Split type crossed guide rail sliding block

A cross-rail, split-type technology, applied in the field of track transmission, can solve problems such as unscientific mechanical structure, damage, and force bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

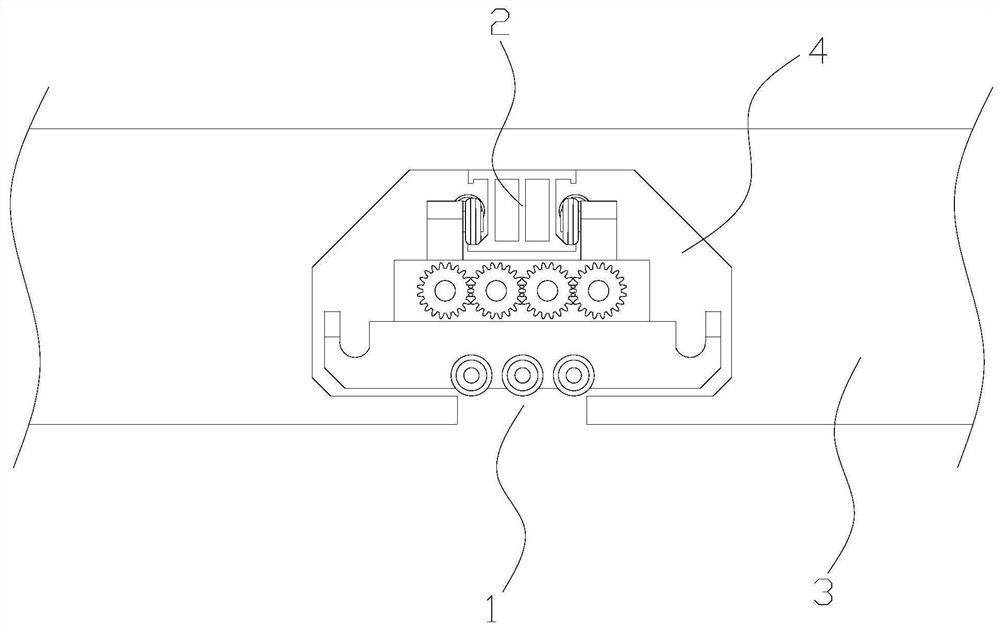

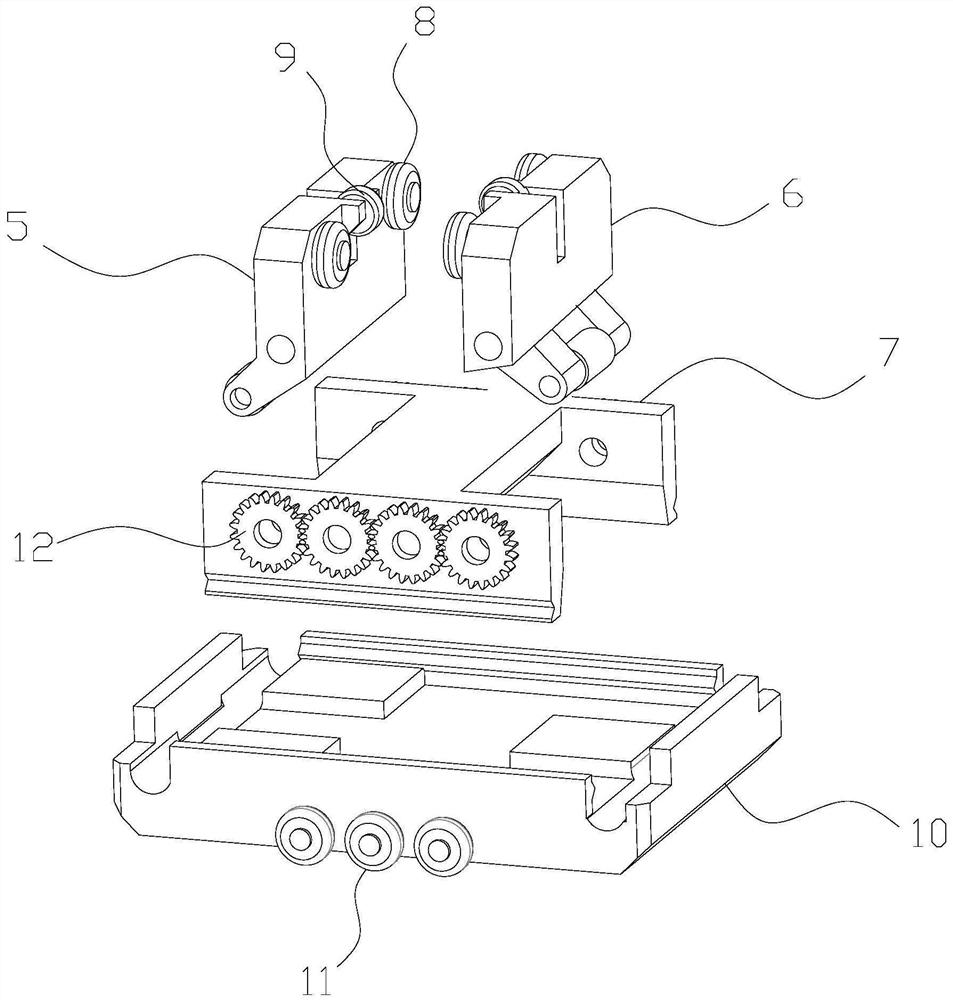

[0041] see Figure 1 to Figure 4 , the present invention provides a split-type cross guide rail slider, including a slider 1 and vertical rails 2 and cross rails 3 arranged crosswise;

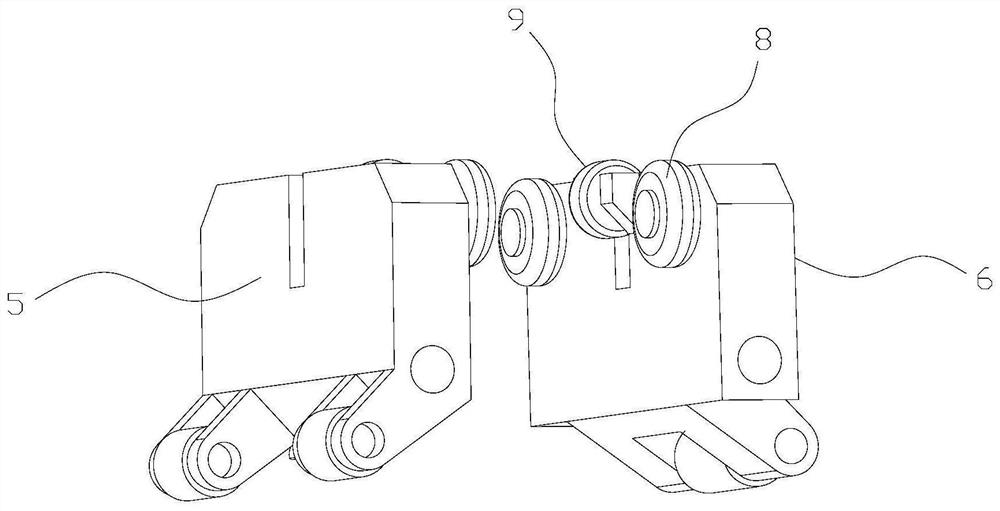

[0042] Wherein, the sliding block 1 includes a longitudinal sliding module and a horizontal sliding module; the longitudinal sliding module is composed of a longitudinal sliding seat 7, a left swing arm 5, a right swing arm 6, a longitudinal guide wheel 8, and a linkage gear set 12; the left swing arm 5 and the right swing arm 6 are respectively connected to the lateral left and right sides of the longitudinal sliding seat 7 through pin shaft rotation, so that the left swing arm 5 and the right swing arm 6 can be clamped or loosened to swing; the left swing arm 5 and the right swing arm 6 A torsion spring is provided between the longitudinal sliding seat 7 to make it (not shown) have a clamping and swinging tendency; the bottom ends of the left swing arm 5 and the right swing arm 6 are inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com