A heavy-duty cross guide rail four-bar mechanism slider

A four-bar mechanism and cross guide rail technology, applied in the field of track transmission, can solve the problems of small load, non-intersecting arrangement of guide rails, and inability to freely switch sliders, etc., and achieve the effect of strong load capacity and guaranteed sliding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

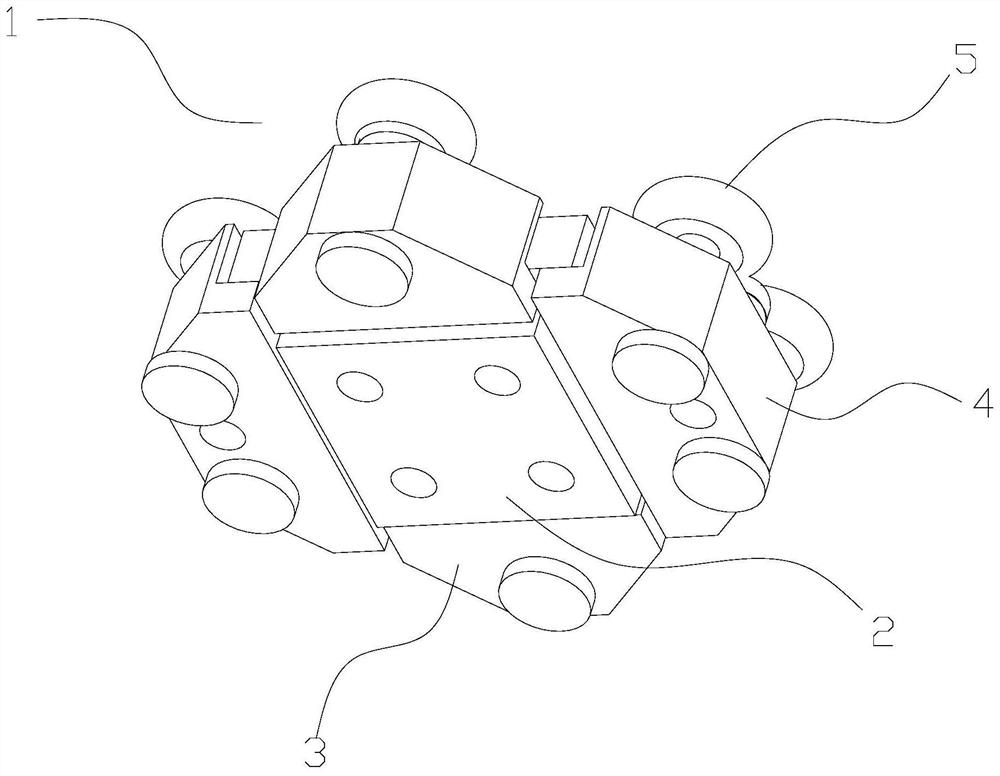

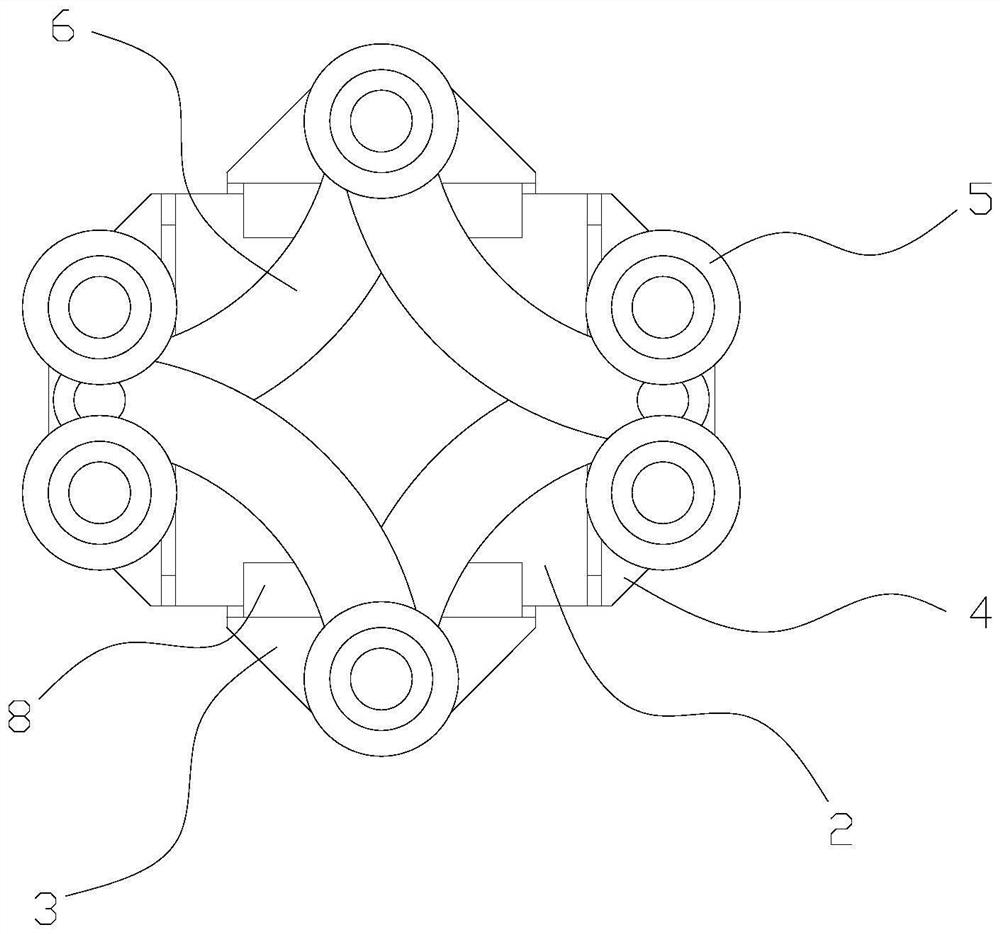

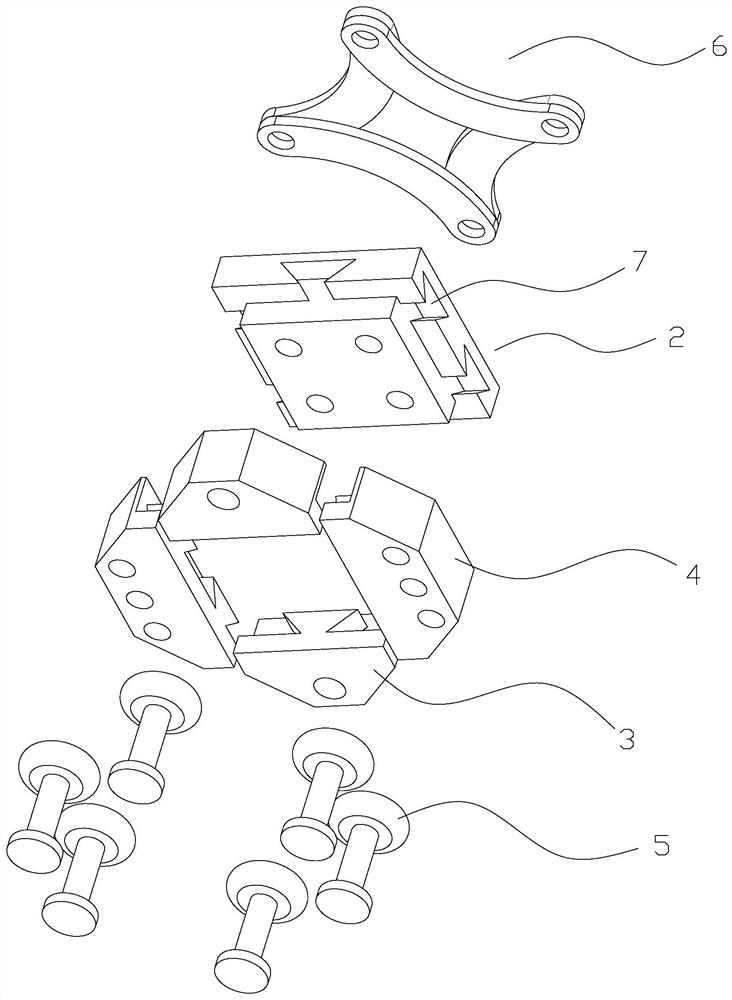

[0037] see Figure 1 to Figure 3 , the present invention provides a heavy-duty cross guide rail four-bar mechanism slider, including a slider 1 and longitudinal rails 11 and cross rails 12 arranged crosswise; wherein, the slider 1 includes two longitudinal sliding units 3, two lateral sliding units Unit 4, slider main body 2, four-bar mechanism 6, elastic member 8 and guide wheel 5; two longitudinal sliding units 3 are respectively slidably connected with slider main body 2 in the longitudinal direction, and two horizontal sliding units 4 are respectively connected with The slider body 2 is slidingly connected; each longitudinal sliding unit 3 is provided with at least one guide wheel 5, and each horizontal sliding unit 4 is provided with two guide wheels 5 arranged in the longitudinal direction; the two longitudinal sliding units 3 and two horizontal sliding units 4 are respectively linked by a four-bar mechanism 6, and the four-bar mechanism 6 is composed of four connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com