Cam type conversion guide rail sliding block

A technology of changing guide rail and cam type, which is applied in the field of rail transmission, can solve the problems of small load, inability to intersect the arrangement of guide rails, and inability to freely switch sliders, etc., and achieve the effects of strong load capacity, smooth rolling, and scientific and reasonable configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

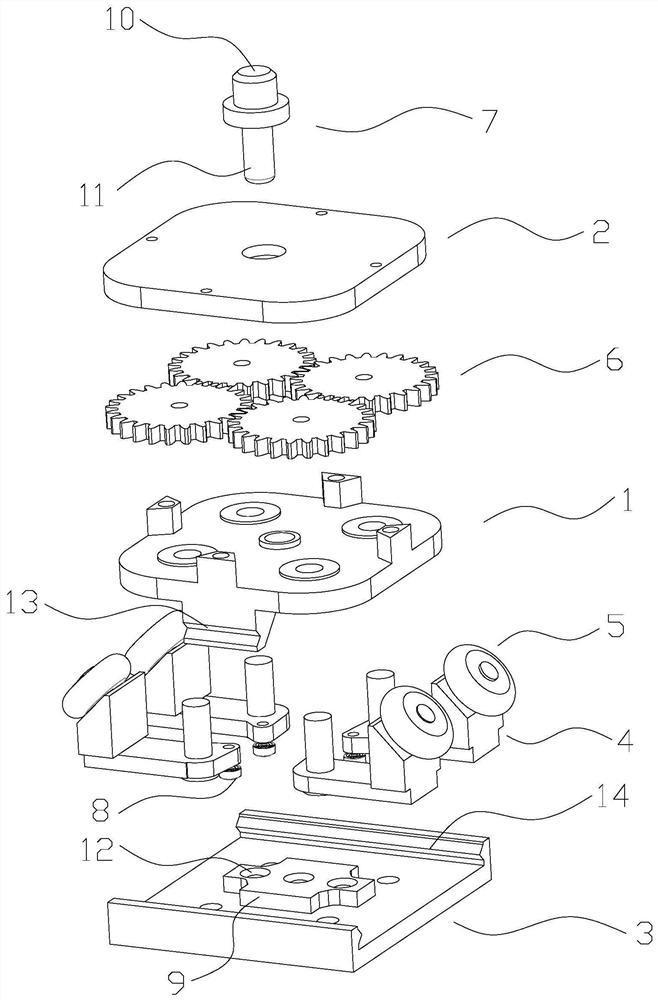

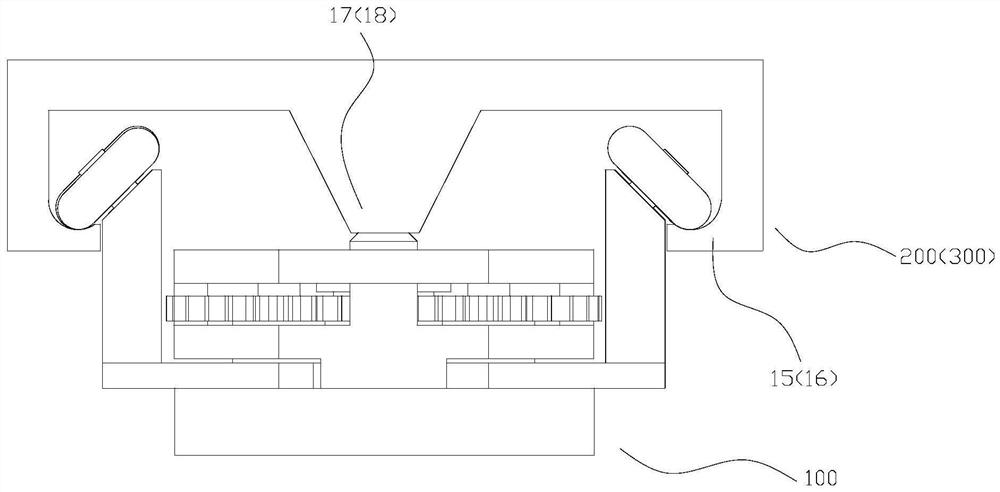

[0041] see Figure 1 to Figure 4 , the present invention provides a cam-type conversion guide rail slider, a slider 100 and cross-arranged longitudinal rails 200 and cross rails 300;

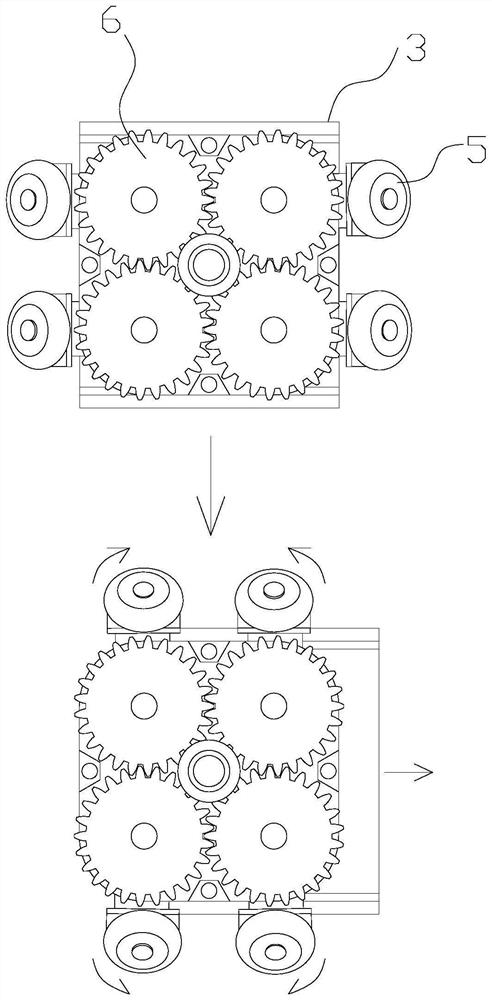

[0042] Wherein, the sliding block 100 includes a base 1, a cover 2, a flange sliding table 3, a swing claw 4, a guide wheel 5, a torsion spring (not shown), a return spring (not shown), a gear 6 and a locking pin 7 The four swing claws 4 are rotationally connected with the four corners of the abutment 1 through pin shafts, so that the four swing claws 4 can swing at 90° at the four corners of the abutment 1, and each swing claw 4 is provided with a swing terminal 8 at the bottom of the swing. The terminal 8 and the swing claw 4 swing synchronously around the pin shaft, and a torsion spring is provided between the swing claw 4 and the base 1; a pin hole is provided in the center of the base 1; On the base 1 and correspondingly connected to the pin shaft transmission of each swing claw 4, it rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com