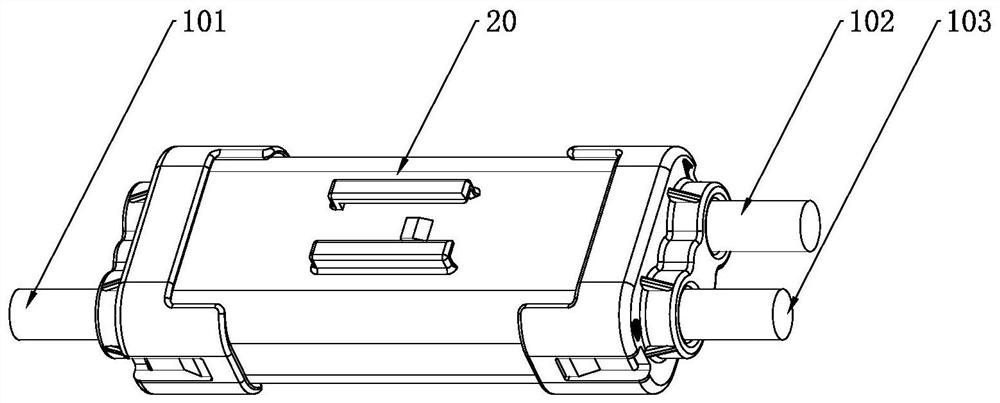

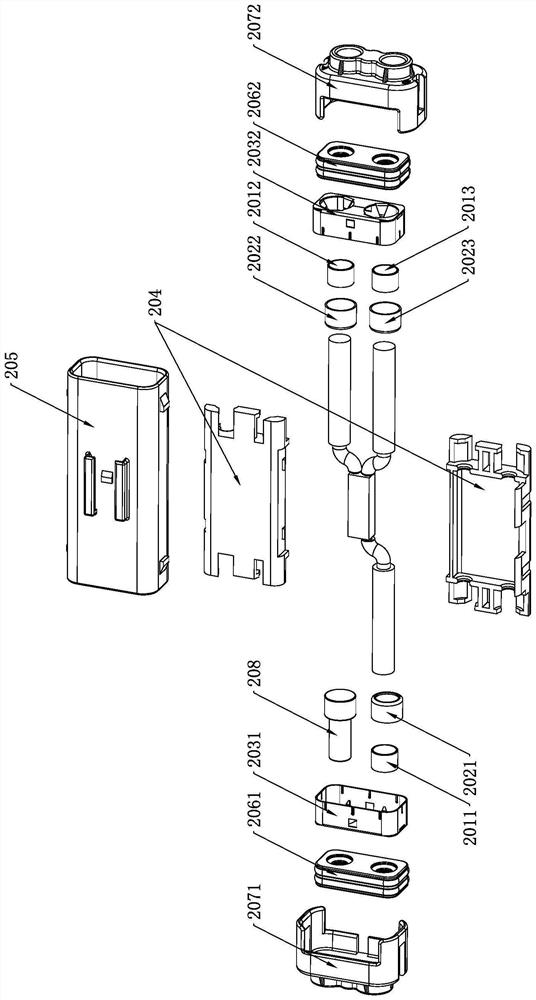

[0036] see Figure 1 to Figure 9 , is an embodiment of a cable assembly using a splitter of the present invention. This embodiment is used to realize the connection from one shielded cable to two shielded cables. The cross section of the splitter used in this embodiment is approximately rounded rectangle.

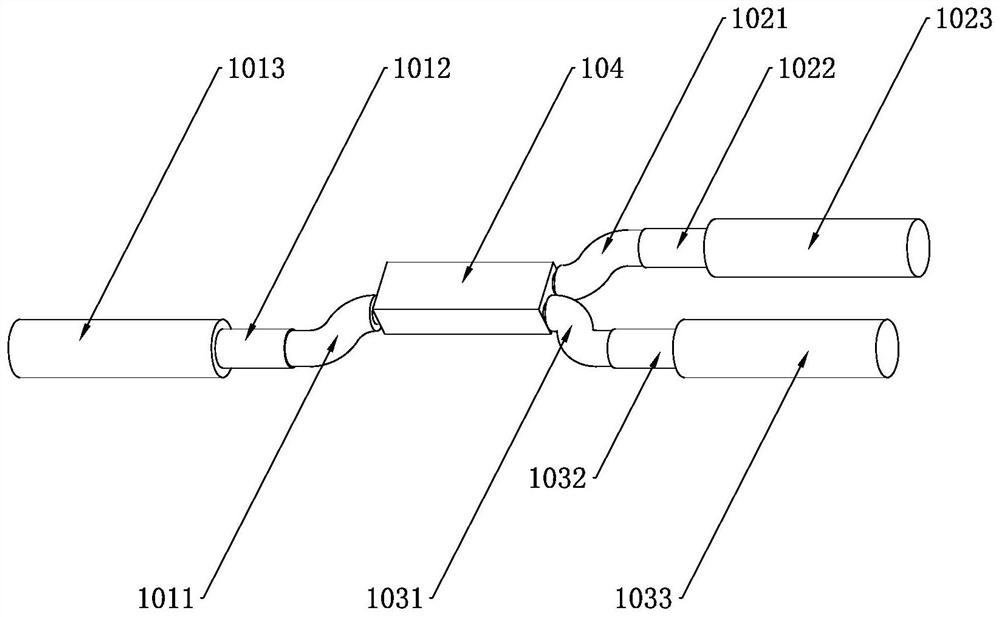

[0037] figure 2 A non-limiting example of three first shielded cables 101 , second shielded cables 102 and third shielded cables 103 spliced together is shown. The electrical conductors of the three shielded cables are joined together by existing techniques such as cold crimping, soldering or sonic welding to form the connector 104 . To enable the connection of the electrical conductors, the outer sheaths 1013, 1023, 1033, the shielding layers 1012, 1022, 1032 and parts of the inner insulating layers 1011, 1021, 1031 are removed from the electrical conductors. At the same time, in order to maintain electrical insulation from the electrical conductor, the shielding lay...

Embodiment 2

[0045] see Figure 10 to Figure 18 , is another embodiment of a cable assembly using a splitter of the present invention. This embodiment is used to realize the connection from one shielded cable to two shielded cables. The appearance of the splitter used in this embodiment is similar to a funnel shape.

[0046] Figure 11 A non-limiting example of three first shielded cables 101 , second shielded cables 102 and third shielded cables 103 spliced together is shown. The difference between this embodiment and Embodiment 1 is that: in this embodiment, the axis of the first shielded cable 101 is located between the axis of the second shielded cable 102 and the axis of the third shielded cable 103 .

[0047] The three shielded cables 101, 102, and 103 connected together are installed on the splitter 20 to form a cable assembly, and the splitter provides the cable assembly with a channel for accommodating the connection position of the shielded cables and overall reinforcement an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com